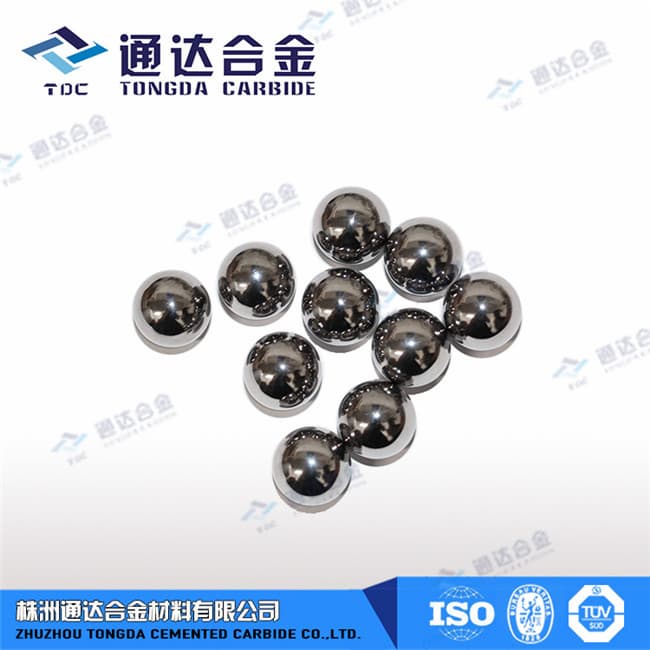

Tungsten Carbide Valve Ball

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Brand name

- TDC

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- tungsten carbide valve ball, tungsten valve ball, carbide valve ball, cemented carbide valve ball

- Category

- Other Minerals & Metallurgy Products

Zhuzhou Tongda Cemented Carbide Co., Ltd

- Verified Certificate

-

10

| Product name | Tungsten Carbide Valve Ball | Certification | - |

|---|---|---|---|

| Category | Other Minerals & Metallurgy Products | Ingredients | - |

| Keyword | tungsten carbide valve ball , tungsten valve ball , carbide valve ball , cemented carbide valve ball | Unit Size | - |

| Brand name | TDC | Unit Weigh | - |

| origin | China | Stock | - |

| Supply type | - | HS code | - |

Product Information

Tungsten carbide valve ball is an important part of globe valve , globe valve can make use of the handle or other drive means rotating sphere 90. So that the hole of the ball and the valve overlap or vertical centerline of the channel, to achieve the valve fully open or fully closed action, usually working in harsh environments. tungsten carbide valve ball with high hardness, wear resistance, corrosion resistance and high temperature, etc., and therefore mainly used in all kinds of sealing work, such as: pump, thermal power plant ash slagging water systems, fluid seal rotating ball.

Tungsten carbide valve ball for conventional pump

Valve ball, the role of a one-way valve to control the flow of oil flow, is in a very poor conditions of work. Multi-component working medium is air, water, oil, sand, wax, resin and asphalt, is a random change and non-uniform three-phase medium. Pumping liquid carry some mechanical impurities at high speed flows violently scour the ball, the ball and seat, has produced hit between the hood, a large quantity of oil wells in the sand, make the ball and seat sealing surface between the damage more rapidly, this damage is a mechanical wear. In most wells all contain corrosive medium, which valve bal is particularly serious corrosion damage. Crude oil contains H2S, Cl- ,salt, alkali and other,so chemical or electrochemical reactions can occur with metal, the metal from corrosion. In the dual role of mechanical abrasion and chemical corrosion, precision ball and seat drop, sealing destroyed, its performance for many irregular surface pitting, flaking, mesh ditch, thereby enabling the valve is fully failure, significantly decreased pump efficiency. Make tungsten carbide as the main material can better adapt to pump operating conditions. Obviously, for the harsh conditions pump, manufactured with tungsten carbide valve ball valve is an ideal material. In short, tungsten carbide valve ball used in pump, both in diluted oil, or heavy oil, high sand, wax wells, or wells rich in corrosive media,will produce good results, and will have a broad application prospect.

