Concrete Block Machines GOLD-2010/700

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- Category

- Other Machinery & Industry Equipment

Harex Engineering Co., Ltd.

- Verified Certificate

-

17

| Product name | Concrete Block Machines GOLD-2010/700 | Certification | - |

|---|---|---|---|

| Category | Other Machinery & Industry Equipment | Ingredients | - |

| Keyword | - | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | - |

Product Information

Block Machine Gold-2010/Gold-700

|

Models

|

SILVER-530

|

SILVER-660

|

SILVER-850

|

SILVER-900

|

GOLD-700

|

GOLD-2010

|

||||||

|

Pallet size (mm)

|

530 x 530 x 6

|

660 x 530 x 9

|

850 x 530 x 9

|

900 x 900 x 12

|

1,400 x 700 x 14

|

1,400 x 1,300 x 16

|

||||||

|

Effective area (mm)

|

500 x 500

|

630 x 500

|

820 x 500

|

860 x 860

|

1,250 x 650

|

1,300 x 1,250

|

||||||

|

Product height (mm)

|

60-200

|

60-200

|

60-200

|

60-200

|

60-200

|

60-200

|

||||||

|

Vibrator (no.)

|

2

|

2

|

2

|

2

|

4

|

4

|

||||||

|

Motors for vibration

|

7.5 kW x 2

|

22 kW x 2

|

15 kW x 2

|

18.5 kW x 2

|

30 kW x 2

|

45 kW x 2

|

||||||

|

Production capacities

|

Per pallet

|

|||||||||||

|

Output per hour

|

Output per hour

|

Output per hour

|

Output per hour

|

Output per hour

|

Output per hour

|

|||||||

|

Block 390 x 190 x 100 mm (4")

400 x 200 x 100 mm |

4

|

960-1,20

|

5

|

1,200-1,500

|

7

|

1,680-2,100

|

14

|

3,360-4,200

|

10

|

2,100-2,400

|

33

|

6,930-7,920

|

|

Block 390 x 190 x 150 mm (6")

400 x 200 x 150 mm |

3

|

810-900

|

4

|

1,080-1,200

|

5

|

1,350-1,500

|

10

|

2,700-3,000

|

7

|

1,470-1,680

|

21

|

4,410-5,040

|

|

Block 390 x 190 x 190 mm (8")

400 x 200 x 200 mm |

2

|

600

|

3

|

900

|

4

|

1,200

|

8

|

2,700-3,000

|

6

|

1,260-1,440

|

18

|

3,780-4,320

|

|

Paver UNI 225 x 112.5 x 60 mm

Without face mix With frace mix |

8

8 |

1,920-2,160

1,440-1,680 |

10

10 |

2,400-2,700

1,800-2,100 |

12

12 |

2,880-3,240

2,160-2,520 |

18

18 |

4,320-4,860

3,240-3,780 |

25

25 |

6,000-6,750

4,500 |

50

50 |

12,000

7,500-9,000 |

|

Paver Rect. 200 x 100 x 60 mm

Without face mix With face mix |

8

8 |

1,920-2,160

1,440-1,680, |

12

12 |

2,880-3,240

2,160-2,520 |

14

14 |

3,360-3,780

2,520-2,940 |

28

28 |

6,720-7,560

5,040-5,880 |

33

33 |

7,920-8,910

5,940 |

60

60 |

14,400

9,000-10,800 |

|

Curbstone A(1) with face mix

|

3

|

270

|

5

|

450

|

||||||||

|

Curbstone B(2)with face mix

|

2

|

180

|

4

|

360

|

||||||||

|

Curbstone C(3)with face mix

|

2

|

180

|

4

|

360

|

||||||||

|

Curbstone SA(4)wo/w face mix

|

4

|

720/480

|

7

|

1,260/840

|

||||||||

|

Curbstone SB(5)wo/w face mix

|

3

|

540/360

|

6

|

1,080/720

|

||||||||

|

Curbstone SC(6)wo/w face mix

|

3

|

540/360

|

6

|

1,80/720

|

||||||||

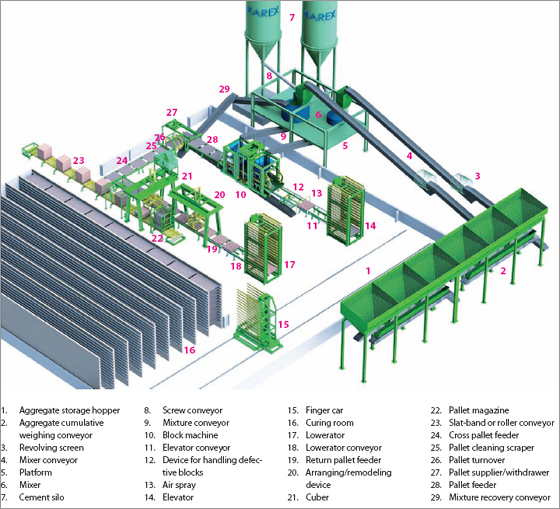

The GOLD model machines are stationary, universal concrete block machines for large-scale production of light-weight and dense concrete products: bricks, hollow and solid blocks, pavers with/without face mix layer, curbstones, retaining wall blocks, and other blocks for construction, landscaping, civil engineering and environmental protection

- Heavy-duty machine frame structure with three parts: forming (press) part, base mix filling part and face mix filling part

- Base mix part and face mix part can be attached to and detached from forming part for easy mould change and maintenance.

- Face mix part for double layer concrete units (e.g., pavers, curbstones)

is optional and can be retrofitted. - Complete block making plant with equipment for batching and mixing, block forming, transport (elevator and lowerator, finger car, etc.) and cubing

- Four main shaft and sliders

- Proportional control valve that can control hydraulic speed via control touch-screen

- Filling box is freely suspended, so vibration is not transmitted to filling box.

- Hydraulic/electrical device for lifting/lowering filling box

- Agitators to facilitate filling of material into mould

- Integrated vibration table with four vibrators driven by high-efficiency inverter motors (servo motors optional)

- Centrifugal force of vibrators can be easily adjustable, and rpm can be infinitely variable.

- Mould mounting by pneumatic air-bag clamping system allows quick mould change.

- Oil heater, oil cooler, oil tank ventilator, oil temperature indicator, oil level indicator, oil filter

- Control with touch screen for easy menu selection, data input and modification

For Convenience Sake

- Various equipment, standard or optional, to enhance and facilitate block production

- Pallet supplier/withdrawer (option)

- Air spray

- Device for handling defective blocks

- Pallet scraper and pallet turnover

Moulds

- Moulds of high precision and long life

- High precision: Design by CAD, CNC-machining, and strict quality control ensure precise dimensions of moulds.

- Long life: High-quality material and strict heat-treatment ensure long mould life.

- Various moulds for standard or custom-designed blocks

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Jung, Pan-hyup

- Address

- 45, Seongseo-ro 9-gil, Dalseo-gu, Daegu, 704-801, KOREA

- Product Category

- Other Machinery & Industry Equipment

- Year Established

- 1999

- No. of Total Employees

- 1-50

- Company introduction

-

- Main Product

South Korea

South Korea