NANO-AIS

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Brand name

- FRONTICS Inc.

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

FRONTICS Inc.

- Verified Certificate

-

12

| Product name | NANO-AIS | Certification | - |

|---|---|---|---|

| Category |

Other Machinery & Industry Equipment

Testing Equipment |

Ingredients | - |

| Keyword | instrumented indentation technique ndt , on-site structure ndt , test equipment , on-site non-destructive testing | Unit Size | - |

| Brand name | FRONTICS Inc. | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | - |

Product Information

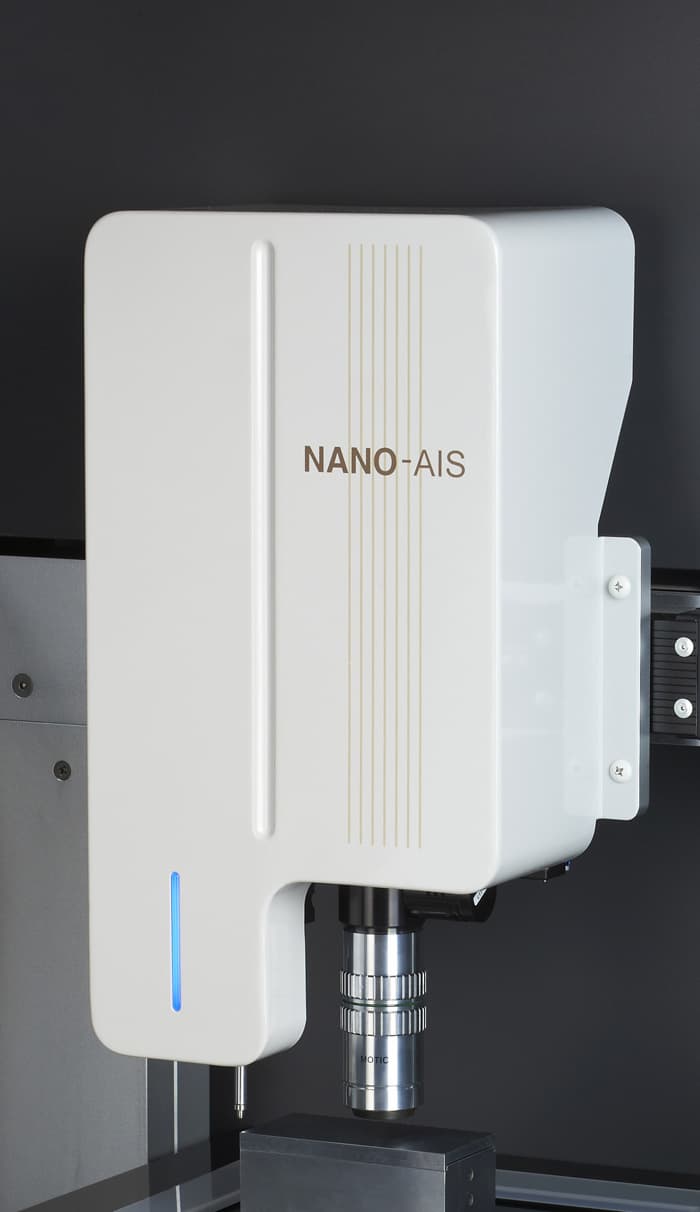

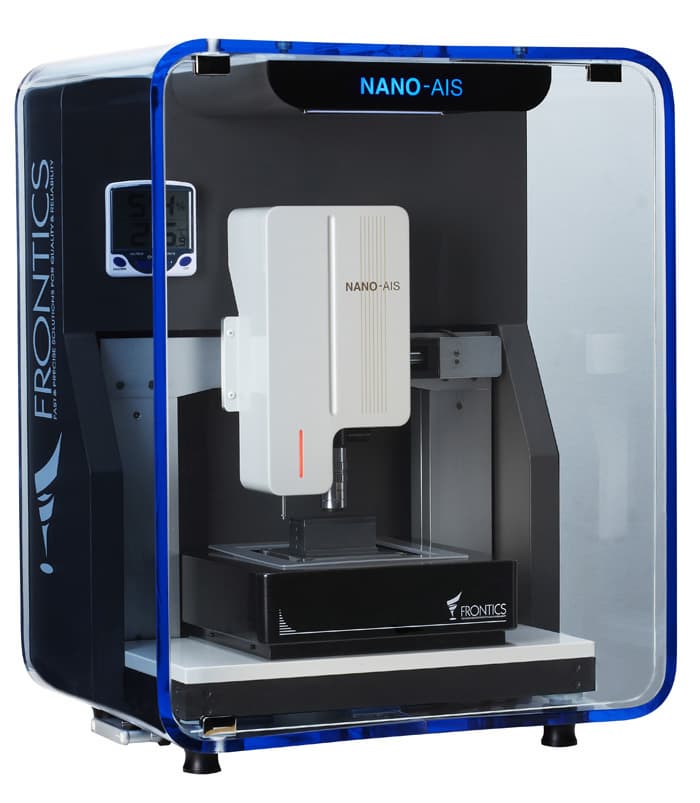

NANO-AIS

Advanced Indentation System

Unlike existing nano equipment, Material Properties Tester NANO-AIS is a testing equipment that evaluates residual stress and tensile properties at nano scale. Using instrumented indentation technique, we obtained indentation load –displacement curve and it was applied to self-developed technology to evaluate residual stress between the layers, and tensile properties of grain and grain boundary. NANO-AIS uses Piezo Actuation System for precise control of the load and approval and it also features to block external environmental elements such as outside temperature and vibration.

Furthermore, it comes with high magnification optical microscope for the test location, and it is replaceable with special microscope like atomic force microscopy as user demands. For user’s convenience, it comes with software that features various automated testing system, analysis and reports preparation.

│Concept│

- Measurement of advanced mechanical properies : Tensile strength , Residual stress, etc

- Mechanical mapping

- Local region test

- Automatic test & Analysis & Reporting

│Application│

- Coatings/Thin films

- Polymer development and testing

- Semiconductors/bond pad properties

- Metal-matrix composites

- Bio-materials

- Mechanical properties in micro phases

│Specification│

|

Size

|

630 x 800 x 470 mm

|

|

Max. load

|

200 mN

|

|

Load resolution

|

10nN

|

|

Depth resolution

