TRI CUONG INDUSTRIAL Co., Ltd

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Viet Nam

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Other Machinery & Industry Equipment

THE ASSISTANCE CENTRE FOR SME, NORTH of VIETNAM.

- Verified Certificate

-

9

| Product name | TRI CUONG INDUSTRIAL Co., Ltd | Certification | - |

|---|---|---|---|

| Category | Other Machinery & Industry Equipment | Ingredients | - |

| Keyword | cnc milling machine , conveyor system , manufacturing & processing machinery | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | Viet Nam | Stock | - |

| Supply type | - | HS code | - |

Product Information

General Introduction:

Established in 2006 with slogan “Create

your values”, Tri Cuong Industrial (TCI) Co., Ltd has been becoming a leader in

designing and manufacturing various types of precision parts, factory equipment

and custom automation in Vietnam. Located in Hanoi capital with 2000 square

meters and 120 qualified employees, our factories are equipped with state of

the art CNC machinery mainly from Japan. TCI is ISO 9001-2008 and ISO 14001

certificated company and service in a variety industry of automotive,

electronic, semiconductor, medical and other industries. We offer full service

of consultancy, design, manufacturing, installation and maintenance. To the end

of 2014, we have well installed more than 800 projects for Foreign Direct

Investment (FDI) companies in Vietnam and exported products to Japan &

Europe.

Our Strategy:

Sustain profitable growth by providing a

variety of automation and technical services that meet or exceed our customers'

requirements. TCI is totally committed to customers’ satisfaction and

profitable operations through continual improvement and employee ownership..

Our Mission:

Our mission is to start with customer's

needs and end with customer's satisfaction by ensuring four factors: Quality,

Cost, Delivery, and Service. We also create a safe, good work environment,

ensure the right and benefit of our employees as well as carry out society

mission.

Through this exhibition, we proudly present to you these products:

1,CNC milling and turning parts [Product detail image 1-2]

Product Description

CNC machining:

·

We are a professional manufacturer on

precision machining parts with more than 10 years experience

·

A state of the art precision 3/4/5

axis CNC machines meet your delivery requirements

·

Precision measuring equipments

Mitutoyo 3D Measuring Machines (CMM) ensure the quality of products.

·

Material: Stainless

steel/Steel/Brass/Copper/Aluminum

Product Specification

|

CNC Milling |

Machining

up to 800Y*600X*500Z, weight 500kg |

|

CNC

Turning |

Diameter

up to 300mm*600mm, weight 250kg |

|

Wire EDMs |

Machining

up to 300Y*300X |

|

Grinding |

Cylindrical

grinding up to 200*1200 |

|

Our

surface grinders can grind up to 460*300*300 |

|

|

Material |

Aluminum

Alloy: 5052 / 6061 / 2017 / 7075 / etc. |

|

Brass

Alloy:3602 / 2604 / H59 / H62 / etc. |

|

|

Stainless

Steel Alloy:303 / 304 / 316 / 412 / etc. |

|

|

Steel Alloy:Carbon

Steel / Die Steel / etc. |

|

|

Inspection |

Our

Mitutoyo Tool Microscope can measure up to 300mmX x 400mmY x 300mmZ |

|

Processing equipments |

CNC

machining center, grinding machine, milling machine, drilling machine,

horizontal milling machine, chamfering machine, CNC cutting machine etc. |

|

Surface

finishes |

anodizing,hard

anodizing,sand blasted,annealing,polishing, |

|

heat

treatment;zinc-plated,chromed plated |

|

|

Cad Cam |

Solid

Works, AutoCAD(DXF,DWG), PDF,TIF etc. |

|

Application |

Automation

machine, medical device, industrial machine, automobile, electric appliance,

and other industries |

2, Customized machine & automation [Product detail image 3-4]

Product Description

With more than 9

YEARS EXPERIENCE in AUTOMATION. TCI has a group of 20 engineers with fully

capable of taking a concept to reality, be it a fully integrated system or a

prototype. We pride ourselves on our engineering expertise and utilize cutting

edge technologies to drive our success. Automatic machine designed and built by

TCI was used in the construction industry, automotive, motorcycle, electronics

and telecommunications, healthcare, food and consumption with high

productivity, operating safety and stability. TCI provides consulting services,

design, fabrication, installation and delivery to the clients. All the products

are designed in 3D, optimal motion simulation before manufacturing on CNC

machines and Assembly in clean rooms, ensure accuracy, reliable operation and

reasonable price. With the desire to bring value to customers, TCI continually

invest new equipment, training and implement philosophy of high

quality-reasonable price-perfect service.

