Rubber conveyor belt repair- how to use repair strip correct

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Brand name

- dipute

- Payment Terms

- T/T

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Rubber Belts

Zhengzhou Dipute Chemical Co.,Ltd.

- Verified Certificate

-

12

| Product name | Rubber conveyor belt repair- how to use repair strip correct | Certification | - |

|---|---|---|---|

| Category | Rubber Belts | Ingredients | - |

| Keyword | conveyor belt repair strip , belt repair strip , rubber repair strip | Unit Size | - |

| Brand name | dipute | Unit Weigh | - |

| origin | China | Stock | - |

| Supply type | - | HS code | - |

Product Information

Rubber conveyor belt repair- how to use repair strip correctly?

We know when conveyor belt damaged , scratched or torn, we have to repair it with repair strip, but how to use repair strip correctly and efficiently? Definitely, to a new comer in the repair industry, you will need a guidance.

Meanwhile, in the forward passage “conveyor belt repair”, we have introduced how to repair a conveyor belt, you can take a check.

Methods for rubber conveyor belt repair

1. First of all,

we will mark the damaged parts,this is for choosing the appropriate repair

strip, we will cut the repair strip according to the size of damaged parts, make

sure that repair strip should be 4cm larger than the damaged parts.

2. Use the angle grinder L1202 accompany with tungsten carbon buffing disc to grind the damaged parts, grinding parts should present a certain radian and no protrusion points.

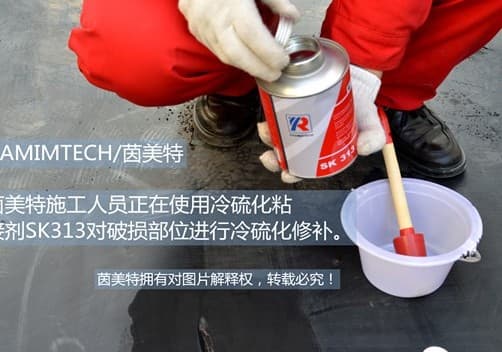

3. Mix cold vulcanizing glue SK811 with hardener , grinding parts should brush the mixture twice, first brush should be entirely dry(at least 30 minutes, however the metal surface at least need a hour). Then the second brush. However the repair strip should brush once only, when both of them have little stickness ( test with finger back), we can glue them.

4. Repair strip should glue along with the marked line from one side to the other side, after finishing all, use the roller stitcher press from inside to outside, after compaction, we can realize the repair.

Attentions:

1. If the damaged parts sunken seriously, we will advice filling them with T2 system, then use the repair strip.

2. Conveyor belt repair parts should brush the cold vulcanizing adhesive mixture twice and repair strip whose semi-cured layer will brush once only.

3. Cold vulcanzing adhesive Sk811 and hardener , and the amount will choose according to the size of damaged parts and avoid the Sk313 solidify and waste.

Choose Ramimtech cold vulcanizing jointing methods to finish conveyor belt repair under normal temperature, repair strip and conveyor belt jointing parts will brush cold vulcanzing adhesive Sk811, which can reach the working strength promptly and once repair can use immediately.

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | T/T | Shipping time | Negotiable |

- President

- Brant Gao

- Address

- NO.1shangdu Road, New Eastern district Zhengzhou Henan 450000 China

- Product Category

- Epoxy Adhesives,Rubber Sheets

- No. of Total Employees

- 1-50

- Company introduction

-

Founded in 1998,Located in Zhengzhou City of Henan Province,China.Zheng Zhou Dipute Chemical Co.,Ltd,which is a professional manufacture & Supplier to provide a complete range of conveyor services and products to the mining and materials handling industry. All of our products have obtain the ISO9001-2008 certification.The excellent quality is reliable and winning a good reputation from our customers around the world. Our professional team consists of skilled belt workers and tradesman, backed up by technical staff with extensive experience in the minerals, mining and heavy industrial sectors.Our goal is to provide solutions to our customers tougest problems in conveyor belt system.

- Main Product

Related Products

door seal strip

General Rubber Sheet

Container Rubber Seal Strip

Pipe Conveyor Belt

S5M rubber synchronous belt timing belt 210 t

China

China