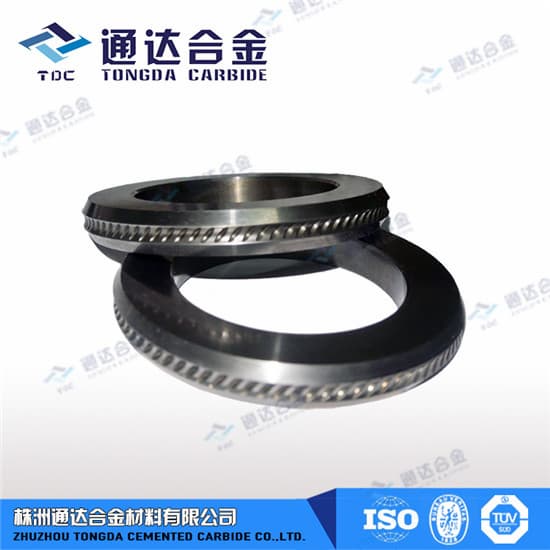

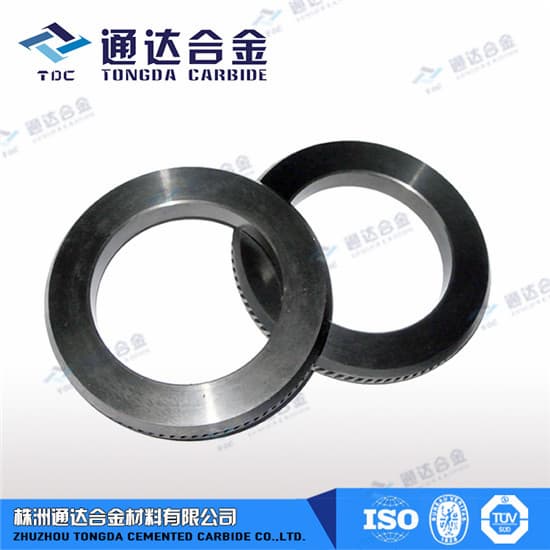

Tungsten Carbide Roll Ring

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Austria,Belarus,Canada,India,North Korea,U.S.A

- Brand name

- Tongda

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

Zhuzhou Tongda Cemented Carbide Co., Ltd

- Verified Certificate

-

9

| Product name | Tungsten Carbide Roll Ring | Certification | - |

|---|---|---|---|

| Category | Other Non-Metallic Mineral & Products | Ingredients | - |

| Keyword | tungsten carbide roll ring , tungsten carbide roller ring , carbide roll ring , roller ring | Unit Size | - |

| Brand name | Tongda | Unit Weigh | - |

| origin | Austria,Belarus,Canada,India,North Korea,U.S.A | Stock | - |

| Supply type | - | HS code | - |

Product Information

Tungsten carbide roll ring has characteristics of good wear resistance, high temperature red hardness, thermal fatigue resistance and thermal conductivity and high strength, it is a key component of high-speed wire rod rolling. Tungsten carbide roll ring is mainly used for high-speed wire rod mill pre-finishing unit, and finishing units, reducing sizing unit, rolling play area and improve the performance of rolling material effect decreases. Tungsten carbide roll ring line production to meet the needs of making various types of high carbon steel, alloy steel and special steel.

Tungsten carbide roll ring material is developed on the basis of the tungsten carbide tool material, it is made of refractory metal compound (WC) as a matrix, and transition metals (Co, Fe, Ni) as the binder phase. Tungsten carbide roll ring has good abrasion resistance, high-temperature red hardness, thermal conductivity and high temperature strength and other characteristics, it has been widely used in making high-speed wire rod, bar, rebar, and other rolling seamless steel pipe production. During normal use, the surface due to the impact of high frequency alternating thermal shock and hot water fog and thermal fatigue cracking, commonly known as crack, different forms of wear or fracture failure is the main reason in this case appears thermal fatigue crack initiation and propagation. When the groove face cracked it must be grinded to prevent crack propagation caused by abnormal breakage roller ring.

Tungsten carbide roll rings performance requirements

When the roller ring used, the roll diameter roller ring is smallest , and line the fastest, roll ring subjected to thermal shock highest frequency. Therefore, it requires roll ring material having excellent abrasion resistance to ensure the dimensions of finished wire after a certain amount of rolling ; and requires a high fracture toughness to resist the thermal expansion of the higher frequency shocks caused thermal fatigue cracks; the same time, need to have a high thermal conductivity to suppress thermal fatigue crack initiation. During use, the maximum operating speed of tungsten carbide roll rings up to 18000 r / min, and rolling up to the maximum temperature of the contact 1200 ℃. It is in this harsh working conditions, the roller ring wear resistance, toughness, resistance to thermal fatigue performance high demands. To achieve these performance requirements, often using coarse-grained low cobalt grades roller ring, such as WC-6% Co.

Tungsten carbide roll ring characteristics

1. Contains a microscopic hard spots, have a high resistance to abrasion

2. The macro-hardness is high, up to 69 ~ 81HRC or more.

3. Material hardening tendency serious.

4. Material with low thermal conductivity.

5. High intensity of the material.

6. Stable chemical properties, very high melting point.

Tungsten carbide roll ring using requirements

Heap of steel rolling process is inevitable accident, the heap of steel rolling various causes overheating will cause the roller ring side, while at the other side of the water-cooled quenching effect, causing the roll surface heat cracks, restoring rolling when this heat leaving the roller ring rapid crack propagation easily cracked. Because rolling at high speed rolling finishing train, the temperature is high, when the stack of steel metal deposited on the roller ring groove around, due to the effect of high temperature molten metal ring attached to the roller surface, forming a "product turtle" phenomenon. In this case, local heating roller ring, resulting in heat stress, heat fatigue easily formed, if the roller ring continued use, the potential cause fracture failure. Remove the stack of steel roll ring, regardless of the groove is available, should be re-grinding, in order to eliminate the stress roll ring to prevent thermal fatigue crack initiation and propagation.

Tungsten carbide roller ring has good heat conduction properties, down less hardness at high temperature, good thermal fatigue resistance, wear resistance, high strength, and other characteristics,so it is suitable for high speed rolling, and it become the good choice for roller ring.

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- shuming

- Address

- zhuzhou,hunan

- Product Category

- Other Minerals & Metallurgy Products

- Company introduction

-

Zhuzhou Tongda Cemented Carbide Co., Ltd is a professional company which is contributed to study and manufacturer and serve carbide wear-resistance material. For many years, our company rely on progressive production equipment and strong technician strength, constantly studying advanced technology from Switzerland, Germany and America, etc. Combining the valuable feedback from customers, taking advantage of local tungsten carbide and ceramic material, has developed various grinding and dispersion parts which had been reached domestic first-class grade.

Our tungsten grinding rotor, pegs, dispersing tray, tungsten carbide dynamic and static ring, cone round turbo, are mainly used to coating, printing, painting, dying and on the equipment of oily product grinding and dispersion process.

All our products were best-sold to twenty more provinces in China, which not only help to solve manufacturer problems for customers sale, but also be honored as foreigner replacement by many customers.

Zhuzhou Tongda Cemented Carbide Co., Ltd is always insisting on the business idea of “integrity industry, brand business, quality development”, and paying attention to the enterprise image and own brand construction. We keep a close relationship with all customers, and consider every client as a mentor, constantly strengthen the communication and cooperation, and provide the perfect service for them.

We focusing on providing the most effective solution for customers, are supposed to be a professional and diversified hard alloy manufacturer. We not only offer the standard products, but also make all kinds of customized proposal to meet customers needs together with customers themselves.

- Main Product

China

China