Compressoion Spring

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- Category

- Other Machinery Parts

- Country / Year Established

-

South Korea

/

South Korea

/

- Business type

- Others

- Verified Certificate

-

17

| Product name | Compressoion Spring | Certification | - |

|---|---|---|---|

| Category | Other Machinery Parts | Ingredients | - |

| Keyword | - | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | - |

Product Information

Overview

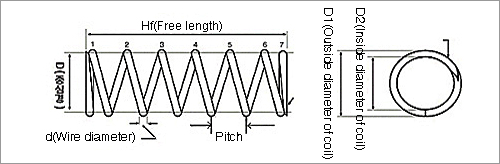

- Compression spring is the most commonly used spring. It is easy to design, relatively simple and cheap to manufacture, and has higher efficiency. It has various shapes such as cylindrical, hourglass, barrel etc depending on the application

Application

- Components for automobile, electrical, electronic, stationery, toy, industry, and information - communication

Features

- Compression coil spring is typically cylindrical and manufactured by hot or cold coiling, and the material for compressing the load applied to the spring. Spring ends have different shape according to the types of load and the coil diameter depends on the size.

Symbols and formula used for compression spring design

1) Spring symbols

|

d

|

wire diameter

|

ai

|

arm length (mm)

|

|

|

Da

|

mean coil diameter

|

a2

|

arm length (mm)

|

|

|

Na

|

number of active coils

|

E

|

||

|

Nt

|

total number of coils

|

G

|

||

|

K

|

spring constant (kg / mm)

|

C

|

spring index (Da/d)

|

|

|

P

|

Load (kg)

|

G

|

SWP

|

8,200

|

|

d

|

deflection (operation angle) (mm)

|

SUS

|

7,500

|

|

|

Pj

|

initial tension

|

Phosphor bronze

|

450

|

|

|

Kt

|

arm spring constant (kg.mm/degree)

|

E

|

SWP

|

21,000

|

|

M

|

moment (kg.mm)

|

SUS

|

19,000

|

|

|

q

|

torsion angle

|

Phosphor bronze

|

11,000

|

|

|

K1

|

stress correction coefficient

|

P

|

SWP

|

7.85

|

|

Ke

|

arm spring stress correction coefficient

|

SUS

|

7.9

|

|

|

|

torsion stress(kg/mm2)

|

brass

|

8.6

|

|

|

O'

|

bending stress (kg/mm2)

|

Geman silver

|

9.0

|

|

|

|

tensile strength(kg/mm2)

|

Phosphor bronze

|

8.1

|

|

|

ℓ

|

length of spring with force applied (mm)

|

inconel

|

8.25

|

|

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

Related Products

Vagcom 17.1.3 ATMEGA162 VCDS 17.1.3 China crack VAG 17.13 Fo

All in one POS SYSTEM

OSTEOTOMES

JS-2EJ4

yacht fittings