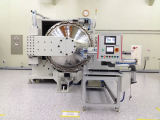

Temperature Humidity Chamber

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- South Korea

- Brand name

- IREA TECH

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- temperature & humidity chamber

IREA TECH

- Verified Certificate

-

11

| Product name | Temperature Humidity Chamber | Certification | - |

|---|---|---|---|

| Category |

Chemical Machinery Equipment

Temperature Instruments |

Ingredients | - |

| Keyword | temperature & humidity chamber | Unit Size | - |

| Brand name | IREA TECH | Unit Weigh | - |

| origin | South Korea | Stock | - |

| Supply type | - | HS code | - |

Product Information

Characteristics

Gorgeous exterior for safety

Its all-round appearance for safety against collision. Its smooth door locking device is parallel including its handle.

With ex-model color monitor(5.7” color touch interface) applied, its setting and progressing lists are shown.

Compared to sealed exterior products with SUS quality, it has stronger characteristic to prevent oxidation which always stays clean.

It’s a stable and reliable thermo-hygrostat series

MRU series is used in testing relatively smaller elements such as components, various types of industries ex. Electric/electronic components, LCD, RF communication, or notebook, etc.)

Control panel, Electrical control system, insulating blocks, air circulating parts, and heating and cooling parts are module products. Chambers are precisely divided into four types including standard size and ten other standard sizes.

Insulation ceramic wool and polyurethane are double-structured, which is outstanding in insulating effects in high & low temperature.

Observation window provides sufficiently wide view and considering glass breakage, it consists of quadruple view glasses and one extra protective window.

Heating lines are installed inside the door which suppresses humidity to occur in the door. (CE type)

Cartridge type of water tank supplies water for clean and convenient management.

It applied our own developed controller(NU-7000) for this thermo-hygromat.

Measuring method

Put products in the chamber and shift them repeatedly high and low temperature sections. At this moment, measure changes of that product. Measure its temperature and displacement caused by temperature changes, and strain measurements. When it is an electric board, measure its resistance.

Use a chamber that controls temperature and humidity changes when measuring state changes of the product.

A sensor detecting changes of the product should be attached to it, apart from chamber control.

Types of sensors: Acceleration sensor, LVDT(displacement), Torque sensor, Strain Gage(stress measurement), Load cell(Weight), Thermocouple(Temperature), dew point instrument(dew point temperature measurement), voltage probe, current probe.

User must choose a sensor that fits the quantity he wants to measure.

Professional consultation is required when choosing methods, types or attaching places of the sensor is because they are different depending upon their type, forms, quality, and strength.

Temperature/Humidity Control

1. Sirocco fan minimizes the dead zone in the chamber for outstanding temperature and humidity distribution and also provides more of airflow.

2. Temperature and humidity distribution in the wide space of the chamber are equal.

From interior part of the chamber to one tenths of the chamber the equal distribution is shown.

3. It expands controlling area from low-temp & humidity by minutely controlling the operation of the freezer and the heater for humidification and dehumidification.

4. Specially-designed dehumidifier accurately guarantees its control low humidity(7% R.H) and low temperature of 5c for its reliability test.

Self-diagnosing its failed parts

A perfect design to minimize errors or failures.

When you activate the safety device of the chamber, all parts of the product will be displayed when alarmed. It shows on the screen the reason and the location of the alarm occurrence as well as its solution.

It guarantees user’s safety the most as power turns on by confirming limit control when over temp. was happened.

Electrical circuit and water supplying circuit for humidification are separated.

Convenience for user

When you activate the safety device of the chamber, all parts of the product will be displayed as it’s alarmed. It shows on the screen the reason and the location of the alarm occurrence as well as its solution.

Controller

It’s easily controllable.

It’s easy to control and program because it precisely displays the information of the chamber from 5.7” RGBX240, color LCD touch screen type, TH-500.

By using touch type inserting method and easy-to-follow commands on the screen, even inexperienced users will be able to operate perfectly and accurately the controller.

Maximum 120 programs are repeatedly set in total 999 steps and cycles.

*Expanding ability

-Computer interface

1. It is well used when managing the machine with a small number of people, by using RS 485 communication about 16 machines are controllable by one computer. You may control maximum 32 of them by controlling the screen. Through the program(option)supplied by our firm, it is convenient for collecting and storing the testing data by remote control of the machine.

