Total Sputtering (Coating) System

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- South Korea

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

Sukwon Co., Ltd.

- Verified Certificate

-

17

| Product name | Total Sputtering (Coating) System | Certification | - |

|---|---|---|---|

| Category |

Vacuum Equipment & Parts

Metal Coating Machinery Glass Production Machinery Other Plastic Product Making Machinery |

Ingredients | - |

| Keyword | coating , machine , sputter , vacuum | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | South Korea | Stock | - |

| Supply type | - | HS code | 8414109090 |

Product Information

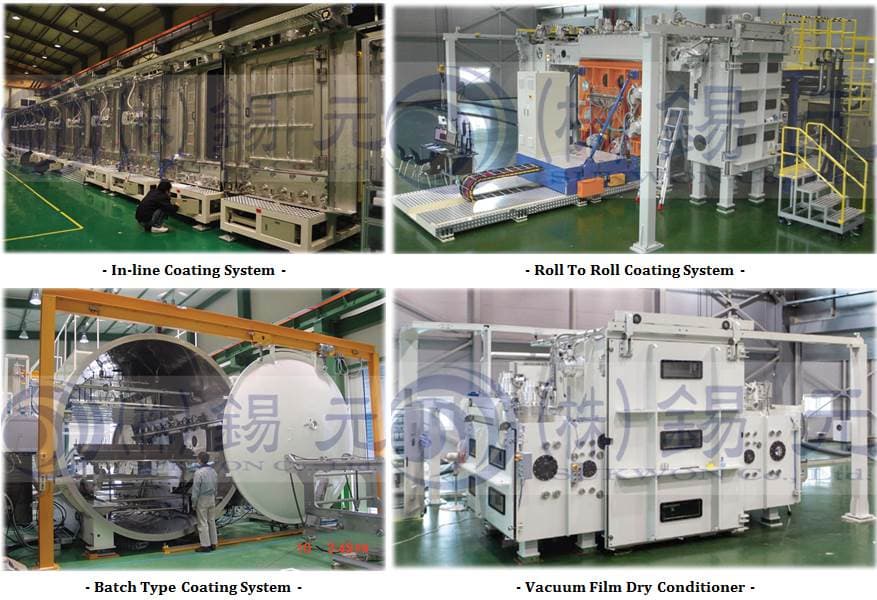

In-line Sputter System :

In-line Sputter System is equipment for coating a thin film on a flat substrate, such as Glass, in vacuum chamber and It is have a optimal competitive at continuous mass production.

System Type : Vertical & Horizontal Type

Substrate Size : Customer request (Max. 8.5G - 2200mm*2600mm)

Target : ITO, SiO2,TiO2, Nb2O5, AZO,AlN, Cu, Mo, AI, Ag, Cr, NiCr, NiCu etc.

(Metal, Oxide, Nitride, Carbide)

Roll To Roll Sputter System :

Roll To Roll System (Web coate)r is a coating equipment for functional film manufacturing, such as flexible display film (PET, PEN, PI, PC etc).

High speed deposition is possible while maintaining thickness of the deposition layer on top of a thin film.

System Type : 1 Drum Type (Max. 6 Dual Cathode)

2 Drum Type (Max. 12 Dual Cathode)

Substrate Size : Customer request (Film width max.1,600mm commercialization)

Batch Type Sputter System :

Batch Type System is type to built the substrate inside single chamber.

This system is advantageous in short-run production and provides a significant cost reduction effect.

System Type : Vertical & Horizontal Type

Substrate Size : Customer request

Application :

ITO Coating for Touch Panel, Metal Coating for Electrode, Filter Coating for PDP

TCO Coating for Solar Cell, Case Decoration of Mobile phone, EMI Shield Coating

Optical Coating, Large area glass Coating, Mirror & Lamp Coating in Automotive

AR / AG / Low-e Coating, etc

Vacuum Film Dry Conditioner System :

