Custom Machined Parts/Boron Nitride Slab/INNOVACERA

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Brand name

- INNOVACERA

- Payment Terms

- L/C,T/T,Western Union

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- boron nitride slab, custom machined bn

- Category

- Ceramics

Innovacera Advanced CO.,ltd

- Verified Certificate

-

11

| Product name | Custom Machined Parts/Boron Nitride Slab/INNOVACERA | Certification | - |

|---|---|---|---|

| Category | Ceramics | Ingredients | - |

| Keyword | boron nitride slab , custom machined bn | Unit Size | - |

| Brand name | INNOVACERA | Unit Weigh | - |

| origin | China | Stock | - |

| Supply type | - | HS code | 8547100000 |

Product Information

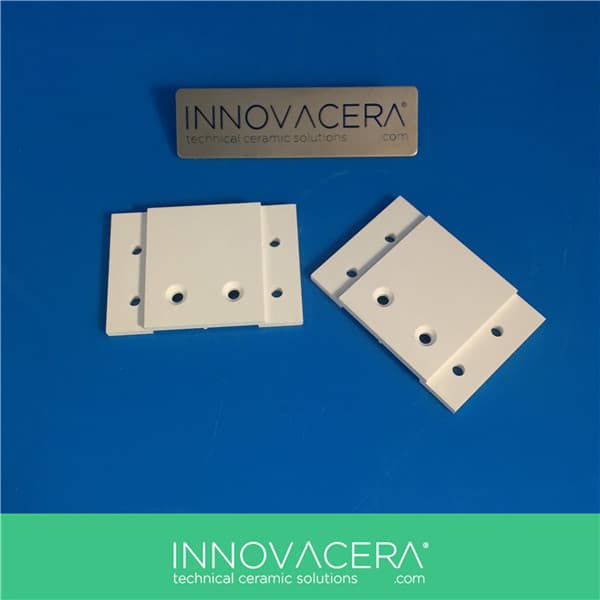

Custom Machined Parts/Boron Nitride Slab/INNOVACERA

Boron Nitride is a hot pressed hexagonal Boron Nitride. This material exhibits a unique combination of chemical, electrical, mechanical and thermal properties, making it suitable for a wide range of high-performance industrial applications. Boron Nitride is an advanced synthetic ceramic material provides unique properties such as from high heat capacity and outstanding thermal conductivity combined with easy machinability and superior dielectric strength. Boron Nitride can easily be machined to close tolerances in virtually any shape. After machining, it is ready for use without additional heat treating or firing operations. In inert and reducing atmospheres, Boron Nitride will withstand temperatures over 2,000°C. It is not wet by most molten metals and slags and can therefore be used as a container for most molten metals including aluminium, cryolite, sodium, iron, steel, silicon, boron, tin germanium and copper.

Features:

Easily Machinable

Exceptional Heat Resistance

High Thermal Conductivity

Low Thermal Expansion, Excellent Thermal Shock Resistance

Outstanding Electrical Insulation - even at high temperatures

High wet resistance to molten metals, slags and glass

Extreme Corrosion and Wear Resistance

Processing details:

Hot pressing is a way of producing boron nitride ceramic , which are fully dense and in pure single-phase form. Hot pressing limits the size and complexity of shapes which can be produced, to shape these diamond grinding is used.

Application:

Break rings for continuous casting of metals

Refractory applications

Continuous casting

Deck plates

Heat treatment fixtures

High temperature lubricant

High temperature valves

Molds/mold release agent

Motel metals and glass casting

Nozzles for transfer or atomization

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | L/C,T/T,Western Union | Shipping time | Negotiable |

- President

- lalal

- Address

- Unit 4G,West Side,Lianchang bldg,No.6-8 Huli Avenue,Huli District,Xiamen,Fujian,China,361004

- Product Category

- Ball Bearings

- No. of Total Employees

- 1-50

- Company introduction

-

Innovacera offers a full range of solutions for supporting parts during sintering in reducing or oxidizing atmospheres up to 1800ºC. Innovacera has the industry's broadest range of manufacturing methods - including vacuum forming, casting, pressing and CNC machining. Mullite, alumina and alumina-zirconia compositions are available for applications in sintering of technical ceramic, electronic ceramic, and powder metal parts.

- Main Product

Related Products

Ceramic Fiber Paper

Ceramic Fiber Blanket

refractory ceramic fiber blankets

Hot Pressed Hexagonal BN Boron Nitride Ceramic Crucible

Zinc oxide (ZnO) ceramic target

China

China