Special Indirect Cooling Type

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- South Korea

- Brand name

- Special Indirect Cooling type

- Payment Terms

- L/C,T/T

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

Masang Machinery Co., ltd.

- Verified Certificate

-

9

| Product name | Special Indirect Cooling Type | Certification | - |

|---|---|---|---|

| Category |

Plastic Product Making Machinery

Plastic Rolling Machinery |

Ingredients | - |

| Keyword | indirect cooling type , scale free , stable machine , south korea indirect cooling | Unit Size | 500.0 * 780.0 * 850.0 mm |

| Brand name | Special Indirect Cooling type | Unit Weigh | 85 mg |

| origin | South Korea | Stock | - |

| Supply type | - | HS code | - |

Product Information

As a matter of fact, the Super Tornado technology should be applied for the Auto Master with the mold (which’s using temperature under 100℃) , but in case of using temp. above 100℃ in the mold, we’re strongly suggesting you to choose the Special Indirect Cooling system with our Auto Master.

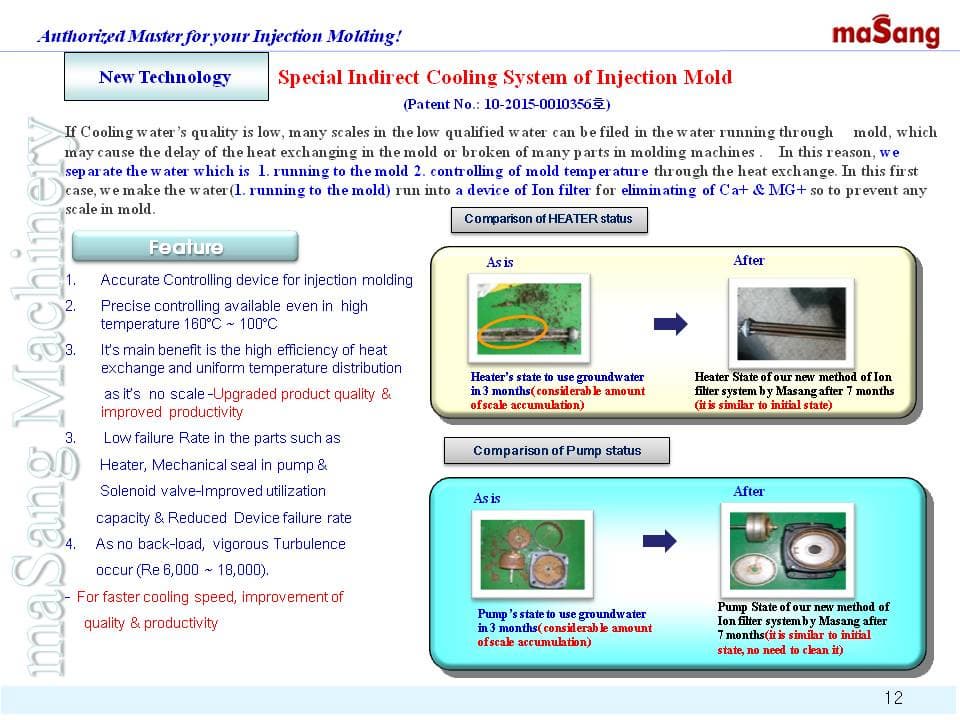

If cooling water’s quality is not clean enough, much scales in the cooling water will be gathered, which

surely cause the delay of the speed of heat exchanging in the mold and huge maintenance cost in your molds. That’s why we’ve designed and developed our own new method, that is, we separate the cooling water by our device ( heat exchanger ) 1. running into the mold 2. controlling of the temperature In the first water ( 1. running into the mold) the water is passed into a device of Ion filter for eliminating of Ca+ , MG+, in the water to prevent any scales in the mold and then flown into mold without any scales,(Patent No. : 10-2015-0010356)

as it’s no scale -Upgraded product quality & improved productivity

4. Low failure Rate in the parts such as Heater, Mechanical seal in pump &

Solenoid valve-Improved utilization capacity & Reduced Device failure rate

5, For no back-load, vigorous Turbulence occuring (Re 6,000 ~ 18,000).

- For faster cooling speed, much improvement of quality & productivity

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | L/C,T/T | Shipping time | Negotiable |

- President

- Lim, Chae-bok

- Address

- 508-7, Tangjeong-dong, Kunpo-city, Kyunggi-do

- Product Category

- Plastic Product Making Machinery,Plastic Rolling Machinery

- Year Established

- 1995

- No. of Total Employees

- 1-50

- Company introduction

-

1.We’re a leading manufacturer of Automatic Molding Temperature Controller (MTC) with R & D in house through our 30 year’s engineering experience in this field since 1985. We’re not only a maker but also provider of total consulting service to our customers in this fied.●2.As we are told to be No. 1 maker, our MTC have been continuously supplied to Korea’s big companies, Samsung, LG, Hyundai Automotive up to now and acknowledged on it’s stable and high quality. That’s why we are so proud we could contributed them to be upgraded as a world major leading brand.●3.Since we have high comprehensive understanding in mold’s cooling and heating system and method, we’ll provide you our total consulting in order to improve your effective productivity.●4.We’ll continuously make development of MTC to improve your injection molding technology and always upgrade our products for your material’s saving, cycle time reducing and the better productivity as No. 1 maker of molding temperature controller in the world.

- Main Markets

-

Japan

Japan

- Main Product

Related Products

PE Foam Sheet Extrusion Line JINSUNG

PVC CASTING TYPE MACHINERY PVC PRODUCTION LINE

PVC decorative film

Plastic Sheet

keli szcx injection blow molding machine

South Korea

South Korea