E.P (Electrostatic Precipitator)

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- Category

- Air Cleaners & Parts

Sejin Electronics Co., Ltd.

- Verified Certificate

-

16

| Product name | E.P (Electrostatic Precipitator) | Certification | - |

|---|---|---|---|

| Category | Air Cleaners & Parts | Ingredients | - |

| Keyword | - | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | - |

Product Information

Electrostatic Precipitator(SA-30)

This electronic dust collector is installed and used for cleaning the air in places where smoke or odor is generated from lasermarking, soldering, or cigarette smoking. The product is very effective if it isinstalled in a relatively narrow place where ventilation space is small.

Introduction

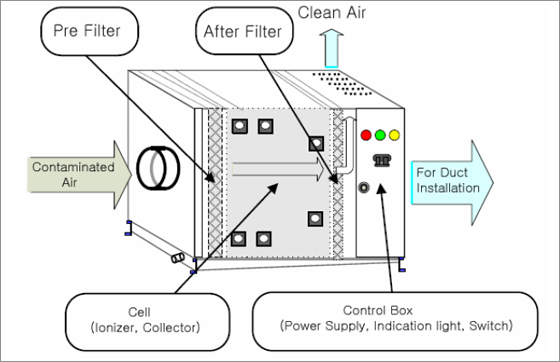

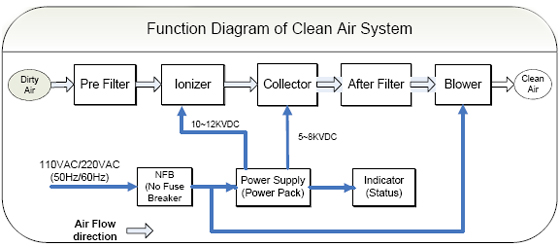

Clean Air System (E.P, Electrostatic Precipitator) is based on principle of electrostatic. E.P makes contaminated particles to be electrostatic materials and to be collected. Clean Air System is structured by Pre Filter, Cell and After Filter.

Cell is organized the Ionizer and the Collector. So what is called Two Stage charge. The function of Pre Filter filters large contaminated particles. At ionizer, it makes contaminated particles to ionize by corona discharge which is applied high voltage (DC 10 ㎸ ~ 12 ㎸), and then ionized particles is collected at collector.

High voltage (DC 5 ㎸ ~ 7 ㎸) is supplied to Collector which is plate collected at regular distance. more than 0.01 µm contaminated particle collected at Collector. At the same time, After Filter makes clean air coming out and prevents collected particle from coming out. Clean Air System has benefit to filter 0.01 µm particles. The ratio of efficiency is more than 97%.

Special Features of Clean Air System

- Elimination of cigarette, particles and all sorts of harmful smogs

(Elimination of particles less than 0.01 µm,efficiency ratio more than 97%) - Removal of all sorts of machinery contamination

(CNC, grinding and welding) - Removal of stink, noxious gases, all sorts of deodorization

- Built-in Protection Function (Over-current, Over-voltage)

- Easy maintenance (Cleaning and replacement Filter and Cell)

- Built-in Warning indicator (POWER, NORMAL, TROUBLE)

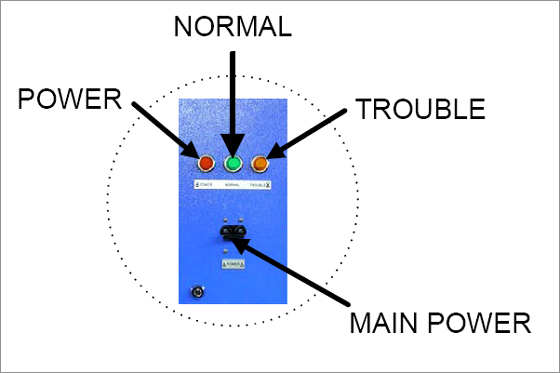

Description of Control box

| Description of Control box | Function |

| MAIN POWER | Switches the Systems On and OFF In case of switch "ON" , Power supplies to POWER PACK and BLOWER. Spec. : NFB(NO FUSE BREAKER) |

| POWER Lamp | Illumination RED light When "MAIN POWER" SW is "ON" position. |

| NORMAL Lamp | Illumination Green light When the system is in operation. Green light is "OFF" when the system does not work properly. |

| TROUBLE Lamp | Illumination Yellow light When the system is in trouble. Yellow light is "OFF" when the system is in operation. |

