Laser Welding Machine_LWI V Flexx Workstation T-BASEV2

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Germany

- Brand name

- Vision Lasertechnik GmbH

- Payment Terms

- T/T

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Industry Laser Equipment & Parts

Vision Industries Korea LLC.

- Verified Certificate

-

10

| Product name | Laser Welding Machine_LWI V Flexx Workstation T-BASEV2 | Certification | - |

|---|---|---|---|

| Category | Industry Laser Equipment & Parts | Ingredients | - |

| Keyword | laser welder , laser welding machine , laser welding system , laser welding equipment | Unit Size | 1290.0 * 820.0 * 710.0 mm |

| Brand name | Vision Lasertechnik GmbH | Unit Weigh | 100 kg |

| origin | Germany | Stock | - |

| Supply type | - | HS code | 851580 |

Product Information

Your beneft: increased productivity and replicable welding quality!

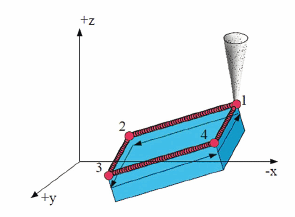

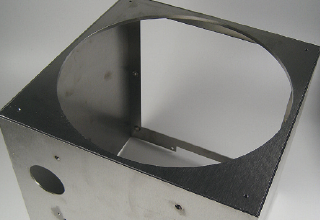

The Workstation T-Base V2 expands your FLEXX, turning it into a

compact, open welding station with a digitally-controlled three-

axis work table and a separate height-adjustable laser head.

With a unique control concept, you can extend manual welding

via a precise motion control with sophisticated automatic and

program functions.

Your beneft: increased productivity and replicable welding quality!

Highlights

Precise work table

The XY cross table, with its stable precision linear slide, screw drive and high-resolution stepper motor, provides the basis for exact positioning and high repeat accuracy. Your work piece can be accurately and flexibly set on the plainmilled aluminium slot profile slab.

Stable stamp axis

Thanks to its elaborate linear slide on four large stainless steel shafts and precision cylinder sleeve, the precise steering of high loads is guaranteed. The high-resolution screw drive with its powerful stepper motor provides both exact positioning and high processing speeds.

CAN-Step: The intelligent axis control

Precisely controls axis movements. This extends manual welding by its sophisticated automatic and programable functions. Touchscreen and Joystick terminals directly in your workspace provide a unique, simple control concept. Thanks to the completely integrated hardware, a separate computer is not needed.

PDS – Pulse Distance Synchronization

Enables the handling of complicated geometries in four axis without complex programming. A small number of support points are hit once on the contour of the work piece in advance. The user can subsequently move the programmed welding line forward and backward using the joystick and can also shift its position by offsetting the start point.

„Teach in“ programming

Enables the handling of complicated geometries in four axis without complex programming. A small number of support points are hit once on the contour of the work piece in advance. The user can subsequently move the programmed welding line forward and backward using the joystick and can also shift its position by offsetting the start point.

PCD – 3 Point Cycle Definition

You can process circular type contours by using the PCD function with the XY axis. The circular path is precisely defined through the teaching of only three support points. You do not need to know the center or the diameter; the position on the work piece is optional. You can move along the programmed course either forward or backward by using the joystick.

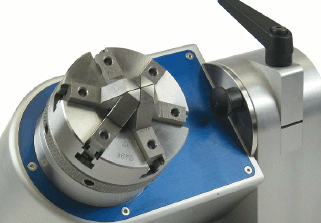

Combinable with a rotating device

Specially developed turning units increase the user value of your workstation. They incorporate all functions of CAN-Step control, available at the touch of a button, including pulse synchronization and „Teach in“ programming. Additional features: • Swivel-mounted • Free implementation up to Ø40 mm • different chuck types, chucking range up to Ø 160 mm.

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | T/T | Shipping time | Negotiable |

- President

- Ingeun Choi

- Address

- 22-1, Siheung-daero 935beon-gil, Siheung-si, Gyeonggi-do 14956, Korea

- Product Category

- Industry Laser Equipment & Parts

- Company introduction

-

Global Laser welding & marking machines

- Main Markets

-

Brazil

Brazil

Thailand

Thailand

Viet Nam

Viet Nam

- Main Product

South Korea

South Korea