|

0.05 nm

|

|

Movement system

|

X-Y asis stage

|

|

Indenter

|

Berkovich indenter, Spherical Indenter

|

|

Vision

|

X2000, Digital camera, Image SW

|

※NANO-AIS Software

- Tensile properties software and Nano-hardness based on the theory of IIT (Instrumented Indentation Technique)

- Possible to measure and analyze in real time by using a desktop

- Possible to load All-in-one software (hardness, fracture toughness software)

- Access code assignment method through logging in

- One-click automatic test (Full automatic software) and adopting software to change a testing location automatically

- Embedding auto Multi-mapping, selecting, image test modules

- Embedding a manual testing module for the user convenience (Direct Control Method)

- Video focus Control and testing location control function (Right-Left)

|

Tensile Properties

|

Option

|

|

Residual Stress

|

Option

|

|

Hardness

|

Installed

|

|

Fracture Toughness

|

Option

|

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- kwangho Kim

- Address

- Gasan-dong, Byucksan Digital Valley 6-cha,Suite 407, Geumcheon-gu, Seoul, Korea

- Product Category

- Other Measuring & Gauging

- Year Established

- 2000

- No. of Total Employees

- 1-50

- Company introduction

-

FRONTICS is a specialized company in “Material Properties Test Equipment” founded in September, 2000. Based on research results accumulated for a long time, we have developed and supplied assessment devices for properties and residual stress of various structures and materials coping with the demand of industrial and public institutions. FRONTICS AIS series of nondestructive inspection machines. Using the instrumented Indentation Technique (IIT), these machines can test tensile strength, residual stress and fracture toughness of materials from micro/nano dimensions to large metal structures. FRONTICS nondestructive inspection machine can prevent industrial accidents, ensure compliance with government and technical standards, save time and money with on-site testing, and reduce the manufacturing cost of structures.

- Main Product

South Korea

South Korea