Filter Element

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- South Korea

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- auto filter, filter element, filter paper

- Category

- Air Filters & Intakes

Sung Kyung Co Ltd

- Verified Certificate

-

17

| Product name | Filter Element | Certification | - |

|---|---|---|---|

| Category | Air Filters & Intakes | Ingredients | - |

| Keyword | auto filter , filter element , filter paper | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | South Korea | Stock | - |

| Supply type | - | HS code | - |

Product Information

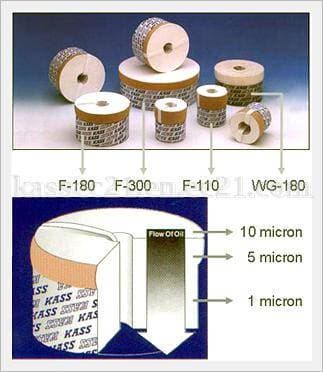

Filter Element

│ FEATURES │

It is the special manufactured filter paper by the unique method of KASS through the strict selection of the pulp, the pure vegetable cellulose fiber that contains plenty of hydrophilic hydroxyl.

Various debris such as metal wear particle, carbon, oxidant, moisture, powder are generated and flowed in during the machinery operation. The debris is passed through the upper element and filter layer of 110mm and pollutants in 0.1µ or bigger and moisture is removed through the deep bed filter and absorption processes.

The air barrier is created by the oil that flows into the filter papers from the element of the roll. This air barrier prevents the passing of oil through the filter paper. Passing through the filter paper, the contaminated oil is flow down to the lower part. During the process, the pollutant and moisture are completely removed through the repeating filtration process.

│ OPERATION │

- Open the IN-OUT valve counter-clockwise completely.

- Shut off clockwise the control valve completely.

- After shutting the darin valve off clockwise and completely, set the starting switch on "ON".

- After the pressure goes up, adjust the pressure at an adequate level with the control valve. (adequate pressure: 1-5kg/cm²)

- If the pressure exceeds 5.5kg/cm², the pump working will be stopped.

- The timer will be working when turning the toggle switch on the control panel to "ON".

- If turning the toggle switch of control panel to "OFF", the timer will not work, but the filtering will be operating continuously. - The following check should be done in case working is stopped by conditions stated above(5);

- Check for any clogging on the element.

- Check for any clogging with alien substances in the suction pipe. - After confirming as shown above (6) and solving the problem, then turn the starting switch to "ON".

│ HOW TO PERFORM MAINTENANCE │

- Clean often the suction strainer after use.

- Avoid idle running for a long time as it may cause to arise some problems.

- In case of sudden decrease the pressure, clean the suction strainer immediately.

│ EXCHANGE OF ELEMENT │

After isolating the IN hose from the lubricating oil tank, turn off the power after discharging lube oil in the housing by idle revolution for a while.

When exchanging the element, release the T-bolt on top while stopping operation.

After opening the cap, take out the used element and insert a new one.

It is important to maintain the state of close contact between the bottom of the element and housing at that time, thus press it from the top position.

After finishing insertion of element, check carefully the O-ring of the cap and shut off T-bolt.

When exchanging the element, adjust the exchange period according to the state of oil.

It is possible to confirm the condition of machines by the state of filter element, when the symptoms are as follows;

A. Case of mixed moisture

- Symptom : there are cracks on the center of element.

- Solution : repair the leak point and change with new element.

B. Case of finding out the metal powder

- Symptom : there is some metal powder on the top of element.

- Solution : Detect the worn out point by confirming the kind of metal powder and after solve the problem by changing the element with a new one.

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- PARK,WON-TAE

- Address

- 301-203 Bucheon Technopark,345, Seokcheon-ro, Ojeong-gu, Bucheon-si, Gyeonggi-do, Korea

- Product Category

- Air Filters & Intakes,Water Treatment

- Year Established

- 1992

- No. of Total Employees

- 1-50

- Company introduction

-

From the foundation of 1992, Sung-Kyung System has accumulated technology in the oil pressure machinery industry of the main equipment in industrial fields.

Sung-Kyung System believes that our important cores in the oil pressure machinery industry are the raise of economical efficiency and the improvement of productivity by reuse of resources. To realize those, Sung-Kyung family work hard for development of new products, quality improvement of products, and elevation of customer service.

Especially, our core technology department consists of experts who have the know-how in the oil pressure, machinery, electric, and electronic industries. Based on their know-how and expertise, we succeed to make the unification of all processes which is the design, manufacture, and installation of industrial oil filter.

From our experiences over the decade, Sung-Kyung System are providing better service to our customers by developing total customer service program and applied total customer service process of diagnosis of working sites, installation/operation, and post-sale management.

Persisting our honesty and dignity of artisans, Sung-Kyung System has produced excellent products to meet our customers' need for over decade since the foundation of our company. The fundamental ideas of our company are the improvement of international competitive power of our customers and the creation of additional value of the customers. Based on these ideas, we have produced KASS oil filter in the oil pressure machinery industry. Now we can proudly say that we have improved the productivities and contributed the environmental conservation....

- Main Markets

-

China

China

Thailand

Thailand

Viet Nam

Viet Nam

- Main Product

South Korea

South Korea