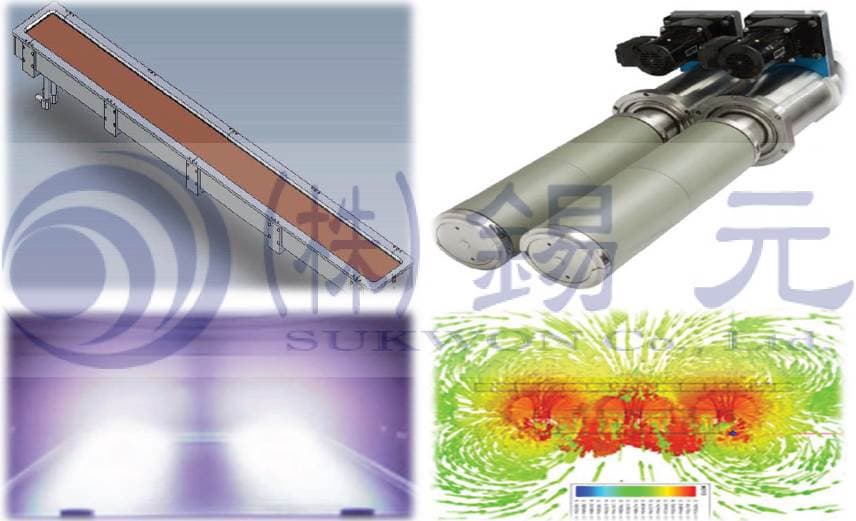

Cathode Design, Chamber Design :

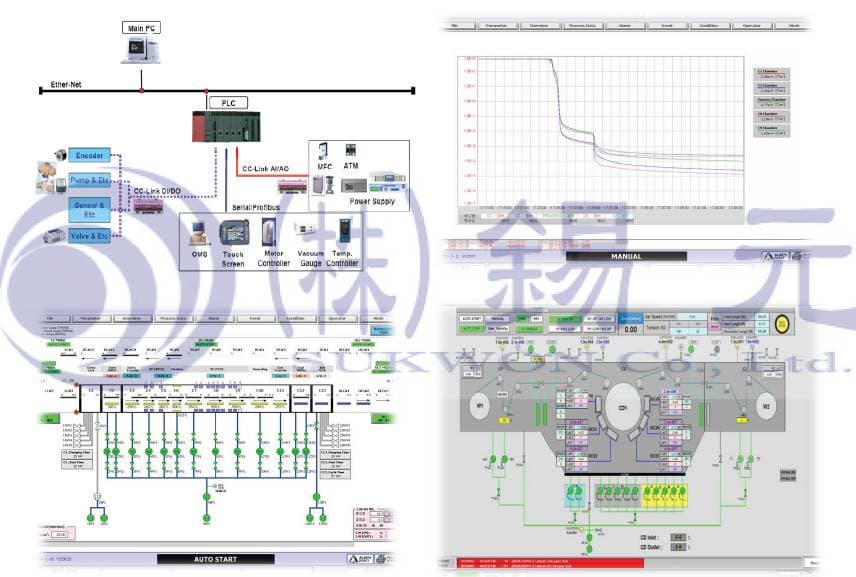

PLC, HMI, Full Auto Control & Monitoring System :

- Product Info Attached File

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Lee, Jong-yun

- Address

- 78-32, Cheomdangieop 5-ro, Sandong-myeon, Gumi-si, Gyeongsangbuk-do, Korea

- Product Category

- Metal Coating Machinery,Vacuum Equipment & Parts

- Year Established

- 1998

- No. of Total Employees

- 1-50

- Company introduction

-

Founded in 1998 under the spirit of challenge to 'Creating something out of nothing', Suk Won has been ceaselessly pursuing management innovation and technology development for new products. Suk Won has been supplying key display & digital coating equipment to large-scale enterprise and other leading companies in Korea over many years. In addition, we have been continuously developing vacuum coating facilities and technologies through technical tie-ups with foreign companies of the highest technological power.

Suk Won vacuum coating facilities cover a wide range from in-line and roll to roll web coater to batch-type coating facilities and custom-made facilities. Vacuum facilities manufactured by Suk Won are applied to multi-layered membrane manufacturing, TFT coating, ITO coating, EMI and colored glossy coating for mobile phones and conductive film coating. Suk Won is capable of manufacturing and supplying these equipment because we have developed technologies for high-transmission, transparent, conductive multi-layered membrane and photovoltaic sputtering facilities.

In addition, Suk Won has established close relationships for technological development with leading universities and research labs in Korea.

- Main Markets

-

China

China

India

India

U.S.A

U.S.A

Viet Nam

Viet Nam

- Factory Information

-

SUKWON Co., Ltd.

- Main Product

Related Products

HIGH ULTIMATE VACUUM PUMP

FITTINS-1

Carbon Carbon Composite Bolt Nut Screw Plate

Metal Doctor

SHIP PARTS / ENGINE PARTS / PUMP / PURIFIERS / OWS / ELECT

South Korea

South Korea