WES-3000, SPOT WELDING CHECKER

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- South Korea

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Welding & Soldering Supplies

Monitech

- Verified Certificate

-

11

| Product name | WES-3000, SPOT WELDING CHECKER | Certification | - |

|---|---|---|---|

| Category | Welding & Soldering Supplies | Ingredients | - |

| Keyword | weld checkers , welding inspection machine , welding monitoring , welding expert | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | South Korea | Stock | - |

| Supply type | - | HS code | - |

Product Information

WES-3000(Welding Expert SPOT)

│ DESCRIPTION │

This is the equipment enabling to produce, analyze and manage the output in the forms that the users ask by calculating current, voltage, welding time, the amount of input heat, quality assessment (in-line), welding force, impedance in real time at the time of welding work on the ARC(Gas flow is optional).

Welding Expert: ARC from Monitech Co., Ltd. is the equipment enabling to produce, analyze and manage the output in the forms that the users ask by calculating current, voltage, welding time, the amount of input heat, quality assessment (in-line), welding force, impedance in real time at the time of welding work on the ARC. (※ Gas flowis optional)

Data measured through current, voltage and gas flow sensors are as follows:

- Welding Expert: ARC : measurements of current, voltage, gas flow, welding time and calculation of impedance and amount of the input heat

│ FEATURES │

- It's easy to install

- It can be easily installed by anyone with simple current, voltage, flow rate and welding force sensors. - It supports various communication interfaces.

- It supports various communication protocol such as RS-282, RS-485, LAN(TCP/IP) and WiFi etc. - It can be used as management terminal controlling multiple welding machines simultaneously when configured in network.

- When configured in network communication system, this enables to set up various real time quality assessment system as it can control the welding data from up to 20 machines by using in-line software and I/O. (This is usable as stand-alone equipment. Please contact us if you need to configure this equipment to manage the in-line control of more than 20 welding machines) - It is able to output the contact of the external abnormal signals through the function to set the upper and lower limits.

- By setting up the upper and lower limits internally, it produces output of the contact (non-contact) through the interface in case that the results is off the specified limits. - It supports a large amount of SD memo.

- It enables to save automatically, analyze and assess all welding data as it provides enough built-in SD memory capacity up to 32GB. - It enables to produce data analysis without limitation and automatic reports.

-It's possible to analyze and manage data and produce report automatically by using the dedicated S/W - This is the most suitable for the real time management of SQ assessment, 5 STAR assessment and welding data.

- It is easy to operate.

│ SPECIFICATION │

Name |

Specification |

Quantity |

Remarks |

SPOT |

|||

Main Body |

220(W) X 189(D) X 110(H) |

1 |

|

2.5 Kg |

|||

Current Sensor |

Max. 200kA |

1 |

|

Voltage Clip |

Max. 10V |

1 |

|

Extension Cable |

Standard 5M |

1 |

Option |

Welding Force |

Max. 2 Ton |

1 |

Option |

Power Supply |

AC100 / 240V, 50 / 60 Hz(Free Voltage) |

1 |

|

- Product Info Attached File

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Hwang dong-soo

- Address

- 94, Saebyeok-ro 223beon-gil, Sasang-gu, Busan, Korea

- Product Category

- Welding Equipment

- Year Established

- 2005

- No. of Total Employees

- 1-50

- Company introduction

-

- Main Product

Related Products

Metal Doctor

E6013 Welding electrode for carbon steel

MANUAL TIP DRESSER

Inverter DC Tig Welder

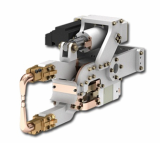

SPOT WELDING GUN

South Korea

South Korea