Foam concrete blocks plant

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Russia

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

Siberian Constructing Technologies LLC

- Verified Certificate

-

10

| Product name | Foam concrete blocks plant | Certification | - |

|---|---|---|---|

| Category | Construction Material Making Machinery | Ingredients | - |

| Keyword | aac blocks plant , foam concrete , automated cutting machine , foam concrete line | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | Russia | Stock | - |

| Supply type | - | HS code | - |

Product Information

The non-autoclave foamed concrete units are much in demand, that is why producers are focused on designing modern automated mini-mills and developing efficiency of existent equipment for foamed concrete production. Production of high quality competitive products in accordance with customers’ demands and constructing standards make producers to develop technologies and equipment, and to increase automation of all technological processes of production.

Following modern market demands «Siberian Constructing Technologies» LLC designs and completes automated foamed concrete mills. Main conception of these technological lines is quality management at all stages of production process: from the project stage where stability of products characteristics depends on chosen technologies and component analysis to the final stage of production.

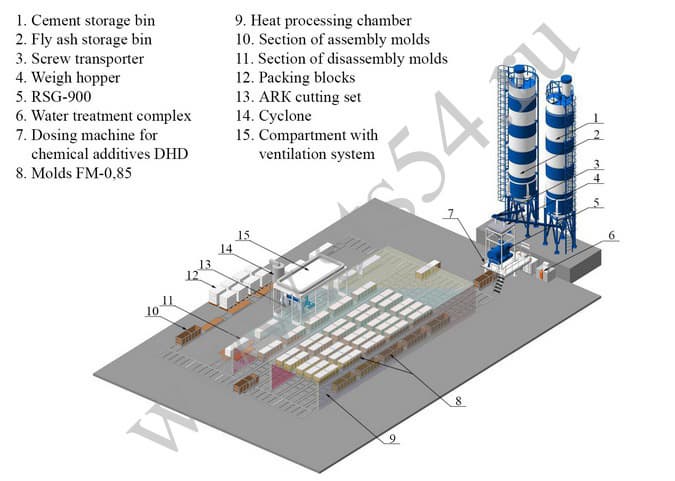

Sections of foamed concrete mill:

· Section of receiving, utilization and storage of raw materials;

· Mixing section;

· Forming section;

· Thermal treatment section;

· Sawing section;

· Produced goods' storage section.

Automation of technological processes in non-autoclave foamed concrete production enables to decrease prime cost of products as well as to increase stability of products’ characteristics due to minimization of human factor especially in the process of proportioning of raw materials.

Advantages of the automated line:

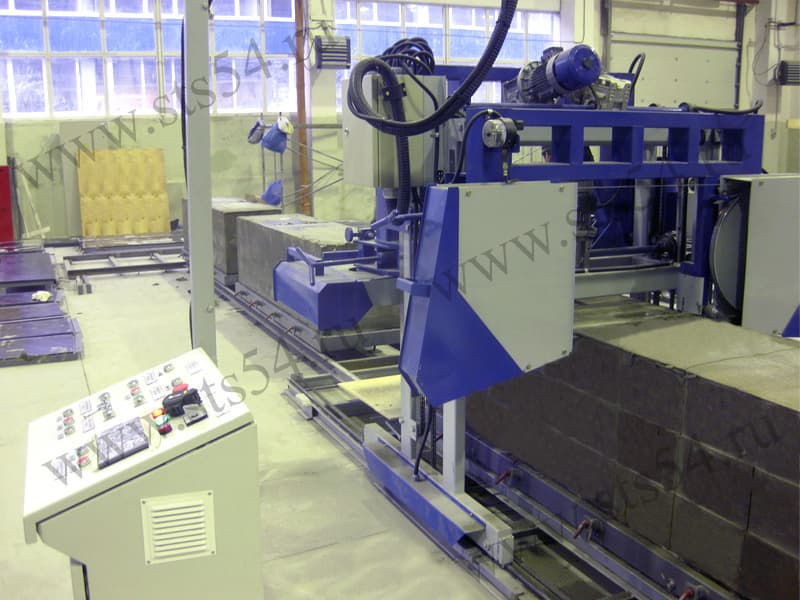

Automation of processes of technological operations. In production lines, electronic control systems used feeding and dosing of raw materials to the mixing area. The work of the mixing section is managed by one operator. The work of the cutting section is managed also by one operator.

Stability of batching. Starting materials go to a weigh-batcher which has strain indicators and a weight controller. This ensures precise weighting.

High quality of mixing. Mixing mechanism consists of two screws adjusted in opposite directions. This allows foam and mortar to be mixed thoroughly.

High level of capacity is reached by automated feeding and batching of raw materials as well as by the particular characteristic of cutting complex – a frame has two cutting heads for vertical and horizontal cutting of foam concrete. One pass ensures two cuts in different planes.

Quality of produced goods. Using our equipment customers get products which have been certified. Welcome to discover and to try our products, its’ advantages and disadvantages.

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Artem Kistin

- Address

- 630001 Russia, Novosibirsk. Zhukovskogo 102, office 408

- Product Category

- Construction Material Making Machinery

- Year Established

- 2000

- No. of Total Employees

- 51-100

- Company introduction

-

«Siberian Constructing Technologies» is a well-known Russian company, founded in 2000. The company designs technologies and makes certified equipment for production of modern constructing materials both for small-scale and middle-scale business.

Our mission is to implicate resource-saving technologies of production of constructing materials. Resource-saving technologies are based on the usage of secondary raw materials including industrial wastes which chemical and mineral composition is the same or even better than the composition of traditionally used materials. Implementation of resource-saving technologies allows to decrease cost price. Testing of technologies is conducted by our company's specialists at the laboratory, following by implementation of technologies at our automated mill/factory for production of units from non-autoclave foamed concrete, aerated concrete, as well as from polystyrene concrete.

- Main Markets

-

Hong Kong(China)

Hong Kong(China)

India

India

Russia

Russia

- Main Product

Related Products

Earth moving spare parts made in S Korea

Moulds

Factory Price Rotary Drum Dryer for sand, ore, slag, coal

Non-autoclaved Aerated Concrete Brick Machine Stacking Machi

IOREX