Specification

| Model | SA-30 |

| Air volume (CMM/min) | 30 CMM |

| Noise level (dB) | 68dB |

| Efficiency (%) | 97% |

| Power Supply (AC) | 220VAC/60Hz / 1Ø |

| Power Consumption (W) | 345W |

| Dimension (W x D x H) (mm) | 830 x 594 x 530 mm |

| Weight (kg) | 60kg (approx) |

Function Diagram

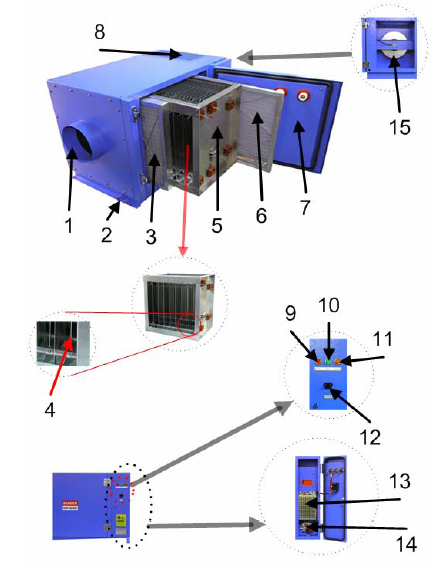

Part List of Product

| Position | Description | Q'ty | Refer |

| 1 | INLET | 1 | |

| 2 | DRAIN OUTLET | 1 | |

| 3 | PRE FILTER | 1 | |

| 4 | IONIZER | 1 | |

| 5 | COLLECTOR | 1 | |

| 6 | AFTER FILTER | 1 | |

| 7 | DOOR | 1 | |

| 8 | OUTLET | 1 | |

| 9 | SIGNAL LAMP (Red) | 1 | POWER "ON" Condition |

| 10 | SIGNAL LAMP (Green) | 1 | NORMAL Condition |

| 11 | SIGNAL LAMP (Yellow) | 1 | TROUBLE Condition |

| 12 | "MAIN POWER" SW | 1 | NFB (No Fuse Breaker) |

| 13 | POWER PACK | 1 | Power Supply |

| 14 | TERMINAL BLOCK | 1 | |

| 15 | BLOWER | 1 |

Installation

- Caution

- Make sure power and earth line is connected correctly in the Control Box When the system is installed. - This unit is equipped with a three-prong (grounded) plug for your protection against shock hazards and should be plugged directly into a properly grounded three-prong receptacle. DO NOT, UNDER ANY CIRCUMSTANCES, CUT OR REMOVE THE GROUNDING PRONG FROM THIS PLUG.

- Do install the system by a skilled craftsmen.

- The Clean Air System is inspected and tested before shipment. the operating company can be installed only connection between power, earth line and terminal block in the control box.

A. Make sure "MAIN POWER" SW switches "OFF" position.

B. Must use the approved power and earth cable when the System is installed.

Operation

- Caution

-Because Safety Door SW is installed, Power should be turned off when the System Door is open in operation - 1. Check list before operation the unit

- a) "MAIN POWER" SW is located "OFF" position.

- b) Make sure electrical connection in the Control Box is wired correctly and

connecting condition is good visually.

- c) Make sure the Cell(Ionizer, collector) is cleaned, no damaged mechanical parts visually.

- d) Make sure the electronic cell is properly placed in the cabinet-airflow direction on the plate should be pointing toward the fan.

- e) Make sure that the air inlet and air outlet, cover are securely in place.

- f) Electronic air cleaners should NOT be placed in any area where potentially dangerous gasses or vapors exist, nor should they be used in wet environment. - Operation Procedure

- a) "MAIN POWER" SW switched "ON" position.

- b) Conform indication light is below listed in normal operation.

- c) Conform air flow direction of Blower

(Air flow direction comes out in normal operation) - Procedure of abnormal operation

- Check the next procedure when the light is not indicated above listed in operation.

- a) "MAIN POWER" SW switches "OFF" position.

- b) Check the corrected electrical connection of power and earth line.

- c) Check the mechanical parts and contamination degree of Cell(Ionizer, Collector).

Maintenance

- Caution

- Inspect Pre Filter, Cell, After Filter and Blower to check the degree of contamination at least once a week.

- No damage mechanical parts (Collector Plate, Ionizer Wire, Filter, Blower, and so on) during cleaning process

- After cleaning, Reinstall Cell and H.V(High voltage) Insulator in the dry condition.

- Before reinstalling the Cell, check the contacts at the door for cleanliness and conductivity. - Use skilled maintenance agents for cleaning.

Use proper detergent for cleaning. - Turn off and unplug air cleaner before opening door to remove electronic cell and pre-filter for cleaning. Always be careful when handing the electronic cell. Sharp edges and wires are capable of inflicting wounds. Care should also be taken when cleaning because of extremely hot water and potentially harmful effects of detergents on your skin.

- a) Use soft brush to clean Filter and Cell with proper cleaning detergent.

b) Rinse the Cell After cleaning especially.

c) Remove moisture of mechanical parts with air compressor.

d) Reinstall the Cell only in the dry condition.

Appendix

Description of key Parts

| Part | Material | Dimension (Width x Height x Depth) |

| Pre Filter | AL 1.5t | 360 x 360 x 20(mm) |

| Ionizer | tungsten wire | Ø0.1 (mm) |

| Collector | AL 2.0t | 465 x 465 x 360 (mm) |

| After Filter | AL 1.5t | 360 x 360 x 45 (mm) |

| Insulator | FRP | 50 x 50 x 15 (mm) |

| Power Pack | Steel 1.5t | 145 x 80 x 155 (mm) |

You can choice ionizer part, the wire or saw type.

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- JUNG, DONG-HYOP

- Address

- 489-6, KALHYON2-DONG, EUNPYONG-KU,SEOUL

- Product Category

- Electrical Equipment

- Company introduction

-

We, Sejin Electronics Co., Ltd. have developed and produced the H.V. Power Supply, Ionizer, E.P. and Power Pack since our establishment in 1991. We currently manufacture the direct current high voltage generator. In 2003, we were ISO 9001/ KSA 2001 certified, which has equipped us to renovate the level of our quality. Also, we assure our customers satisfaction, based on our ample experience, state-of-the-art technology and our philosophy in customer-oriented service, MBO and creatier spirit. Executives and Staffs of Sejin Electronics Co., Ltd.

- Main Product

South Korea

South Korea

_2.jpg)