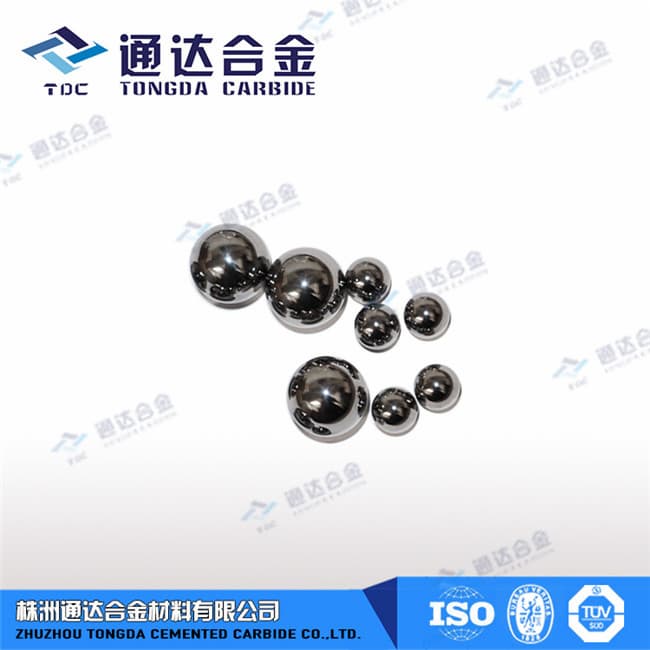

Tungsten Carbide Bearing Ball

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Brand name

- TDC

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Other Minerals & Metallurgy Products

Zhuzhou Tongda Cemented Carbide Co., Ltd

- Verified Certificate

-

10

| Product name | Tungsten Carbide Bearing Ball | Certification | - |

|---|---|---|---|

| Category | Other Minerals & Metallurgy Products | Ingredients | - |

| Keyword | tungsten carbide bearing ball , carbide bearing ball , tungsten bearing ball | Unit Size | - |

| Brand name | TDC | Unit Weigh | - |

| origin | China | Stock | - |

| Supply type | - | HS code | - |

Product Information

Tungsten carbide bearing ball main ingredient is tungsten-cobalt alloy (WC-CO), made of a special working conditions tungsten carbide bearing ball, has high temperature, abrasion resistance, and excellent corrosion resistance and other characteristics, and in high vacuum Magnetically shielded tungsten carbide bearing ball achieved certain results. In addition, due to the tungsten carbide bearing ball with a variety of special properties: such as good wear resistance, red hardness, high strength and high hardness, making it the ideal choice for ball bearings.

Diameter selection of tungsten carbide bearing ball

Ball bearings are standard components of the support shaft, which has a small friction, high efficiency, compact structure, easy maintenance and so on. Bearing clearance (refers to the maximum distance in the absence of load, between the bearing inner and outer ring can move) dynamic load has a significant impact on bearing life, temperature, noise, rated. Usually at the operating temperature of the ball bearing clearance should be close to 0; For large shocks, heavy-duty environment, should be used in a large bearing clearance; For high running accuracy, sound demanding, should be used in smaller bearing clearance. Tungsten carbide bearing ball diameter size is also directly related to the clearance size. Internal clearance is generally non-adjusted bearings shall be subject to professional option, by selecting the appropriate clearance levels and cooperate in order to ensure the normal operation of the bearing. Clearance of the bearing capacity of the bearing, slewing sensitivity, life, vibration characteristics have an important impact on the current traffic control clearance method is matching the right size ball during assembly, through multiple assembly and disassembly, matching up measure axial clearance to meet the requirements.

Action mode of the bearing balls carbide

Tungsten carbide bearing ball extremely broad scope of application, such as: precision bearings, instruments, meters, pumps, machinery and other accessories. tungsten carbide bearing ball is an important part of rolling bearings, tungsten carbide bearing ball mounted in the middle and outer rims of the inner rim, able to withstand greater loads, and can reduce friction and improve efficiency of machinery and equipment.

Tungsten carbide bearing ball machining process

Tungsten carbide bearing ball with high strength, high wear resistance, high-precision, high temperature resistance, corrosion resistance and other characteristics, widely used in the petroleum industry, bearings and so on. Because carbide ball material hardness up HRA87 above, is more than twice the Rockwell hardness of the ball, is difficult to machine materials.

than twice the Rockwell hardness of the ball, is difficult to machine materials. Tungsten carbide bearing ball to go through the following process flow main processes: cold forming or thermoforming process - ball - early research - Lapping - Polishing - Wash Ball --- detection - packaging. Through scientific control stage process, to create a qualified carbide bearing balls.

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- shuming

- Address

- zhuzhou,hunan

- Product Category

- Other Minerals & Metallurgy Products

- Company introduction

-

Zhuzhou Tongda Cemented Carbide Co., Ltd is a professional company which is contributed to study and manufacturer and serve carbide wear-resistance material. For many years, our company rely on progressive production equipment and strong technician strength, constantly studying advanced technology from Switzerland, Germany and America, etc. Combining the valuable feedback from customers, taking advantage of local tungsten carbide and ceramic material, has developed various grinding and dispersion parts which had been reached domestic first-class grade.

Our tungsten grinding rotor, pegs, dispersing tray, tungsten carbide dynamic and static ring, cone round turbo, are mainly used to coating, printing, painting, dying and on the equipment of oily product grinding and dispersion process.

All our products were best-sold to twenty more provinces in China, which not only help to solve manufacturer problems for customers sale, but also be honored as foreigner replacement by many customers.

Zhuzhou Tongda Cemented Carbide Co., Ltd is always insisting on the business idea of “integrity industry, brand business, quality development”, and paying attention to the enterprise image and own brand construction. We keep a close relationship with all customers, and consider every client as a mentor, constantly strengthen the communication and cooperation, and provide the perfect service for them.

We focusing on providing the most effective solution for customers, are supposed to be a professional and diversified hard alloy manufacturer. We not only offer the standard products, but also make all kinds of customized proposal to meet customers needs together with customers themselves.

- Main Product

Related Products

PUP JOINT 4 ½“12.6 PPF EUE 8RD 4FT LONG L80

Ultrafine Copper Powder (PMU) Isotope-Cu63, Cu65

Rare earth oxide include CeO2, La2O3,Sc2O3

VIET NHAT STEEL Corp

Anti loose self locking nut

China

China