Cross Hatch Cuutter

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Brand name

- BEVS

- Payment Terms

- T/T

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Physical Measuring Instruments

BEVS Industrial Co.,Ltd.

- Verified Certificate

-

10

| Product name | Cross Hatch Cuutter | Certification | - |

|---|---|---|---|

| Category | Physical Measuring Instruments | Ingredients | - |

| Keyword | cross cutter , paint & coating remover , cross hatch cutter , paint cutter | Unit Size | - |

| Brand name | BEVS | Unit Weigh | - |

| origin | China | Stock | - |

| Supply type | - | HS code | - |

Product Information

1. Introduction

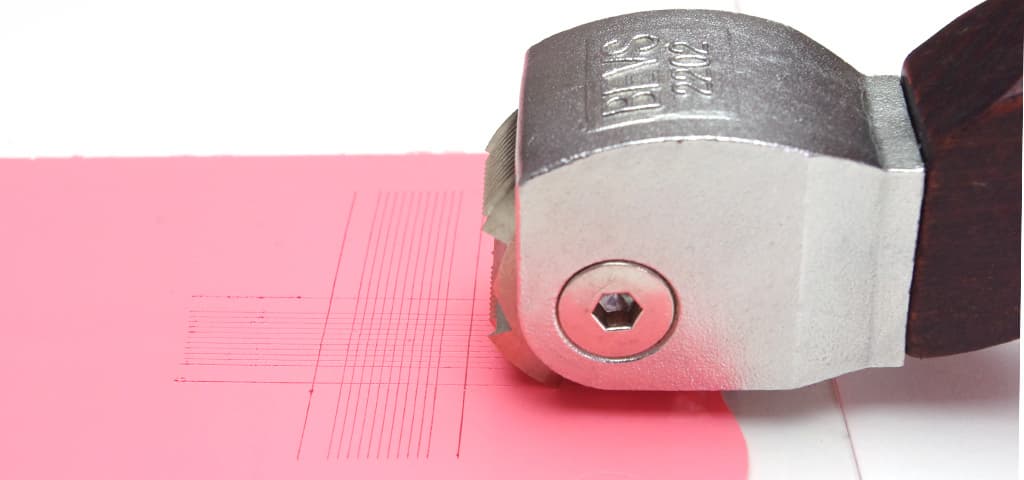

BEVS cross hatch

tester is designed for assessing the resistance of paint or related coatings

to separation from substrates when a

right-angle lattice pattern is cut into the coating, penetrating through to the

substrate.

When applied to

multi-coat system, assessment of the resistance to separation of individual

layers of the

coating from each other may be made.

2. Packing List

2.1

1 x Carrying Case

2.2

1 x Cross Hatch Cutter & Handle

2.3 1 x Magnifier (5X)

2.4 1 x Tape (3M)

2.5 1 x Soft Brush

2.6 1x Certificate of Conformity

3. Specifications

The Cross Cutters

Tester conform with the requirements of: ISO2409-1992,GB/T9286-98,BS3900 E6,

ASTM D3359.

In order to

achieve consistent results it is recommended that the test be conducted in accordance

with the stated test methods.

4. Preparation

for Test

The following guide will provide the user

with a working knowledge of how to conduct the test. These notes should be read

in conjunction with the stated test methods in order to obtain meaningful

results that can be used for comparative purposes.

4.1 Check for correct selection of cutter type:

2202/1 is

designed for hard substrates with a coating up to 60 microns.

2202/2 for

hard substrates up to 60 microns, with the benefit of 11 teeth to produce 100 squares, enables % values to be obtained

from the results.

2202/3 intermediate,

suitable for hard and softer substrates up to 60 microns.

2202/4 for

both soft & hard substrates with a coating thickness from 61 - 120 microns.

2202/6 for

both hard & soft substrates coating thickness 121 - 250 microns.

Obtain Pressure Sensitive Adhesive Tape (for hard substrates).

It is important that

the same specification tape is always used (the grade of tape supplied is the

same as specified in the standard test methods) in order that consistent,

comparable results are obtained.

4.2 Place the coated test panel on a rigid, flat

surface to prevent any deformation of the panel during test.

4.3 Before the test, inspect the cutting edge of

the blade for sharpness and condition. If the panel is of wood or similar

material, make cuts at approximately 45° to the direction of the grain.

4.4 Grip the cutter firmly, place the index finger

(if required) onto the cutter holder to enable even pressure to be applied to

the coating.

4.5 With the blade normal to the test panel

surface, apply uniform pressure on the cutting tool, draw the cutter at a

uniform rate across the surface for a distance of approximately 30 mm All the

cuts shall penetrate to the substrate.

4.6 Repeat the operation, crossing the original

cuts at 90° to them so that a lattice pattern is formed.

4.7 Brush the panel lightly with a soft brush

along each of the diagonals of the lattice pattern.

