BESTTOME -T300

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- South Korea

- Brand name

- SsaulBestech

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- cutting machine, besttome, technical glossary

SsaulBestech

- Country / Year Established

-

South Korea

/

South Korea

/

- Business type

- Others

- Verified Certificate

-

12

| Product name | BESTTOME -T300 | Certification | - |

|---|---|---|---|

| Category |

Machinery & Parts

Other Machinery & Industry Equipment Other Metal & Metallurgy Machinery |

Ingredients | - |

| Keyword | cutting machine , besttome , technical glossary | Unit Size | - |

| Brand name | SsaulBestech | Unit Weigh | - |

| origin | South Korea | Stock | - |

| Supply type | - | HS code | - |

Product Information

BESTTOME -T300

l Technical glossary for T300 and T400 l

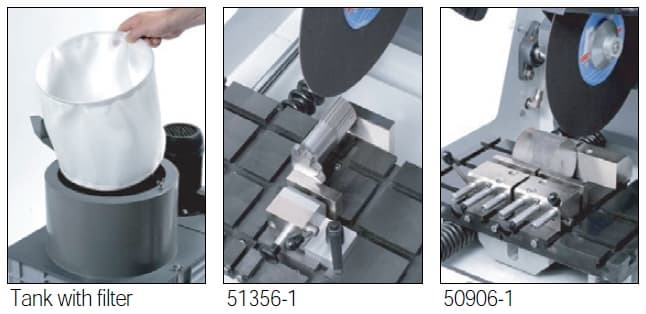

Saving settings : The last parameters applied can be saved. This is particularly helpful for mass cutting, or for cutting identical workpieces.

Automatic regulation : An electronic device measures the effort of the various motors and regulates the forward motion of the working table during automatic cycles. Maximum and minimum thresholds may be easily configured by the operator to adapt the parameters according to the types of workpieces and materials.

It is also possible to configure response times for adjustment.

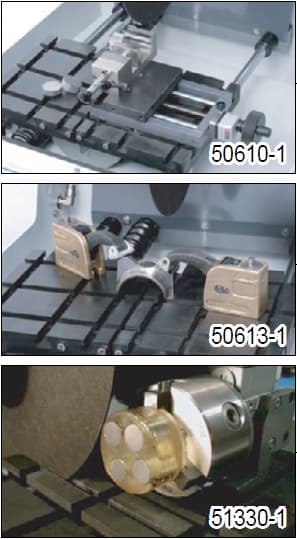

Pulsation cutting : the BESTTOME T 300 has 2 cutting modes: direct and pulse cutting. With the direct mode, automatic forward motion is continuous, and only speed is regulated if necessary. With the pulse system mode, forward motion is alternated with stops for optimum cooling of the workpiece. Forward motion and stopping time may be configured separately per 1/10th of a second. Forward motion speed may also be controlled.

l Operating for T300 and T400 l

BESTTOME T 300/400 is a robust, powerful and reliable cutting machine integrating the latest technology to ensure easy use and simple maintenance. ø 300 or 400 mm cutting disks combined with variable speeds allowing for optimum cutting results with all types of materials. The design means that large and bulky shaped components as well as bars can be cut.

- With manual cutting, the user may adjust the disk speed before or while cutting without needing to stop the machine. It is also possible to move the table forward or backward during cutting to permanently modify the cutting angle: hard to handle materials may therefore be cut without having to use excessive effort.

- With automatic cutting, the following functions are possible:

- variable disk speed for precise disk adaptation

- variable movement of the table for rapid cutting of easy to handle materials or small items, and slow cutting of hard to handle materials or large items

-adjust thresholds to optimize forward speed according to the resistance sensed during cutting and to accelerate cutting for optimum performance

- direct cutting function for rapid processing of easy to handle materials

- pulse cutting function for hard to handle materials, enhancing the cooling down of the workpiece and the regeneration of the disk

- programmable cutting length give more time for mass cutting and stops cutting at a set distance.

- rapid return function at the end of cutting and automatic stopping of the machine allows operator free cutting.

- rapid positioning of the table reduces adjustment time prior to cutting. - The powerful and silent motor is controlled by the frequency inverter to increase long term reliability and to ensure a high level of safety with progressive acceleration (no sudden movements in transmission) and the immediate stopping of the disk. The frequency inverter will also ensure a constant torque independently to the applied load.

Width : 645mm

Depth : 970mm

Height : 945mm (+Cabinet : 1450mm)

Weight : about 120kg

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Hu Sun, Kim

- Address

- #206 building B, SK twin tower, 345-9 Gasan-dong, Geumcheon-gu, Seoul, Korea

- Product Category

- Machining Services

- No. of Total Employees

- 1-50

- Company introduction

-

We are manufacturing company established 1997 in South Korea, developing testing machine such as cutting machine, mounting machine, polishing machine and importing those including consumables as well.

- Main Product

Related Products

UIM2901-5A MACH3 break out board for CNC

Portable line boring machine, Elsa Supercombinata EASY Compact

Flange

_2.jpg)

Cable and Wire harness tester (MHT-610 / 705)

KBC Bearing