R2R Rotary Screen Printer System

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Brand name

- DCN-RSCP-01A

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- roll to roll, rotary, screen printer, printed electronics

- Category

- Printing Machines

DCN.Co.,Ltd

- Verified Certificate

-

11

| Product name | R2R Rotary Screen Printer System | Certification | - |

|---|---|---|---|

| Category | Printing Machines | Ingredients | - |

| Keyword | roll to roll , rotary , screen printer , printed electronics | Unit Size | - |

| Brand name | DCN-RSCP-01A | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | - |

Product Information

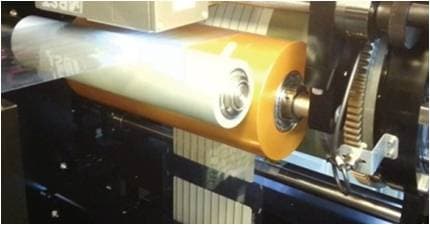

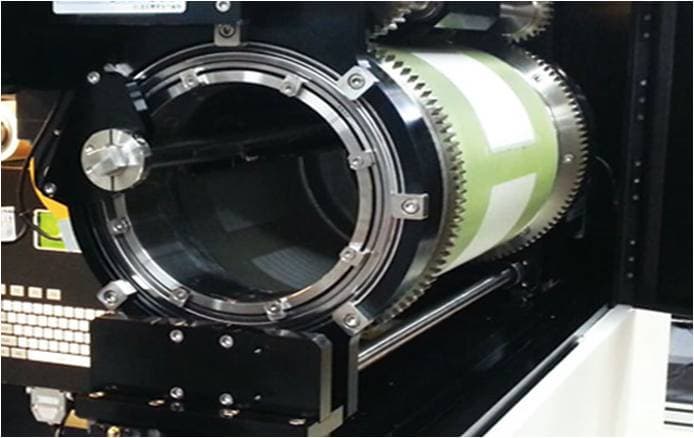

- R2R Rotary Screen Printing System is an optimized device for manufacturing flexible OPV solar battery elements

- Rotary screen printing process is used to form OPV cathode. ITO layer is formed by front coating on the thin film. Transition layer and active layer applied with PEDOT:PSS and P3HT:PCBM materials use slot or gravure process for the printing. Rotary screen printing process prints cathode pattern in the last process.

- Available to combine with laminator through drying and hardening. Hardening and drying specifications are to be applied depending on customer requirements.

- E.P.C lateral controlling unit is applied to arrange the width direction of web.

- Pre-processing including anti-static ionizer maintains the optimal condition if printing the surface of web via improvement of web surface and prevention of static.

-. Make the condition to incorporate N.I.R hardening and hot air drying unit through drying and hardening for the printed patterns

-. Line and contrast control system arranges the web axis direction to optimize the transfer the web.

-. Web tensile controller consistently prevents from losing the tightness in the printing.

-. Memory (recipe) function remembers printing process conditions that is conveniently loading at any time.

- Product Info Attached File

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Byun, Chang-wan

- Address

- (#B-512, Yongsan-dong) Migun Techno Wold 2, 187, Techno2-ro, Yuseong-gu, Deajeon-city, 305-500 Korea

- Product Category

- Clinical Analytical Instrument,Machinery & Parts,Printing Machines

- No. of Total Employees

- 1-50

- Company introduction

-

“ Printed Electronics New Technology ” DCN Corporation was established in 2007 pioneering in the field of printing industry by developing Roll Printer as a device of Gravure Offset Printing unit for the first time in Korea making a further step to be the company specializing in the process of printing and electronic area. Starting from the development of experimental devices when insufficient amount of infrastructure was provided compared to passion and high interest in the field of printed electronics industry, DCN Corporation has been exclusively developing devices for diverse processes that our devices are being utilized in each of the research areas including printing process, electronic materials, and components. DCN Corporation has been developing various printing process devices including Roll Printer, Table Slot Die Coater, Thermal Roll Imprinter, Screen Printer, and Bar-Blade Coater accumulating technical know-how and also producing and incorporating R2R continuous process system applied pilot devices based on them. We are all feel proud of how our company's devices are being used in the field of growth and technical development in the area of printing and electronic industry and also responsible to lead the area. All the employees of DNC Corporation will exert the greatest effort to be the best in the field of printing and electronic process via steady technical development and innovation. Thank you.

- Main Markets

-

South Korea

South Korea

- Main Product

Related Products

AIR950(Auto Ink Recharger)HP950,951/HP932,933

Supvan TP76E tube printer, cable id printer, wire marking

Retort pouch

Enterpack Heater _EHQ series

TEXTILE PRINTING MACHINE [NSHI CO., LTD]