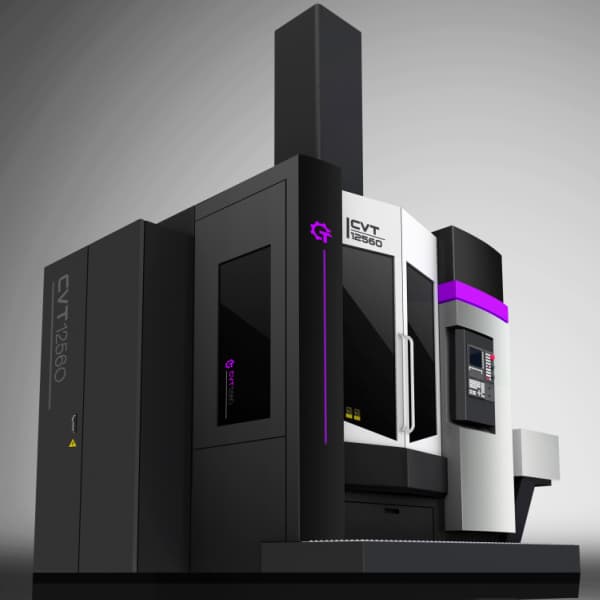

CVT112560-NC CNC VERTICAL TURNING LATHE

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Other Metal & Metallurgy Machinery

FUJIAN CHENGGONG MACHINE TOOL CO.,LTD.

- Verified Certificate

-

11

| Product name | CVT112560-NC CNC VERTICAL TURNING LATHE | Certification | - |

|---|---|---|---|

| Category | Other Metal & Metallurgy Machinery | Ingredients | - |

| Keyword | cnc lathe , vertical lathe , vertical turning lathe , cnc lathe machine | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | China | Stock | - |

| Supply type | - | HS code | - |

Product Information

Technical parameter:

Item | Unit | Specification | ||

Processing ability | Max. swing diameter | mm | 1250 | |

Max. turning diameter | mm | 1250 | ||

Max. height of workpiece | mm | 800 | ||

Spindle

| Speed range | r/min | 10~300 | |

Spindle bearing(front) | mm | 609.6 | ||

X/Z | X1 axis travel | mm | -50,+600 | |

X2 axis travel | mm | -600,+50 | ||

Z1 axis travel | mm | 800 | ||

Z2 axis travel | mm | 800 | ||

X1,X2 axis fast moving | mm/min | 12000 | ||

Z1,Z2 axis fast moving | mm/min | 8000 | ||

Motor output power | Spindle motor(rated/30min) | kW | 22 | |

X axis servo motor | N.m | 22 | ||

Z axis servo motor | N.m | 22 | ||

Tools holder | Tools holder type1 | station | 4 electric tool set | |

Tools holder type2 |

| 8 square ram | ||

Circle cutter size | mm | 32X32 | ||

Precision | Processing precision |

| IT6-IT7 | |

X1/Z1 position precision | mm | 0.018/0.020 | ||

X2/Z2 position precision | mm | 0.018/0.020 | ||

X1/Z1 repeat position precision | mm | 0.075/0.0150 | ||

X2/Z2 repeat position precision | mm | 0.075/0.0150 | ||

Overall size of machine | mm | 3000X2800X3600 | ||

Machine weight | Total weight | Kg | 8500 | |

System | CNC |

| GSK980TTc (double channel control) | |

Note: Manufacturer reserves the right to improve & modify without prior notice.

Features:

1. The lathe are our new design specifications of 1250, its economy, high efficiency and energy saving. It is good for the processing of the complex plate, auto wheel, shell and short shaft parts, it can be do the machining of the circular arc, inner and outer surface of the revolved body, end, groove parts etc.

2. The machine use single spindle, single tool head structure (four station electric tool set), use four jaw chuck for clamping. Main parts such as tool head, chuck, ball screw, rail line use China and foreign well-known manufacturers’ brand, it can ensure that the machine has the characteristics of high rigidity, high precision, high reliability.

3. The machine main parts are spindle, base, beam, tool head etc.

4. The machine has good economy, high efficiency, and low energy, it is good for Auto parts machining.

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Zhou Sijin

- Address

- Xinglian Industry area,Liucheng,Nanan city,Fujian province,China

- Company introduction

-

Fujian Chenggong Machine Tool Co., Ltd. was founded in 1995. We hold the tenet of "people-oriented, quality and quantity assurance, manage with good faith". Our company is situated in Chinese charismatic city - Quanzhou. Quanzhou is an old cultural city, which is the hometown of hero - Zheng Chenggong.

Current firm covers an area of 250 acres, the annual production of castings reach 3 million metric tons or more, capable of producing 50 tons of a variety of one-piece ductile iron, gray cast iron pieces. With a variety of mechanical processing of heavy equipment: floor milling machines, large CNC gantry milling machine, large gear-hobbing machine, large gantry planer, large-scale imports of CNC gantry rail grinding machine, etc.), and high-precision processing equipment (including coordinate measuring instrument, laser interferometer) , advanced detection methods, creating high-end Machine Tool products.

Company's main products: CK518, CK5116G single-column CNC vertical lathe, SCVT280, 350,400,500,630 double column CNC vertical lathe, CVT-280, 350,400,500,630 programmed double-column vertical lathe, C5116E single column vertical lathe, C5116E increasing the height of a single column vertical lathe widened, TX6111T horizontal boring and milling machine series. Product development and innovation are in the thriving, have been certificated by national experts, some products reach the domestic advanced level, thereby our company gained a higher praise in production technology.

- Main Product

China

China