2. With SMS program, user will be able to receive data messages or error occurrences by text messages when he is away from the machine. This makes the management very effective.

-Software

High-speed Interface(maximum 38.4kbps) by RS-485(ELARS485 standard), other parameters and program patterns are set in the PC. PC-link, Ladder communication, cooperative operation, and four types of protocol.

A test run that does not require defrosting process

A system that suppresses the growth of frost which continues to repeatedly operate without its process.

Frost usually appears on the evaporating tube for dehumidification of the cooling device located on the back of the machine. It does not give any damages in air circulation. When it reaches its certain thickness, with energy from circulating air on the surface of moisture and its heat-absorbing energy transferred from a dehumidifying-evaporating tube will be parallel which will stop its growth. Therefore, the temperature of the chamber will be consistently stable and there is no need for users to remove moisture regularly during the operation.

By using electric humidity sensor, user will be able to accurately control humidity in a condition from -40C/-70c up to 150C.

-Plastic molding design

1. It was manufactured to prevent any possible defects by lessening difference in temperature no more than 5 C between inside and outside.

2. It minimizes risks influenced by outer temperature.

3. It was designed not to cause error due to high-temperature heating around the controller.

4. It cuts off any temperature changes around the tank so that the tank could always supply cold water. The machine emits heat generated by a condenser on the top to the right which makes its distributional space narrow. It’s also easy to make connections with the Duct. (Option.) For a complete block between the interior and exterior parts of the chamber it was one-pieced polycarbonate mold structured. Vicelock type action door connected with a handle and silicon gasket make a perfect enclosure.

-Consistent temperature distribution

By using a tangent flow fan it circulates air in the most appropriate speed which maintains its consistent temperature and humidity in the chamber. When you open the door, heater and the fan will eventually stop air in the chamber to contact outside.

Motor and the body are integral which prevents different pressure occurrence during air circulation which collects air flow from vortex generation. Eventually, it will soon reach afar to make air circulation smooth and make the best out of temperature and humidity distribution without less noise.

The control method of refrigerant flow quantity

Temperature 25c/humidity 60%/1 hour(maintaining time)

Temperature 40c/humidity 75%/30 minutes(temperature/humidity rising time)

Temperature 40c/humidity 75%/1 hour(maintaining time)

Temperature 85c/humidity 85%/40 minutes(temperature/humidity rising time)

Temperature 85c/humidity 85%/1 hour(maintaining time)

Temperature -40c/2 hours(temperature decreasing time)

Temperature -40c/1 hour(maintaining time)

A graph(changes in humidity) on Temperature 25C/humidity 60%

A graph(changes in humidity) on temperature 40c/humidity 75%

A graph(changes in humidity) on temperature 85c/humidity 85%

Defrosted circuit

-The chamber automatically finds the state of moisture in the evaporating tube when operated under 0c during its repeated operation and defrost.

1. liquid nitrogen or carbon dioxide

2. For the rapid decrease in temperature in the chamber, liquid nitrogen or carbon dioxide cylinder is connected to the chamber.

- Product Info Attached File

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- SIHYEOK WOO

- Address

- #105(ISA-DONG), 166 BEON-GIL, ISA ROAD, DONG-GU, DAEJEON METROPOLITAN CITY, KOREA

- Product Category

- Chemical Machinery Equipment,Chemical Storage Equipment,Drying Equipment,Pressure Vessels

- Year Established

- 2007

- No. of Total Employees

- 1-50

- Company introduction

-

We, IREA TECH, are dedicated to creating reliable machineries mainly focusing on all of our products fitting our customers’ requirements. Especially due to our strong partnerships with firms such as Samsung, LG, or Hanwha, we were able to continually raise our level of performance, quality, and elegance since our establishment in 2007. We boldly guarantee you that our software, hardware, contents, delivery systems, and post-sales service will be completely satisfactory. We also embrace our customers sharing their perspectives, ideas, and encouragement because they challenge us to get continue to better in what we do. We continuously look forward to expanding our business partnership and enhancing our high-technique performance and quality with customers abroad.

- Main Markets

-

Canada

Canada

China

China

France

France

U. Kingdom

U. Kingdom

U.S.A

U.S.A

- Main Product

Related Products

SIC Muffle Furnace

Refrigerated Heating Bath Circulators - P

U-Prime (Environmental monitoring device)

Muffle Furnace

Temperature Humidity Recorder

South Korea

South Korea