G10/10mm/Silicon Nitride Polishing Ceramic Balls/INNOVACERA

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Brand name

- INNOVACERA

- Payment Terms

- L/C,T/T,Western Union

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Ceramics

Innovacera Advanced CO.,ltd

- Verified Certificate

-

11

| Product name | G10/10mm/Silicon Nitride Polishing Ceramic Balls/INNOVACERA | Certification | - |

|---|---|---|---|

| Category | Ceramics | Ingredients | - |

| Keyword | silicon nitride balls , si3n4 ceramic balls , si3n4 polishing balls | Unit Size | - |

| Brand name | INNOVACERA | Unit Weigh | - |

| origin | China | Stock | - |

| Supply type | - | HS code | 8547100000 |

Product Information

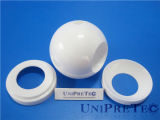

G10/10mm/Silicon Nitride Polishing Ceramic Balls/INNOVACERA

Silicon nitride is a chemical compound of silicon and nitrogen. It is a hard ceramic having high strength over a broad temperature range, moderate thermal conductivity, low coefficient of thermal expansion, moderately high elastic modulus, and unusually high fracture toughness for a ceramic.

Features:

Density 3.25 g/cm3 (59% lower than steel)

Excellent wearability

Max working temperature up to +800°C

Low coefficient of thermal expansion

Very high hardness Hv 1400

Nonmagnetic

Electrical isolating

Self-lubricating

Excellenct corrosion resistance

Applicable for high speed bearings

Application:

Silicon Nitride (Si3N4) Ceramic Balls are formed from a new material suitable for applications where high loads, high speeds and extreme temeratures are factors. Long life and the need for minimal lubrication make this material appropriate for extreme applications. Silicon Nitirde is non-porous, non-magentic, non corrosive, lighter than steel and, in ball form, is harder than steel. Because ceramic balls are non-porous they are virtually frictionless and are capable of spinning faster than steel balls.

Company Info:

Innovacera develops and manufactures products made of technical ceramics for customer-specific applications.

Starting with problem analysis and generation of ideas, Innovacera carries out projects in which cost-efficiency is of paramount importance. Innovacera produces prototypes, small and larger series of custom made products in-house.

Processing equipment:

Precision grinding and machining

CNC machining and grinding

Lapping and polishing

Threading

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | L/C,T/T,Western Union | Shipping time | Negotiable |

- President

- lalal

- Address

- Unit 4G,West Side,Lianchang bldg,No.6-8 Huli Avenue,Huli District,Xiamen,Fujian,China,361004

- Product Category

- Ball Bearings

- No. of Total Employees

- 1-50

- Company introduction

-

Innovacera offers a full range of solutions for supporting parts during sintering in reducing or oxidizing atmospheres up to 1800ºC. Innovacera has the industry's broadest range of manufacturing methods - including vacuum forming, casting, pressing and CNC machining. Mullite, alumina and alumina-zirconia compositions are available for applications in sintering of technical ceramic, electronic ceramic, and powder metal parts.

- Main Product

China

China