Foam Concrete Brick Production Line

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

Shield Machinery Manufacturing Factory

- Verified Certificate

-

9

| Product name | Foam Concrete Brick Production Line | Certification | - |

|---|---|---|---|

| Category | Construction Material Making Machinery | Ingredients | - |

| Keyword | foam concrete brick , foam concrete brick equipment , clc block machinery , non-autoclaved aerated concrete | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | China | Stock | - |

| Supply type | - | HS code | - |

Product Information

Foam Concrete Brick Production Line

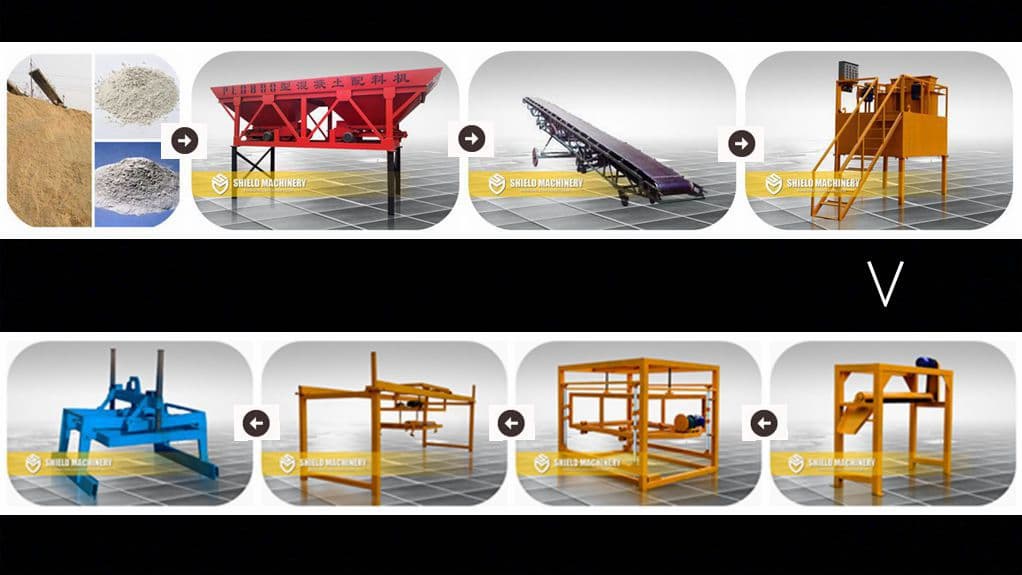

Our factory produces foam concrete brick machinery, all the machines combines a production line. The production line includes electronic batching machine, band conveyor, foam mixer, ferry car for holding mold, stacking machine, parallel cutting machine, cutting machine, track car, push car, mold. The production line of foam concrete brick is highly automatic, you can control the machines only by pushing several buttons. In addition, there are many other advantages. The detailed information is as below:

1.Feeding mode: through electronic batching machine, the raw materials, water and foam agent are put into the foam mixer on a fixed proportion. Thus the working machines flow smoothly, and also save the time.

2.Stirring mode: the stand mixer makes the raw materials and water stirring well.

3.Foaming mode: aluminum powder is used to make the foam. So the foaming is stable and even.

4.Producing mode: the production line is highly-automatic, controlled by PLC. So the efficiency is quite high.

5.Cutting mode: we use saw blade to cut the blocks. With this kind of cutting machine, the cutting section is not limited to time. What’s more, this kind of cutting machine makes the block looking attractive.

6.Mold: the wall and the bottom of the mold can be separated. Cooperated with the ferry car, you can unload the mold automatically. And you can also save the cost by buying more bottom and less wall.

7.Output: the production line of foam concrete brick is highly automatic, only 3 to 4 workers can control the whole production line. And the output of this production line is 200 cubic meter per day.

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Jiao Hongwu

- Address

- xiaokang road, gongyi city, henan province, Chine

- Product Category

- Construction Material Making Machinery

- Year Established

- 1984

- No. of Total Employees

- 51-100

- Company introduction

-

Shield Machinery is a foam concrete brick equipment manufacturing factory. Foam concrete brick, also called CLC block, cellular lightweight concrete block, and non-autoclaved aerated concrete block, is a new wall material. It has features of light weight, high strength, heat preservation, heat insulation, fire prevention, anti-seismic, sound insulation, anti-permeability and good machinability etc.

- Main Product

Related Products

Flap disc

Earth moving spare parts made in S Korea

GS Flanged Riser Pipes for Submersible Pumps

Foam concrete blocks plant

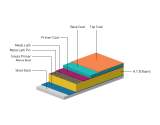

A-60 CLASS DECK COVERING, YATOMIX A60H

China

China