For hard

substrates proceed to step 4.8.

Soft substrates, carefully examine the

cut area of the test coating in good lighting

using normal or corrected

vision, (a lens of 3 or 5 times magnification maybe used). During the viewing process, rotate the panel so that the

viewing and lighting of the test area are not confined

to one direction.

4.8 If the test is made on hard substrates the

Pressure Sensitive Tape is too be used. (para 4.1 refers)

If beginning a

new series of tests, remove two complete laps of Pressure Sensitive Tape and

discard. Remove an additional length at a steady rate and cut a piece

approximately 75 mm long.

4.9 Place the centre of the tape over the lattice in a direction

parallel to one set of cuts, smooth the

tape into place over the area of the lattice and for a distance of at least 20

mm beyond with a finger.

To ensure good contact with the coating,

rub the tape firmly with a fingertip. The colour of the coating seen through

the tape is a useful indication of overall contact.

4.10 Within 5 minutes of applying

the tape, remove the tape by grasping the free end and pulling it off steadily

in 0.5 s to 1.0 s, at an angle which is as close as possible to 60°. (the 60° refers to the

angle between the tape being pulled off and the tape remaining)

4.11 Retain the tape for

reference purposes, for example by attaching it to a sheet of transparent film.

5. Evaluation of

Results.

The results maybe classified into 6 categories:

Cat

0. The edges of the cuts are clean

and smooth; no squares of the lattice show any detachment.

Cat

1 Detachment of small flakes of

the coating at the intersections of the cuts. A cross-cut area not greater than

5%.

Cat 2 The

coating has flaked along the edges and/or at the intersections of the cuts. A

cross-cut area significantly greater than 5%, but not greater than 15%, is

affected.

Cat

3. The coating has flaked along the

edges of the cuts partly or wholly in large ribbons, and/or it has flaked

partly or wholly on different parts of the squares. A cross-cut area

significantly greater than 15% is affected.

Cat

4. The coating has flaked along the

edges of the cuts in large ribbons and/or some squares have detached partly or

wholly. A cross-cut area significantly greater than 35%., but not significantly

greater than 65%, is affected.

Cat

5 Any degree of flaking that

cannot even be classified by classification 4.

For

multi-coat systems the evaluation should review the interface at which flaking

occurs.

Note.

the categories stated are based on ISO 2409 test method, for more complete definition of test it is recommended that the

user refer to the stated test methods.

6. Limitations.

The Cross Hatch Cutters are not suitable for coatings thicker than 250

microns or for textured coatings.

7. Routine

Maintenance

Inspect the Cross Hatch Cutter for wear to the

edges of the teeth, also any damage.

New cutter teeth have flats machined into the

apex of the teeth, the width of which is nominally 0.05 mm,

Through use the width of the flats will

increase and the cutting edge will loose it’s sharpness, check flat width not

to exceed 0.1 mm. Where they are in excess of this size, a new cutting edge

should be selected. Replace cutter accordingly

8. Calibration

No

calibration of this instrument is required, inspect for wear see para 6.0.

9. Further

Information

For more

information regarding this product, spares, accessories etc. or if you would

like a catalogue listing our full range of products, please contact your local

agent or BEVS Industrial Ltd .

10. Order

Information

BEVS2202/1C Cross Hatch Cutter (1MM 6Blades)

BEVS2202/2C Cross Hatch Cutter (1MM 11Blades)

BEVS2202/3C Cross Hatch Cutter (1.5MM 6Blades)

BEVS2202/4C Cross Hatch Cutter (2MM 6Blades)

BEVS2202/6C Cross Hatch Cutter (3MM 6Blades)

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | T/T | Shipping time | Negotiable |

- President

- Owen Chan

- Address

- Rm1818, Dongcheng Int’l Plaza,No.3, Huangpu East Road,Guangzhou City, China

- Product Category

- Electronic Measuring Instruments,Measuring & Analysing Instrument,Testing Equipment

- Year Established

- 2004

- Company introduction

-

BEVS Industrial Co.,Ltd. is a leading manufacturer that specializes in coatings, ink, painting, resin testing instruments and laboratory whole solution.We offer the complete and unique products in this field to meet customer's challenging demands of today and tomorrow, the products are complied with the standards of ISO, ASTM, DIN, BS, EN etc.With strong supports and hard work by lots of end-users and worldwide agents, BEVS become more and more famous in the world and provides more competitive values for our customers.

- Main Markets

-

Australia

Australia

Japan

Japan

Viet Nam

Viet Nam

- Main Product

Related Products

Elevator Speedometer (Statistical Type) ES-2100B

TEST ICE

Hardness Tester (Rockwell Type Brinell Type)

Single Linear type 350Ω Cas Strain Gauge

Truck Weighing Load Cell

China

China