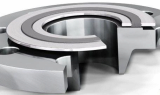

Lip seal for rotary sealing system

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- South Korea

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- mechanical seal, oilseal, seal kit/o-ring, seal unit

- Category

- Seals

Sealink Corp

- Verified Certificate

-

9

| Product name | Lip seal for rotary sealing system | Certification | - |

|---|---|---|---|

| Category | Seals | Ingredients | - |

| Keyword | mechanical seal , oilseal , seal kit/o-ring , seal unit | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | South Korea | Stock | - |

| Supply type | - | HS code | - |

Product Information

The new generation of Sealink rotary shaft lipseals were especially developed for useunder difficult and extreme conditions.

The superior properties of PTFE as lip material combined with a corrosion resistant stainless steel housing provide the particular advantages of these rotary shaft lip seals.

Advantages and applications:

Temperature range from -70? bis +260?

Lowest friction and power draw

Long seal life because of wear resistant lip materials

Almost universal chemical resistance (depending on lip material)

Suitable for dry running and poorly lubricated conditions

High shaft speed up to 36 m/s

Exchangeable with standard lip seals according to DIN 3760

For food or pharmaceutical industry

For compressor and rotary sealing system

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Hee Jang, Rhee

- Address

- #704(Gasan-dong, 12cha, Daerung Technotown) 14, Gasandigital 2-ro, Keumcheon-gu Seoul, Korea

- Product Category

- Seals

- Year Established

- 2014

- No. of Total Employees

- 1-50

- Company introduction

-

Sealink is one of the world’s leading companies specialized in developing,

manufacturing and marketing of vacuum and pressure rotary sealing solutions.

These solutions include rotary feedthroughs, linear feedthroughs, double acting – rotary & linear motion – feedthroughs and multiple passage rotary unions for high vacuum or high pressure process lines. These will simplify and further improve the conventional magnetic and mechanical sealing units.

We offer customized sealing units to meet customer’s application requirements as well as standard sealing units for a wide range of industries including semiconductor, LCD and OLED industries, pharmaceutical and chemical processing Industries, etc.

All our products are manufactured under strict quality control and in ISO 9001 / ISO 14001 certified manufacturing facility in Korea and we will always continue to improve our present products and technology for further customer satisfaction.

<Mechanical Seal VS Magentic Seal VS Sealink Seal >

Spec

Mechanical Seal

Magnetic seal

Sealink Seal

Vacuum

Impossible

possible

possible

Pressure

possible

Impossible

possible

Chemical

possible Impossible possible Lubricant

Required

Not Required

Not Required

- Main Product

Related Products

Knitted wire mesh Gaskets Seals

Seal of transmission components

Sell SPIRAL WOUND GASKET with non asbestos filler

Mechanical Seals, Dual Cartridge - CTDM

Bearing seal

South Korea

South Korea