MIDAS Plus

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Brand name

- Mirero

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- software, midas plus, standard analysis, statistical analysis

- Category

- Machinery & Parts , Computer Software

MIRERO SYSTEM CO.,LTD

- Country / Year Established

-

South Korea

/

South Korea

/

- Business type

- Others

- Verified Certificate

-

17

| Product name | MIDAS Plus | Certification | - |

|---|---|---|---|

| Category |

Machinery & Parts

Computer Software |

Ingredients | - |

| Keyword | software , midas plus , standard analysis , statistical analysis | Unit Size | - |

| Brand name | Mirero | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | - |

Product Information

MIDAS Plus

Integrated Yield Management System for Semi-conductor Manufacturing Process

This system is designed to automatically collect and control the process data. measuring data (Defect, Bin, Eletrical parametric, Fail Bit, Metrology, WIP) in an ingrated way MIDAS Plus will help you identify and take corrective actions against the cause of any lower productivity through the systemic control and analysis of the quality data.

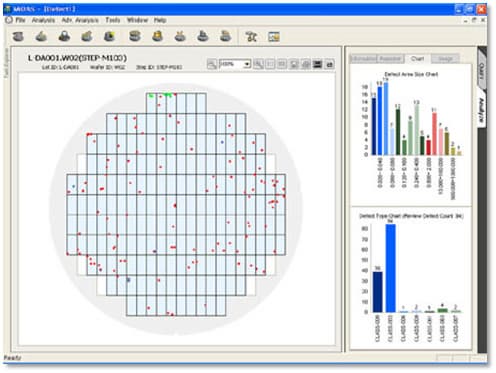

01. Standard Analysis

- Analyze the data by displaying the wafer map based on the data collected (Defect file, CP file)

- Types of analysis screen : Defect Map / Defect & Bin Map / Defect & Fail bit Map / Defect & Bin & Fail bit Map

02. Statistical Analysis & Chart

- Kill Ratio function : Indicate the numeral impact of defect by layer on yield. using the final yield data and defect data in the manufacturing process

- Yield Prediction : Predict the yield of the wafer being processed, using the pre-determined kill ratio

- Fail Region Type Chart : Display a chart showing the matching degree between fail-bit and defect, using the fail bit information, and lacation information provided by the defect file.

- Various charts : Provide charts by defect size and type (Pareto, Trend, Distribution, Histogram Chart)

- Can define and enter the data required for the system operation and revise the existing data

(Device, Step (Layer), Defect Size, Bin value registration)

03. Complete Image Database

- Various image search function (lot, wafer, step, date, chart...)

- Provide interface for a variety of equipment (CD-SEM, Review Station, Microscope, FIB, V-SEM)

- Search function for defect history

- Various image processing function (Gamma, contrast, compression...)

- Various image measuring function (width, height, diagonals, area...)

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- KIM, ZUNG-KN

- Address

- #2905 U-Tower, 120 Heungdeok Jungang-Ro, Giheung-Gu, Yongin-Si, Gyeonggi-do, 463-010, KOREA

- Product Category

- Computer Software,Machinery & Parts

- No. of Total Employees

- 51-100

- Company introduction

-

Mirero System Co., Ltd. is an outstanding Image solution Provider located in Seoul, South Korea. Since Mirero Inc. opened its image analysis laboratory in 1991, we have been esteemed as a pioneer of image solution products in Korea. As our company name, Mirero meaning 'toward future', we have explored undeveloped area with our young challenging spirit and have tried to meet every needs

of our customer. Now then we cover various range of fields such as semiconductor, life sciences, metallurgy, etc.

Mirero Inc. has enjoyed high reputation for our total user-friendly image inspection solutions and technical support. With powerful image analysis tools, you can have the best results and solutions from your image sources.

We highly appreciate your visiting our web site and invite you to explore our business page to learn more about our products. If you have any question or comments, please contact us.

- Main Markets

-

China

China

South Korea

South Korea

- Main Product

Related Products

Torrington Bearing

_2.jpg)

Turbowin Turbo Blower (WL Series)

KBC Bearing

Modbus Device Recorder

NEMA17 42mm stepper motor with driver or controller