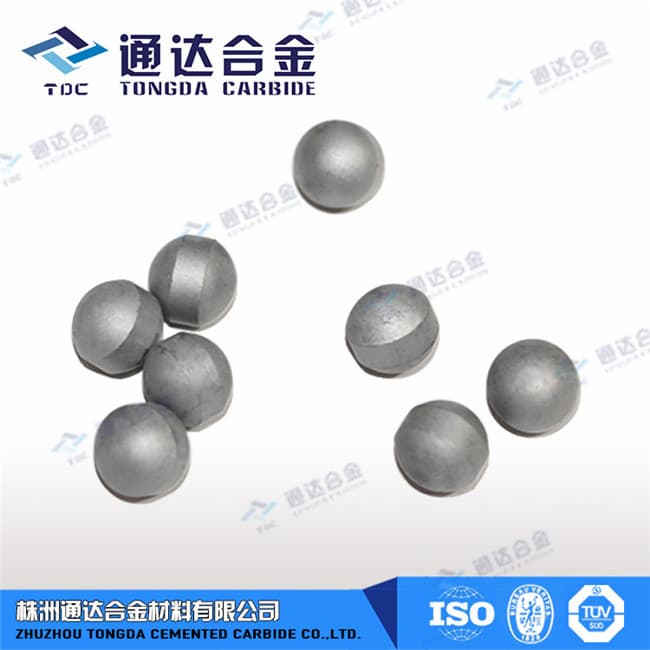

Tungsten Carbide Ball

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Brand name

- TDC

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Other Minerals & Metallurgy Products

Zhuzhou Tongda Cemented Carbide Co., Ltd

- Verified Certificate

-

10

| Product name | Tungsten Carbide Ball | Certification | - |

|---|---|---|---|

| Category | Other Minerals & Metallurgy Products | Ingredients | - |

| Keyword | tungsten carbide balls , cemented carbide ball | Unit Size | - |

| Brand name | TDC | Unit Weigh | - |

| origin | China | Stock | - |

| Supply type | - | HS code | - |

Product Information

Tungsten Carbide Balls Applications

Tungsten carbide balls are also called cemented carbide balls, bearing balls or just simply carbide balls.

The applications of tungsten carbide balls are extremely broad, such as: precise bearing balls, instruments, meters, pen, spraying machines, pumps, machinery parts, valve seals, brake pump, extruding hole, oil, hydrochloric acid lab, hardness measuring instrument, fishing gear, with heavy, ornamented, finished, and some other high-end industry!

High hardness and dimensional stability make tungsten carbide balls the preferred choice for precision hydraulic valves, high-load bearings, inertial navigation systems, ball screws, linear bearings in sideways, gauging and checking instruments, and meters. Tungsten carbide balls are also used for balloting, to work-harden and improve fretting fatigue strength.

Tungsten carbide balls are standard for Rockwell testing, and for Brinell testing of materials in the range of 444-627 HB.

Tungsten Carbide Balls Characteristics

Tungsten carbide balls are ideal for applications where extreme hardness must be accompanied by high resistance to wear and impact. They are well-suited to elevated temperatures, corrosion, humidity, abrasion, and poor lubrication conditions.

Tungsten Carbide Balls Mechanical Properties

• Ultimate tensile strength 220,000 psi

• Ultimate compressive strength 643,000 psi

• Transverse rupture strength 228,000 psi

• Modulus of elasticity 98,000,000

• Density (approx.) 0.54 lb./in.

• Specific gravity 14.85-15.5

• Electrically conductive slightly magnetic

• Low thermal expansion rate

Tungsten carbide balls from Zhuzhou Tongda are tested using a gage that is accurate to ±0.0001 (grades 10, 15 and 25) to insure conformance with standards, as well as individual customer quality requirements. Tungsten carbide balls can be polished into extremely high precision, so it also has a wide use as bearing balls.

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- shuming

- Address

- zhuzhou,hunan

- Product Category

- Other Minerals & Metallurgy Products

- Company introduction

-

Zhuzhou Tongda Cemented Carbide Co., Ltd is a professional company which is contributed to study and manufacturer and serve carbide wear-resistance material. For many years, our company rely on progressive production equipment and strong technician strength, constantly studying advanced technology from Switzerland, Germany and America, etc. Combining the valuable feedback from customers, taking advantage of local tungsten carbide and ceramic material, has developed various grinding and dispersion parts which had been reached domestic first-class grade.

Our tungsten grinding rotor, pegs, dispersing tray, tungsten carbide dynamic and static ring, cone round turbo, are mainly used to coating, printing, painting, dying and on the equipment of oily product grinding and dispersion process.

All our products were best-sold to twenty more provinces in China, which not only help to solve manufacturer problems for customers sale, but also be honored as foreigner replacement by many customers.

Zhuzhou Tongda Cemented Carbide Co., Ltd is always insisting on the business idea of “integrity industry, brand business, quality development”, and paying attention to the enterprise image and own brand construction. We keep a close relationship with all customers, and consider every client as a mentor, constantly strengthen the communication and cooperation, and provide the perfect service for them.

We focusing on providing the most effective solution for customers, are supposed to be a professional and diversified hard alloy manufacturer. We not only offer the standard products, but also make all kinds of customized proposal to meet customers needs together with customers themselves.

- Main Product

China

China