Automated lines polystyrene concrete blocks

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Russia

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

Siberian Constructing Technologies LLC

- Verified Certificate

-

10

| Product name | Automated lines polystyrene concrete blocks | Certification | - |

|---|---|---|---|

| Category | Construction Material Making Machinery | Ingredients | - |

| Keyword | cutting machine , polystyrene concrete , automated lines , polystyrene blocks | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | Russia | Stock | - |

| Supply type | - | HS code | - |

Product Information

The company Siberian Construction Technologies designs and completes automated factories for polystyrene concrete production. In the design of the lines it is possible to provide delivery of commercial polystyrene concrete mixtures followed by shipment to ready mix trucks. The main conception of these technological lines development is control of quality grade and parameters stability of the products at the stage of designing of processing methods and component analysis of polystyrene concrete mixture in view of their interaction extent, and also development of automation system and quality control at all stages of manufacturing.

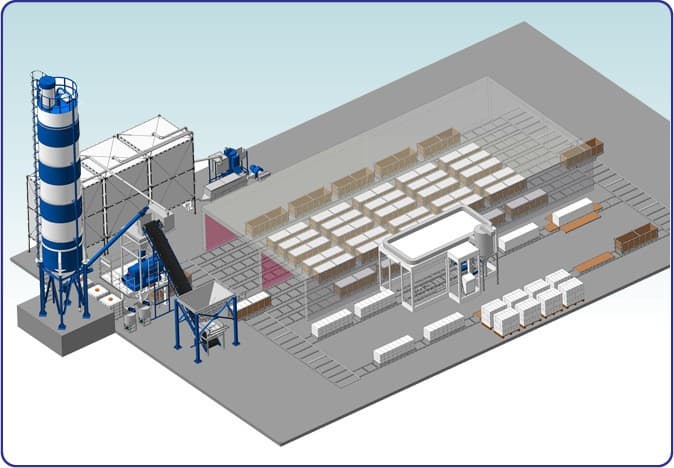

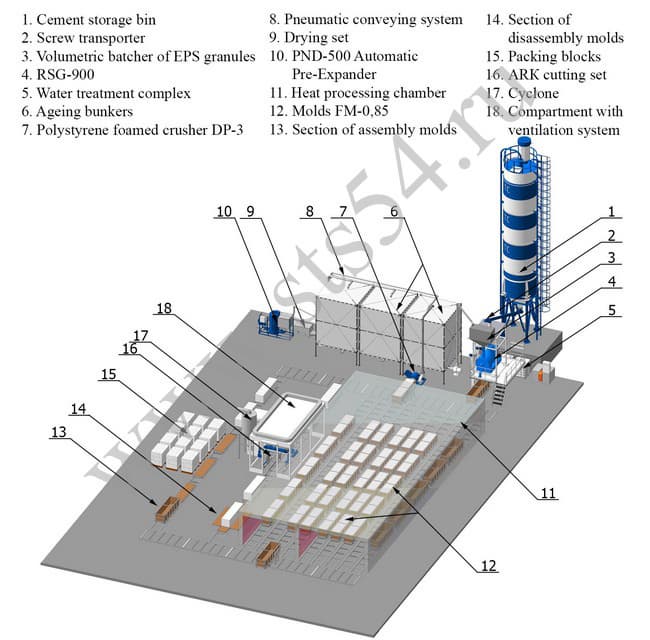

Factory includes:

- Sector of storage, preparation and feeding of raw materials;

- Sector of foaming;

- Mixing sector;

- Sector of moulding;

- Thermal treatment sector;

- Sector of polystyrene concrete mass sawing;

- Storage area for finished product.

Automation of technological processes of polystyrene concrete products manufacturing allows not only reduce production costs but also significantly raise stability of its basic properties minimizing the human factor, especially in the process of raw components batching and polystyrene concrete mass sawing.

Advantages:

Automation of working operations control processes. Electronic control systems of raw materials feed and batching in the mixing sector are used in these production lines. One operator controls the mixing sector functioning. Also only one operator controls functioning of the cutting set in the mass sawing sector.

Permanence of batching. Consumable materials are put to the weigh hopper with strain sensors and balance controller, which allows getting precision weighing. Constant volume of polystyrene granules is provided with the sensor of the volumetric batcher.

High quality of mixture stirring. Stirring gear consists of two oppositely directed screws. This provides full and high-quality stirring of polystyrene mixture.

High productivity. Provided by the automated system of feeding and batching of raw materials, as well as speed of loading the mixer with water and raw components. The high-capacity cutting set provides high speed of sawing of mass into blocks of given sizes is provided.

Quality of products. The products manufactured by our numerous clients are certified. We invite you to get to know our products and confirm its advantages

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Artem Kistin

- Address

- 630001 Russia, Novosibirsk. Zhukovskogo 102, office 408

- Product Category

- Construction Material Making Machinery

- Year Established

- 2000

- No. of Total Employees

- 51-100

- Company introduction

-

«Siberian Constructing Technologies» is a well-known Russian company, founded in 2000. The company designs technologies and makes certified equipment for production of modern constructing materials both for small-scale and middle-scale business.

Our mission is to implicate resource-saving technologies of production of constructing materials. Resource-saving technologies are based on the usage of secondary raw materials including industrial wastes which chemical and mineral composition is the same or even better than the composition of traditionally used materials. Implementation of resource-saving technologies allows to decrease cost price. Testing of technologies is conducted by our company's specialists at the laboratory, following by implementation of technologies at our automated mill/factory for production of units from non-autoclave foamed concrete, aerated concrete, as well as from polystyrene concrete.

- Main Markets

-

Hong Kong(China)

Hong Kong(China)

India

India

Russia

Russia

- Main Product

Related Products

A-60 CLASS DECK COVERING, YATOMIX A60H

Flap disc

Block Making Machine Mould

Flap wheel

Unideco Luxury Vinyl Tile New Design 2016