CNC COIL SPRING FORMING M/C (AT-C30/50/80/100/120/160/200)

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- South Korea

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- coil spring, forming machine, spring forming, cnc coil

- Category

- Metal & Metallurgy Machinery

A-Tech Co.,Ltd.

- Verified Certificate

-

10

| Product name | CNC COIL SPRING FORMING M/C (AT-C30/50/80/100/120/160/200) | Certification | - |

|---|---|---|---|

| Category | Metal & Metallurgy Machinery | Ingredients | - |

| Keyword | coil spring , forming machine , spring forming , cnc coil | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | South Korea | Stock | - |

| Supply type | - | HS code | - |

Product Information

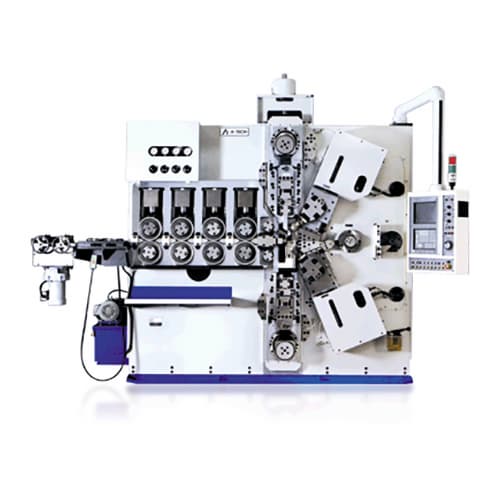

CNC COIL SPRING FORMING M/C (AT-C30/C50/C80/C100/C120/C160/C200 Series)

│ Features of AT-C Series │

- This is an exclusive machine for making coil spring, having a powerful drive and durability- oriented design. And so anyone can operate it easily with simple program.

- As individual axis has its own servo motor, this machine is suitable for both various types of coil spring in small lots and mass production.

- Especially, as mandrel holder and L&R cutting units are attached on one plate and integrated, there is no movement of mandrel holder at all during high pressure cutting, so that it can guarantee production of constant high quality coil spring.

- At it has self-diagnosable function for its each part and can display all conditions & errors on the monitor, users can operate it safely, also adding various options available.

│ SPECIFICATION │

| MODEL | AT-C30 | AT-C50 | AT-C80 | AT-C100 | AT-C120 | AT-C160 | AT-C200 |

| Axis | 7 | 7 | 7 | 7 | 7 | 7 | 7 |

| Wire Capacity(m/m) | 0.8~3.0 | 2.0~5.0 | 2.5~8.0 | 4.0~10.0 |

5.0~12.0 | 6.0~16.0 | 8.0~20.0 |

| Max. OD(m/m) | 60 | 100 | 130 | 150 | 200 | 220 | 270 |

| Feeding Length | unlimited | unlimited | unlimited | unlimited | unlimited | unlimited | unlimited |

| Feeding Speed(n/min) | 150 | 150 | 120 | 100 | 60 | 40 | 30 |

| Production Speed(pcs/min) | 180 | 150 | 100 | 90 | 60 | 40 | 35 |

Min. Spring Index(Dn/d) |

3 | 3 | 3 | 3 | 3 | 4 | 4 |

| Feeding Roller(set) | 3 | 3 | 3 | 4 | 4 | 4 | 4 |

| Mandrel Axis Up/Down | option | option | option | option | option | option | option |

| Main Motor(Total) | 11kw | 14kw | 27kw | 38kw | 58kw | 86kw | 120kw |

| Machine Dimension L×W×H(㎜) |

1300× 1350×1800 |

1600× 1500×1900 |

1600× 1650×2100 |

1700× 1800×2200 |

2280× 2550×2680 |

2280× 2600×2750 |

2600× 3000×2800 |

| Weight(kgs) | 1800 | 3500 | 6000 | 9000 | 13000 | 15000 | 18000 |

| Power supply | 3P 220V ± 10% 50~60Hz | ||||||

│ PRODUCT & PRODUCE │

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Myungho Kim

- Address

- 649-8, Naksan-Ri, Waegwan-Eup, Chilgok-Gun, Gyeoungbuk, Korea

- Product Category

- Manufacturing & Processing Machinery Agents,Metal Bending Machinery,Other Machinery & Industry Equipment

- Year Established

- 1984

- Company introduction

-

A-Tech Co.,Ltd. specializes in wire bending machinery including 2D wire forming machines, 3D wire bending machines, tabletop wire benders, spring machines, spring coilers, spring grinders, spring testers, and spring testing equipment.

- Main Product

South Korea

South Korea