The performance of tungsten carbide valve ball

1. Good physical properties. tungsten carbide valve ball has characteristics of high hardness, strong resistance level impact, high temperature resistance, erosion, high abrasion (wear resistance of 15 to 20 times higher than the best high-speed steel).

2. Chemical stability. tungsten carbide valve ball is antioxidant, anti-corrosion to a variety of media (acid, alkali, salt, various gases, etc.) .

3 Density. The proportion of tungsten carbide is16.5-18.75g/cm3,higher than the proportion of steel increased by more than 70%, the whereabouts of the ball will significantly improve the speed, make the performance improved, and is conducive to the normal operation of the valve of the ball.

4 The life of tungsten carbide valve ball is higher than ordinary steel valve ball , and it is widely used in petroleum, chemical and power industries.

Tungsten carbide valve ball sphere finishing

Tungsten carbide valve ball as the opening and closing parts of the seal, tungsten carbide valve ball the should have a sealing surface , roundness and roughness of tungsten carbide valve ball influnt the sealing performance, the ball must be spherical surface finishing. Improve grinding efficiency tungsten carbide valve ball requires the use of closed milling method. Composite slurries and composite abrasive can effectively improve the grinding media and abrasive grinding attachment capability and efficiency of the tungsten carbide valve ball. The quicklier Platen speed, and higher the pressure, the higher processing efficiency, but at the same machining accuracy may decline. Roughing to finishing, grinding disc speed, pressure from high to low choice. tungsten carbide valve ball of the final precision decision on ball roundness control process and the surface roughness of the beginning of the research and precision lapping process.

Tungsten carbide valve ball cost is higher, but due to the life of tungsten carbide valve ball higher than steel valve ball several times, can better adapt to the harsh working conditions in the underground, and would reduce leakage and improve pump efficiency and prolong pump inspection cycle , thus the increase in crude oil prices, operating costs savings far cover the cost of increasing the number of tungsten carbide valve ball . Thus, making use of tungsten carbide valve ball has a very substantial economic benefits.

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- shuming

- Address

- zhuzhou,hunan

- Product Category

- Other Minerals & Metallurgy Products

- Company introduction

-

Zhuzhou Tongda Cemented Carbide Co., Ltd is a professional company which is contributed to study and manufacturer and serve carbide wear-resistance material. For many years, our company rely on progressive production equipment and strong technician strength, constantly studying advanced technology from Switzerland, Germany and America, etc. Combining the valuable feedback from customers, taking advantage of local tungsten carbide and ceramic material, has developed various grinding and dispersion parts which had been reached domestic first-class grade.

Our tungsten grinding rotor, pegs, dispersing tray, tungsten carbide dynamic and static ring, cone round turbo, are mainly used to coating, printing, painting, dying and on the equipment of oily product grinding and dispersion process.

All our products were best-sold to twenty more provinces in China, which not only help to solve manufacturer problems for customers sale, but also be honored as foreigner replacement by many customers.

Zhuzhou Tongda Cemented Carbide Co., Ltd is always insisting on the business idea of “integrity industry, brand business, quality development”, and paying attention to the enterprise image and own brand construction. We keep a close relationship with all customers, and consider every client as a mentor, constantly strengthen the communication and cooperation, and provide the perfect service for them.

We focusing on providing the most effective solution for customers, are supposed to be a professional and diversified hard alloy manufacturer. We not only offer the standard products, but also make all kinds of customized proposal to meet customers needs together with customers themselves.

- Main Product

Related Products

High Fin Tube

Metal Sticker for Credit Card

Rare earth oxide include CeO2, La2O3,Sc2O3

HOT Sale Silicon Carbide Crucible for Melting Metal Aluminum

Raw Wool

China

China