Vibro Breaker - DBB SERIES

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- Category

- Construction Machinery Parts

Daedong Engineering Co., Ltd.

- Verified Certificate

-

12

| Product name | Vibro Breaker - DBB SERIES | Certification | - |

|---|---|---|---|

| Category | Construction Machinery Parts | Ingredients | - |

| Keyword | - | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | - |

Product Information

Introduction

- Upgraded impact power from Vibro Ripper

- Breaking, ripping and gathering at the same time

- Straight line guide system

- Workable in extreme weather condition (-40°C ~ +60°C)

- Proven durable vibration device

Features

- Breaking, ripping and gathering all sort of rocks are available (except hard stone)

- Realized powerful impact by "straight line guide system" . others "arc line guide system"

- Compared with air shock absorber, cushion elastomer is workable in the extreme weather condition (-40°C ~ +60°C)

- Proven durable vibration device with 20years vibration experiences & approved in the world

- Specially designed elastic link absorber protect excavator from vibration shock

- Remarkably reduced shock : Only 30% compared with the existing rippers

- Easier and quicker replacing

- Low maintenance cost (twice longer life time)

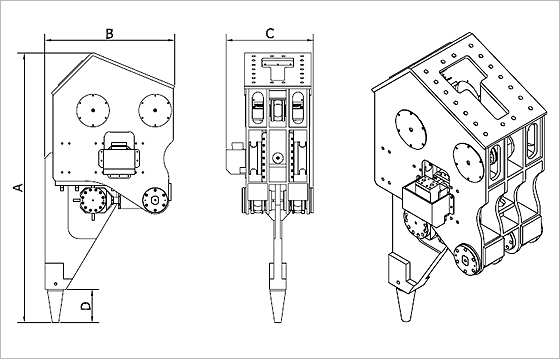

Specification

| Model | Units | DBB150 | DBB200 | DBB350 | DBB600 | DBB700 | |

| Frequency | Vpm | 1500 | 2000 | 2000 | 2000 | 2000 | |

| Max. Hydraulic Pressure | kg/cm2 | 160 | 200 | 210 | 220 | 220 | |

| psi | 2276 | 2845 | 2987 | 3129 | 3129 | ||

| Oil Quantity | l/min | 48 | 80 | 160 | 220 | 252 | |

| gpm | 13 | 21 | 42 | 58 | 67 | ||

| Dimension | Height (A) | in | 45 | 50 | 95 | 101 | 118 |

| mm | 1140 | 1270 | 2410 | 2554 | 2995 | ||

| Length (B) | in | 28.3 | 31.7 | 41.3 | 48.4 | 54.8 | |

| mm | 720 | 805 | 1050 | 1230 | 1393 | ||

| Width (C) | in | 20.1 | 22.4 | 31.5 | 32.6 | 37 | |

| mm | 510 | 570 | 800 | 828 | 940 | ||

| Tooth (D) | in | 9.8 | 10.6 | 12.4 | 12.4 | 12.4 | |

| mm | 250 | 270 | 315 | 315 | 315 | ||

| Main Body Weight | lb | 1058 | 1433 | 4850 | 5512 | 6393 | |

| kg | 480 | 650 | 2200 | 2500 | 2900 | ||

| Applicable Excavator | Ton | 5~8 | 12~17 | 18~30 | 28~36 | 36~42 | |

* Materials and specifications are subject to change without prior notice

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Jung-yeol, Park

- Address

- 802, Dongmoon Tower 1, Baekseok-dong, Ilsandong-gu, Goyang-si, Gyeonggi-do, Korea

- Product Category

- Construction Machinery Parts,Other Hydraulics Tools

- No. of Total Employees

- 1-50

- Company introduction

-

Daedong "Vibro Hammer Series", as the very first Korean (hammer) vibration technology product , was developed with continuous our R&D efforts as the five companies in the world together with Japanese, Dutch, French and German vibrating technology developer, and now grown to products, occupying 95% of the domestic market share and recognized in more than 20 countries in the world.

Deadong Engineering's continuous development for its product enforced excellence in safety and quality by successfully satisfying CE certification and ISO9001 product certification, while also try to meet the consumer's desired criteria in dynamic European market.

The pile driver series (Vibro Hammer) for excavator which used representatively in the construction of temporary work and earth work provides increased mobility and efficiency while reducing the maintenance costs and for this exceptional reason, the pile driver series (Vibro Hammer) is much widely used than the existing crane hammer.

Ultra low-noise vibration ripper is the world's very first new concept ripper which developed and designed to use ultra high-frequency vibration for breaking rock and ripper operation. Ultra Low Noise Vibration Ripper was introduced in 2010 Munich Bauma Expo and drawn an attention of many buyers from all over the world.

Auger Vibro Hammer, which presents an innovative direction of general type of auger drill, is able to perform driving, extracting and arranging extracted sheet piles, H-beams and tubes much better and more efficiently than the general type of auger drill. This new product enables the construction site to do multi task performance with just one machine.

Since the time of Establishment, we have focused and specialized on vibration construction machinery development and successfully built up innovative know-how in vibrating technology.

Thank you very much .

CEO JeongYel, Park

- Main Product

Related Products

HEAVY EQUIPMENT SPARE PARTS(DOOSAN/HYUNDAI/VOLVO/KOMASU/ETC)

HYUNDAI/HALLA/DOOSAN/SAMSUNG/ETC FORKLIFT SPARE PARTS

DTH BIT

Cummins engine parts

CATERPILLAR EXCAVATOR SPARE PARTS

South Korea

South Korea