Black Siicon Carbide for steel making

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Payment Terms

- L/C,T/T

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Refractory

HY TRADING CORPORATION

- Verified Certificate

-

10

| Product name | Black Siicon Carbide for steel making | Certification | - |

|---|---|---|---|

| Category | Refractory | Ingredients | - |

| Keyword | refractory , silicon carbide , silicon carbide black , silicon carbide deoxidizer | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | China | Stock | - |

| Supply type | - | HS code | 284920 |

Product Information

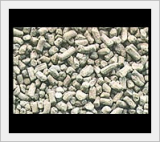

Black Silicon Carbide(SiC)

Port of Tianjin

Product Description:

Black silicon carbide is mainly made of quartz sand,petroleum coke,smelted by above

2500 in the electric furnace , the hardness is between corundum and diamond,the hardness

is superior to corundum, it has the function of conductivity and thermal conductivity.

It is suitable to process metals and non-metallic materials. Such as gray cast iron,non-ferrous

metals, stone,leather,rubber and so on .It also widely used in refractories,metallurgical

Additives.

Main Application:

1 .Abrasive Material:

Black Silicon Carbide is suitable to grinding and cutting cast iron non-ferrous metal, leather ,rubber , wood ,plastic etc. It also can be made top grade refractories material ,silicon carbide has the characteristics of good stability ,equal particle size,high grinding and cutting and good wear resistance. It is mainly used to made sandpaper, abrasive belt, Whetstone, grinding blocks, grinding head, grinding paste and photovoltaic products

2 . Metallurgical and Chemical industry:

It is mainly used as deoxidizer in steelmaking process,both used as the main raw material of the silicon resin industry. Silicon carbide deoxidizer is a new kind of strong compound deoxidizer replace the traditional silica fume,toner deoxidation,it is more stable and deoxy effect , Improved the quality of the steel ,reduce the consumption and environmental pollution and so on .

3 . Wear-resistant, fire-resistant and corrosion-resistant materials

The use of silicon carbide with corrosion-resistant, high temperature strength, good thermal conductivity, impact resistance and other characteristics of silicon carbide on the one hand can be used for a variety of smelting furnace lining, the component of high-temperature furnaces, silicon carbide plate, silicon carbide crucible.

The other hand, can be used in non-ferrous metal smelting industry, high-temperature indirect heating materials, such as Vertical Retort furnace, distillation furnace tower plate, aluminum cell, copper melting furnace lining, thermocouple protection tubes; for the production of wear-resistant, resistant corrosion, high temperature silicon carbide ceramic material

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | L/C,T/T | Shipping time | Negotiable |

- President

- LI XI PENG

- Product Category

- Silica

- Company introduction

-

Haicheng Shengyueruiheng Mining Industry Co., Ltd. is an integrated company engaged in mining, beneficiation, processing and trading. Our company was founded in 2010 and headquartered in Haicheng City, Liaoning Province, which is known as "The Home of Talc" and "China Magnesium Capital". Our international trading company located in Bayuquan City, Liaoning Province has 110 employees, including 10 professional and technical personnel, with existing fixed assets of more than 50 million Yuan.

Our company has a large range of products including talc, magnesium stone, fluorite and feldspar. Our production equipment is the most advanced in domestic and foreign countries. We are specialized in the manufacture and export of talcum powder, light burned magnesium powder, magnesium oxide white balls, dead burned magnesite, fluorite, quartz sand, brucite, potassium feldspar, sodium feldspar, silicon carbide, ferroalloy and other products.

With sincere attitude, advanced equipment, consummate technologies, excellent products and first-class services, our company has attracted a large number of domestic and international customers. 90 percent of our products are exported to Southeast Asia, Europe and the United States. Emphasizing quality, constructing reputation and observing contracts, we have won consistent praise from our domestic and foreign customers

We will focus on improving the quality and grade of existing products, and researching and developing new technologies and products for domestic and foreign customers with our best services.

- Main Markets

-

Japan

Japan

North Korea

North Korea

- Main Product

China

China