AIS2100

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Brand name

- FRONTICS Inc.

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

FRONTICS Inc.

- Verified Certificate

-

12

| Product name | AIS2100 | Certification | - |

|---|---|---|---|

| Category |

Other Machinery & Industry Equipment

Testing Equipment |

Ingredients | - |

| Keyword | instrumented indentation technique ndt , on-site structure ndt , test equipment , portable on site non-destructive test equipment | Unit Size | - |

| Brand name | FRONTICS Inc. | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | - |

Product Information

AIS2100

Evaluation System for Tensile Properties using

Instrumented Indentation Test

- ISO/TR 29381

- KS B0950

- KEPIC MDF A370

│Features│

- Non-destructive tensile properties evaluation

- On-site test and analysis

- Testing of welded areas

- Allows regulation of testing conditions

- Applies ‘Pre-Qualification’ method to construction sites and facilities

│Specification│

|

Size

|

180 x 180 x 430 mm

|

|

Weight

|

7 kg

|

|

Max. load

|

300 kgf (Res.: 5.6 gf)

|

|

Stroke

|

40 mm (Res.: 0.1 um)

|

|

Loading rate

|

0.05 ~ 30 mm/min

|

|

Communication

|

RS-422(Wireless - Bluetooth)

|

※AIS2100 Design Principle

Designed for applications in laboratories and industrial sites, AIS1200 is small, light and portable, yet guarantees highly accurate measurement.

AIS2100 offers real-time measures of depth over continuous load and immediate on-site evaluation of various properties through AIS2100 software installed on the analyzer computer with load-depth curves.

AIS2100 evaluates tensile properties very effectively for specimens that are difficult to manufacture because the test subject is small and has a complicated shape. Moreover, AIS2100 enables uniaxial tensile testing of materials with tensile properties that are unevenly distributed. AIS2100’s light weight makes it easily portable for on-site experiments, and it uses a strong adhesive device to prevent Causing damage to subjects of various shapes.

※AIS2100 Hardware Features

- High Accuracy and Reliability

- Enables tests within various ranges with high resolution using a high-capacity loadcell

- Allows adjustments in 0.1 μm units using linear scale for accurate testing.

- Enhanced User Convenience

- USB system connection

- Wired or wireless communication and control modules

- Control and analysis from laptop computer with dedicated software

- Can be operated with portable battery (up to 10 hours)

- Convenient and Stronger Adhesive Device

- Wide dovetail slider enables multiple experiments with single installation

- Highly portable for quick and easy installation

※AIS2100 Instrumented Indentation Test (IIT)

llT as domestic standards including KS B0950, KS B0951, and KEPIC MDF A370.

IIT was newly developed in Korea and meets KEPIC code 2007 and ISO/TR 2008 that were established in 2000. Thanks to its ISO/TR certificate, IIT is drawing a great deal of attention from around the world.

- Range of Properties Evaluation with IIT

- Applies to metals such as general carbon steel, aluminum alloy, SUS series and high-strength steel

- Classified into four groups (Type 1 ~ Type 4) to enhance the accuracy of results

- Allows on-site testing without damaging the subject, which is inserted with a pressure of approximately 150 um

- Simple test preparation and procedures even for novice operators

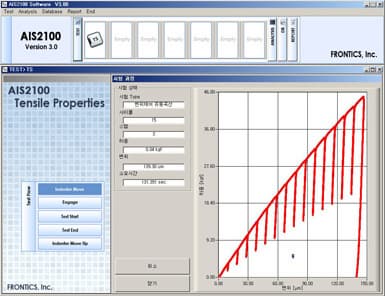

※AIS2100 V3.0 Software

- User-friendly Software

- Reduced Test Steps: Existing 6-step test sequence is reduced to 5 steps

- Test procedures are controlled according to a preconfigured sequence, minimizing potential errors that can be caused by an inexperienced user

- Unnecessary options removed: Tautological parts were removed from automatic application of basic and repeated test conditions.

- Comprehensive Analysis

- More types of subjects can be analyzed, including BCC-type metals (Type 1), FCC-type metals (Type 2), high-strength materials (Type 3) and user-defined materials (Type 4)

- Some analysis options were removed: Now analysis is performed based on the selection of materials by applying the IIT theory that is necessary to classify materials based on analytical results

- Multi-file analysis: Batch processing of multiple sets of data obtained from repeated tests

- Suggestion of methods for material classification for on-site and novice user: Direct and indirect identification using magnetic method and test data, respectively

- All-in-One Software

Includes functions for testing, analysis, database, and creating reports

- Facilitates novice users by minimizing the test operation

- Swift on-site operation based on batch processing of multiple sets of test data

- Allows user to create database and write a report regarding test results

- Prompt comparison of test data and analytical results

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- kwangho Kim

- Address

- Gasan-dong, Byucksan Digital Valley 6-cha,Suite 407, Geumcheon-gu, Seoul, Korea

- Product Category

- Other Measuring & Gauging

- Year Established

- 2000

- No. of Total Employees

- 1-50

- Company introduction

-

FRONTICS is a specialized company in “Material Properties Test Equipment” founded in September, 2000. Based on research results accumulated for a long time, we have developed and supplied assessment devices for properties and residual stress of various structures and materials coping with the demand of industrial and public institutions. FRONTICS AIS series of nondestructive inspection machines. Using the instrumented Indentation Technique (IIT), these machines can test tensile strength, residual stress and fracture toughness of materials from micro/nano dimensions to large metal structures. FRONTICS nondestructive inspection machine can prevent industrial accidents, ensure compliance with government and technical standards, save time and money with on-site testing, and reduce the manufacturing cost of structures.

- Main Product

South Korea

South Korea

,_Smartphone_dryer,_heating_mobile_2.jpg)