BF BAG FILTER DUST COLLECTOR

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Brand name

- BLACK HOLE

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- bag filter, collector, dust collector

Myungjin Machinery Ind. Co., Ltd

- Verified Certificate

-

11

| Product name | BF BAG FILTER DUST COLLECTOR | Certification | - |

|---|---|---|---|

| Category |

Other Machinery & Industry Equipment

Cleaning Brushes & Dusters Filters Filter Bags |

Ingredients | - |

| Keyword | bag filter , collector , dust collector | Unit Size | - |

| Brand name | BLACK HOLE | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | - |

Product Information

What is the bag filter dust collector?

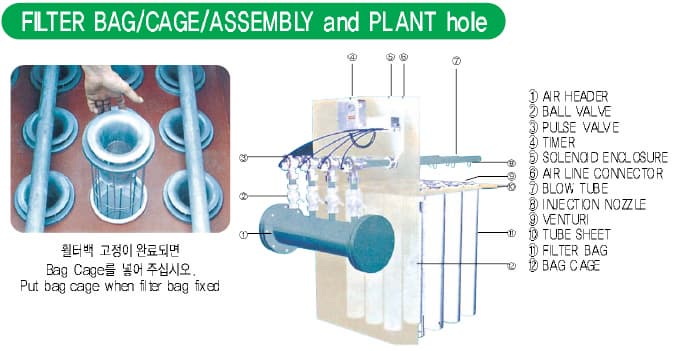

The bag filter dust collector is the equipment most widely used among all other systems separating dust particles from discharged gases. The operating principle of bag filter dust collector comes from the filtration process passing the discharge gases containing variety of dusts through the multiple numbers of filters as installed in parallel arrangement.

At the moment, the filtration process performed by the filter elements only at the initial stage, demonstrating filtration effect oriented from the dust layer accumulated executing itself as supporting material as the operation time lapses.

Further, the fine dust particles piled up at dust layer demonstrate the high dust collecting efficiency allowing stable continuous operation, capable of treating massive amount of airflow with filtering speed adjustment.

The bag filter dust collecting equipment provides over 99% of operating efficiency with the particles of over 0.5µm, and substantially high removing efficiency even with the particles of 0.01µm.

The selection of bag filter material requires the thorough consideration on the characteristics, temperature and other elements of dirty gases.

FEATURES

- Wide variety of dusts collected with high dust particle collecting efficiency

- Applicable to highly concentrated dirty gases, and capable of treating diverse amount of gases.

- Using of bag filters of fiber or pre-treated grain types applicable for highly efficient collection of dusts and polluted gases below 1µm size.

- Damp materials, concentrated moist and adsorbed contents require the crusty caking of bag filter, or Plugging or special facility for the purpose.

- Life span of bag filter long with less abrasion of filter bag caused by dust.

- Operation under highly concentrated dirty gases thanks to the steady pressure loss rising speed.

- Stable continuous operation applicable with constant pressure loss performed by continuous dust removing system.

APPLICABLE SITES

Mineral plant, Timber mill, Cement plant, Chemical plant, Pharmaceutical factory, Dying jobsite, Painting site, Plastic industry, Foodstuff industry, Feed factory, Granary factory, Dust generating jobsite, Flour mill, Fertilizer factory, and other particle material generating jobsites.

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Kim Hwang Ja

- Address

- 1663-5, Seongso 5th Industrial complex, Secheonri, Dasaeup, Dalsungkun, , Daegu, Korea

- Product Category

- Machinery & Parts,Machinery Parts Processing Services

- No. of Total Employees

- 1-50

- Company introduction

-

“BLACK HOLE” DUST COLLECTOR PRODUCTS offered by the Myungjin Machinery Ind. Co., Ltd. allow flexible custom designing as per the particular natures of jobsites, specific equipment characters, postures of operators and types of dusts involved. The employees and management of Myungjin Machinery Ind. Co., Ltd. are committed to present the satisfaction to customers with no simple portable collectors but custom manufactured dust collectors exactly fitting to each particular jobsite condition based on the technologies and trust accumulated to date for 26 years.

- Factory Information

-

MYUNGJIN

- Main Product

Related Products

Date Pin (Date Core)

AIRLESS PUMP- YL 731

NEMA17 42mm stepper motor with driver or controller

AIS3000 HD

Airless Pump (Ratio 63:1 Airless Pump)

South Korea

South Korea