Product Specification

All the machine parts are manufactured on high-precision

CNC machines.

-Standard components of electrical control, cylinder, motor are imported from G7 countries

- Sub components are assembled in a clean room at the TCI

-The machine has the function of determining error, an

emergency stop, safety warning and

protection

-Warranty 1 year after installation of the trials at

customer plant

- Periodic maintenance and technology transfer

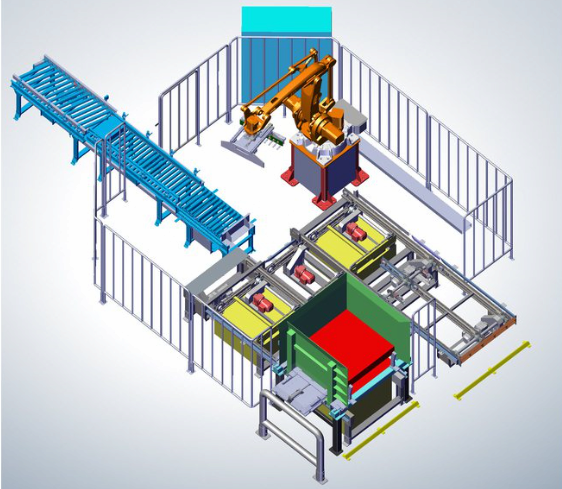

3, Conveyor and material handling system [Product detail image 5-6]

Product Description

TCI Conveyors are

built to order based on our customer’s specifications. This approach allows us

to provide equipment that is exactly as needed with short lead times. Leading

the conveyor industry in built to order equipment, TCI’s wide range of sizes

and options allow us to offer as our standard product what our competitors

would consider special equipment and many of these conveyor models. Our

material handling equipment is divided into the following product classes:

Gravity Conveyors, Belt Conveyors, Chain Driven Conveyors, Belt Driven Roller Conveyors,

Transfers, and Accessories.

Product Specification

Our conveyor can

transfer goods until the next person or machine, sort or merge them

intelligently, and can facilitate a number of functions that add value to the

order fulfilment process, such as packing and weighing. Conveyors can transport

goods horizontally, vertically, around corners, and handle inclines and

declines. Usually they are electrically driven, but often gravity can play a

crucial role as well.

Enjoy 'Vietnam Special' Online Exhibition on tradeKorea.com

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Le Manh Hung

- Address

- 10th floor, D25, MPI Building, Ton That Thuyet, Cau Giay Dist, Hanoi Vietnam

- Year Established

- 2004

- Company introduction

-

1. GENERAL INFORMATION

Logo of TAC HANOI

(1) Name, address and telephone number of the organization

The Assistance Center for SMEs - North Vietnam (TAC-HANOI)

Agency for Enterprise Development (AED) - Ministry of Planning and Investment (MPI)

Address: 10th Floor, LotD25, MPI Building, Ton That Thuyet street, Cau Giay district, Hanoi, Vietnam

Telephone number: (+84) 04 858 793 21; Fax number: (+84) 04 730 556 86

(2) Function and major activities of the organization: (* preferably with an organizational structure chart)

Organizational structure of TAC HANOI

TAC- HANOI functioned to conduct and implement policies and programs on SMEs support in the north of Vietnam since its establishment in 2004. It is mandated including but not limited to:

* Conduct training programs to improve business management capacity for SMEs.

* Provide consultancy and to act as focal point in collecting, providing and disseminating information to SMEs on technology, technique, manufacturing management and other business development services (BDS).

* Carry out and promote business linkage.

* Implement some pilot projects on direct support to SMEs as designated with information dissemination on promotion.

* Incubation for business start-up.

(3) Annual budget of the organization:

Approximately equivalent to 50,000 USD including staff salary and office recurring expenses

- Main Markets

-

Viet Nam

Viet Nam

- Main Product

Related Products

Date Pin (Date Core)

12V KIOSK THERMAL Printer Mechanism(Module) and Board 2inch

New High Pressure Exhaust Fan(30cm)

Korean children's clothing chichikaka brand

AIRLESS PUMP- YL 731