MICRO-AIS

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Brand name

- FRONTICS Inc.

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

FRONTICS Inc.

- Verified Certificate

-

12

| Product name | MICRO-AIS | Certification | - |

|---|---|---|---|

| Category |

Other Machinery & Industry Equipment

Testing Equipment |

Ingredients | - |

| Keyword | instrumented indentation technique ndt , on-site structure ndt , test equipment , portable on site non-destructive test equipment | Unit Size | - |

| Brand name | FRONTICS Inc. | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | - |

Product Information

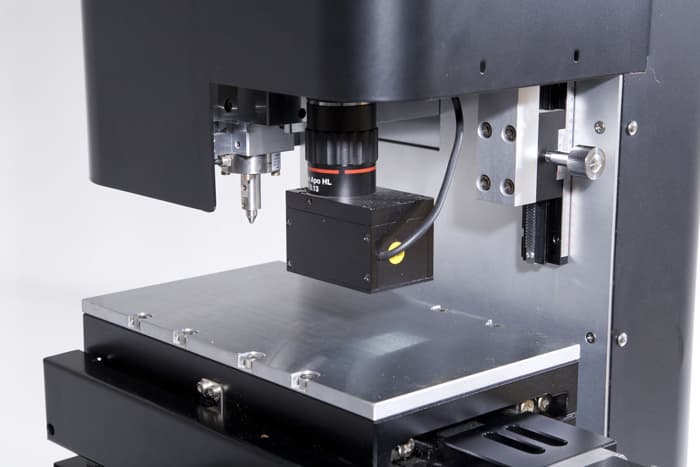

MICRO-AIS

Micro Advanced Indentation System

Test range: scores of um

Analysis: Tensile Properties,

Residual stress

Method: Instrumented Indentation Test

- ISO/TR 29381

- KS B0951

- KS B0950

- KEPIC MDF A370

│Characteristic│

- Evaluation of Residual stress using IIT

- Quantitative analysis

- User-friendly Interface

- Automatic Moving System

- Vision System

│Application│

- General hard coating layer

- Protective coating layer on glass

- Sol-resistant coating layer

- Coating layer of electronic material

- Thin film

│Specification│

|

Size

|

328 X 305 X 900 mm

|

|

Max. load

|

2000 gf (Resolution: 10 mgf)

|

|

Stroke

|

15 um (Resolution: 10 nm)

|

|

Test range

|

scores of um

|

|

Vision

|

X1500, Digital Camera, Image SW

|

|

Method

|

Instrumented Indentation Test

|

|

Analysis

|

Tensile Properties,Residual Stress

|

※Micro AIS

Micro AIS evaluates tensile properties and residual stresses of the test subjects of very small dimensions (micrometers), such as fine-welded parts and coated layers. Through the Vision system and automatic stages, the test position can be identified and designated. Moreover, precision test for major parts is made available through automatic and screening tests.

- Items

- Micro Vickers Hardness (Max. load 2000 gf)

- Residual Stress

- Yield strength

- Tensile strength

- Elastic modulus

- Specification

|

Model

|

Micro AIS

|

|

Size

|

328 X 305 X 900 mm

|

|

Max load

|

2000 gf

|

|

Load resolution

|

0.01 gf (10 mgf)

|

|

Depth resolution

|

0.01 um (10 nm)

|

|

Stage

|

X-Y axis stage, Z axis stage

|

|

Operating Temp.

|

-10 ℃ ~ 40 ℃

|

|

Power

|

220 Vac

|

|

Vision

|

X1500, digital camera, image SW

|

|

Indenter

|

Micro Vickers indenter Dia.0.05mm spherical indenter

|

|

Used

|

Evaluation of residual stress (Micro range)

|

※Micro AIS Introduction

- Features

Perfect implementation of IIT in the micrometer range

- Application of ISO/TR 29381 in the micrometer range

- Application of KS B0950 and KS B0951 technology

- Application of IIT eliminates human errors

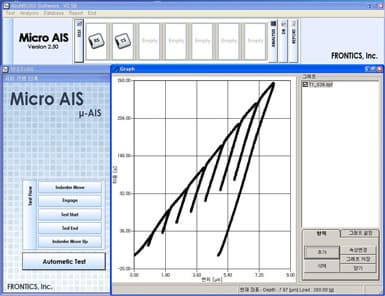

User-Friendly software

- Easy to use Window-based software

- Evaluation of the tensile properties and residual stresses is made available immediately after the test

- User convenience has been enhanced with automatic malfunction checking and data error inspection

- Multi-point testing system

Implementation of automated testing based on the Automatic Moving system and the Vision system

- Tests can be automatically completed with an initial setup of test conditions

- Maximum efficiency of personnel and time through repeated testing

- Matrix test function: Test procedures for selected image ranges

- Selecting test function: Test procedures for randomly selected positions

- Matrix-selecting test function: Test procedures for various randomly selected locations in checkerboard format

- Automatic moving system

- Enables fine positioning and adjustment

- For precise controlling and automatic testing

- System: X, Y Stage

- Resolution: 1 um

- Moving rate: 1 ~ 30 mm/min

- Vision system

- Enables fine positioning and adjustment

- For precise controlling and automatic testing

- Magnification: X150 (Max.: X1200)

- Max. Distance: 100 mm

- Saving type: Digital image capture

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- kwangho Kim

- Address

- Gasan-dong, Byucksan Digital Valley 6-cha,Suite 407, Geumcheon-gu, Seoul, Korea

- Product Category

- Other Measuring & Gauging

- Year Established

- 2000

- No. of Total Employees

- 1-50

- Company introduction

-

FRONTICS is a specialized company in “Material Properties Test Equipment” founded in September, 2000. Based on research results accumulated for a long time, we have developed and supplied assessment devices for properties and residual stress of various structures and materials coping with the demand of industrial and public institutions. FRONTICS AIS series of nondestructive inspection machines. Using the instrumented Indentation Technique (IIT), these machines can test tensile strength, residual stress and fracture toughness of materials from micro/nano dimensions to large metal structures. FRONTICS nondestructive inspection machine can prevent industrial accidents, ensure compliance with government and technical standards, save time and money with on-site testing, and reduce the manufacturing cost of structures.

- Main Product

Related Products

High Speed Door_ KAD-2000, cua cuon nhanh

Korean children's clothing chichikaka brand

Marine Loading Arm

Audio Grade PCIe Host Card – tX-USBexp

Date Pin (Date Core)

South Korea

South Korea