Nichrome Wedge Wire Screen

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- nichrome wedge wire screen, nichrome wedge wire screen manufacturer, nichrome wedge wire screen heating element

- Category

- Other Minerals & Metallurgy Products

Heanjia Super-Metals Co., Ltd

- Verified Certificate

-

9

| Product name | Nichrome Wedge Wire Screen | Certification | - |

|---|---|---|---|

| Category | Other Minerals & Metallurgy Products | Ingredients | - |

| Keyword | nichrome wedge wire screen , nichrome wedge wire screen manufacturer , nichrome wedge wire screen heating element | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | China | Stock | - |

| Supply type | - | HS code | - |

Product Information

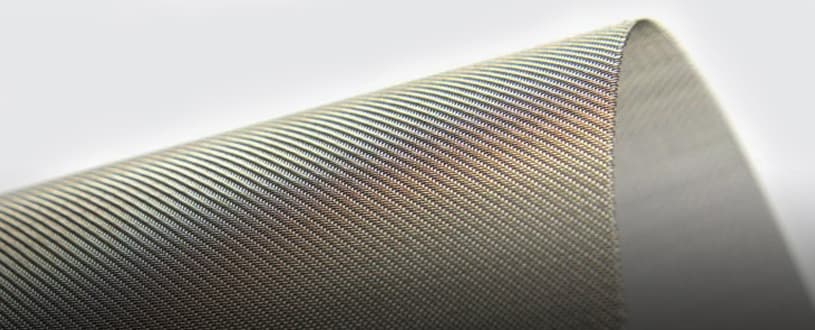

Nichrome Wedge

Wire Screen offers high

creeping resistance and age toughening properties up to 1688oF. It is utilized

in the aeronautics, food processing and mining operations. It offers enhanced

tensile strength after heat processing. For more details

The

Nichrome Wedge Wire Screen is

a blend of surface outlines and supporting outlines, fusion welded at every

joint. The wedge wire screen is manufactured to isolate, categorize, spread,

sustain and filter in multitude of commercial processes, fetching mechanical

strength and durability in the diverse operations.

We

use TIG, MIG and MMA welding methods to produce Nichrome Wedge

Wire Screen. The water stream, laser and plasma are used for

cutting. Our wedge wire screen offers high load bearing competencies, rupturing

and disintegrating strength, above of all, the best functioning of finished

wire screen.

Applications of Nichrome Wedge

Wire Screen

1.Solid-liquid

and Solid-gas isolation

2.Ground

water extraction

3.Crude

oil and natural gas production

4.Water

processing

5.Mining

and aggregate treatment

6.Refining

and petrochemical processes

Properties of Nichrome Wedge

Wire Screen

1.Resistance

to over loading

2.Excellent

screening performance with wide open area percentage

3.High

mechanical strength and durability

4.Resilience

to adhere in the arduous environment

|

Series |

Dimensions |

|

Slot gap

(mm) |

|||||

|

|

A |

B |

|

0.05 |

0.075 |

0.10 |

0.15 |

0.20 |

|

10 SB |

0.75 |

1.30 |

Open

area% |

6.30 |

9.10 |

11.80 |

16.67 |

21.10 |

|

Kg/m2 |

7.26 |

7.05 |

6.85 |

6.50 |

6.18 |

|||

|

11SB |

0.75 |

1.80 |

Open

area% |

6.30 |

9.10 |

11.80 |

16.67 |

21.10 |

|

Kg/m2 |

10.02 |

9.63 |

8.96 |

7.75 |

7.43 |

|||

|

12SB |

1.00 |

1.70 |

Open

area% |

9.10 |

13.04 |

16.70 |

20.00 |

23.08 |

|

Kg/m2 |

10.15 |

9.80 |

9.34 |

9.10 |

8.67 |

|||

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Jialiang Zhao

- Address

- Rong Jing Dao, Rongjing West Road, Yizhuang Technical Economic Development Area

- Product Category

- Other Machinery Parts,Other Minerals & Metallurgy Products

- Year Established

- 1984

- No. of Total Employees

- 51-100

- Company introduction

-

A professional and ISO certified manufacturer and supplier of corrosion resistant and high temperature performance metals and alloys such as Nickel,Kanthal, Inconel, Incoloy, Hastelloy, Nichrome, Nilo, Monel and Cupronickel and more are in line. We produce the alloys in the various standard forms including wire, rod, strip, pipes, sheets, tubes, bars, tape and more in the specific sizes as required by our customers. Our factory is established in China and sales office in Seattle, USA. We have worked with the diverse of industrial sectors for example aerospace, marine, automotive, nuclear, power production, pollution control and chemical engineering. Customers are assured of receiving fully tested products for their applications. Speak with our sales executive today.

- Main Markets

-

North Korea

North Korea

- Main Product

Related Products

sandwich(Mineral,EPS,Glasswool,Urethane)Panel

API 5CT Coupling

Raw Wool

Heat Resistant alloy Rubber blade v plough belt cleaner

Rare earth oxide include CeO2, La2O3,Sc2O3

China

China