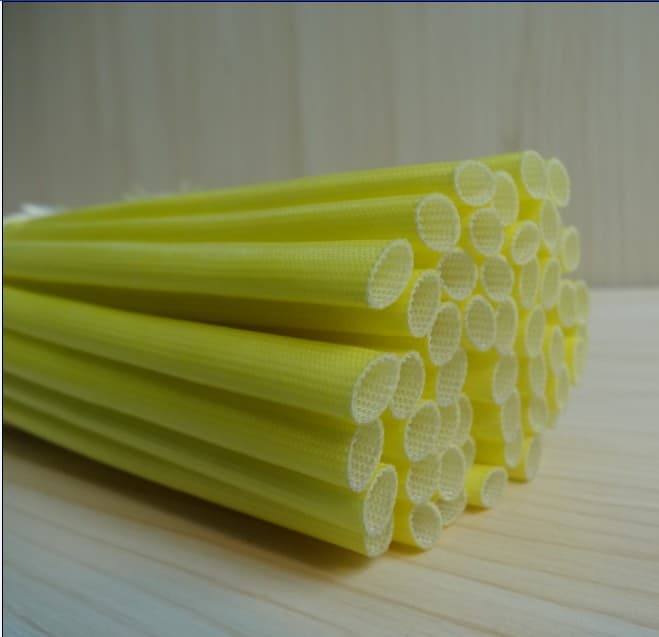

Acrylic coated fiberglass sleevings

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Brand name

- High-Go

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

Chizhou Jiuhua High-Go Electrical & Material Co.,Ltd

- Country / Year Established

-

China

/

China

/

- Business type

- Others

- Verified Certificate

-

12

| Product name | Acrylic coated fiberglass sleevings | Certification | - |

|---|---|---|---|

| Category |

Electrical Components & Telecoms

Heat Insulation Materials |

Ingredients | - |

| Keyword | acrylic , heat resistant , fiberglass braided sleeving , high temperature fiberglass sleeving | Unit Size | - |

| Brand name | High-Go | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | - |

Product Information

2740 Glass Textile Sleeving With Acrylic Resin Based Coating

(Standard: JB/T8151.3-1999, IEC60684-3-403:1988)

Glass textile sleeving with acrylic resin based coating is manufactured with non-alkali fiberglass braided sleeving and coated it with acrylate latex and then heated it to form B grade insulating sleeving. It possesses outstanding property of dielectric, reliable heat resistance and elasticity, benzene resistance and oil resistance. It can be used as wiring insulation and mechanic protection for electrical machinery, electric apparatus, electric appliances, etc.

Properties:

1. Length: The standard length of this sleeving is 1000mm, continuous length could be negotiated.

2.Appearance: Smooth surface, clear and neat ends.

3. Elasticity: At 20±5% and 65±5%RH, the coating of the sleeving should not crack or appear detached after the sleeving has been wound around the specified mandrel for 1 hour.

The coating should not crack or appear detached after the sleeving has been treated for 2 hours at a temperature of 10oC to 15oC below zero.

After the sleeving has been treated at a temperature of 130±2oC for 24 hours and then wound around a specified mandrel at the room temperature of 20±2oC, the coating should not crack or appear detached.

4. Oil resistance: The coating should not crack or appear detached after the sleeving has been dipped in transformer oil for 24 hours at a temperature of 105±2oC,but the colour of the sleeving grow darker is allowed.

5. Benzene resistance: The coating should not be sticky or show delaminating when the sleeving keep in methyl benzene at a normal atmospheric temperature for 4 hours.

Note: The breakdown voltage for the sleeving which inner diameter is or below 1.5mm, should not be lower than 75% of the specified voltage.

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

Chizhou Jiuhua High-Go Electrical & Material Co.,Ltd

- Country / Year Established

-

China

/

China

/

- Business type

- Others

-

12

- President

- Mr. Xie

- Address

- No.889 Yishan Road, Shanghai,China

- Product Category

- Heat Insulation Materials,Industrial Supplies,Insulator

- No. of Total Employees

- 51-100

- Company introduction

-

We, Chizhou Jiuhua High-Go Electrical & Material Co.,Ltd are specializing in manufacturing and exporting all kinds of fiberglass sleevings since 1996. Our main products include silicone fiberglass sleevings, PU fiberglass sleevings, acrylic fiberglass sleevings, self extinguishing sleeves, PVC sleeves and fire-protection sleeves etc which are provided with high quality and competitive prices.

- Factory Information

-

Chizhou Jiuhua High-Go E & M Co.,Ltd

- Main Product

Related Products

[M2I Corporation] XTOP07TW-LD-E HMI TOUCH PANEL M2I TOP

PCM Cable 10 Pair

HLF 600 Coaxial Cable

Hi-Fix Board

SCR thyristor module infienon IGBT Mainly Products