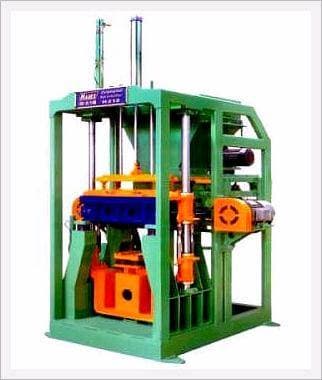

Harex Concrete Block Machine

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- Category

- Other Machinery & Industry Equipment

Harex Engineering Co., Ltd.

- Verified Certificate

-

17

| Product name | Harex Concrete Block Machine | Certification | - |

|---|---|---|---|

| Category | Other Machinery & Industry Equipment | Ingredients | - |

| Keyword | - | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | - |

Product Information

Feature

Harex H-212 concrete block machine is robust, verstile, very compact and very economical. It is capable of producing concrete bricks, hollow and solid blocks and paving stones.

- Robust, compact and trouble free

- Highly cost-effective

- Perfect choice for start-up

- Formed blocks can be handled easily by hand; no need for handling equipment

Structure

- The machine frame is a sturdy structure made of section steel.

- Wear-resistant slide bushings are used in the sliding metal bearings of the guide pillars that guide the moving of mould and compaction head.

- Double-sliding metal bearings are mounted on two guide pillars so that mould and compaction head move smoothly without error.

Filling System

- Filling box moves by means of powerful hydraulic cylinder with shock-reducing device, and its speed can be adjustable by valve.

- Impeller, a device driven by geared motor to facilitate the filling of material into mould

Block Machine

- Two special vibrators (2.2 kW x 2 = 4.4 kW)

- Pallet size: 450 x 250 x 4.5 mm (steel) or 450 x 250 x 60 mm (wooden)

- Block height: 60 - 200 mm

Compaction

- Mould is mounted to the compaction frame by means of screw joint.

- Adjustable pressure adjustment valve

Hydraulic Device

- Oil pump and driving part including motor are installed separately.

- Pilot valve

- Two pressure selection stages are available for cylinder operation.

- Includes necessary piping and valves

- Oil tank ventilator, oil temperature indicator, oil level indicator, oil filter for preventing contamination

- Oil heater is installed on the hydraulic tank.

- Oil cooler is installed on the pipeline through which oil returns to the tank. A compulsory ventilation fan controlled by temperature sensor is also installed. A separator oil pump is installed on the oil cooler.

Specifications

|

Pallet size |

450 x 250 x 4.5 mm (steel) or 450 x 250 x 60 mm (wooden) |

|

Effective area |

400 x 200 mm |

|

Block height |

60 - 200 mm |

|

Machine height |

Approx. 2,200 kg |

Production Capacities

| Blocks & Size (mm) | Per Mould | Per Cycle | Per Hour | |

|

Brick |

190 x 90 x 57 (Korea) | 12 | 6 | 4,320 |

|

215 x 100 x 65 (Malaysia) |

12 | 6 | 4,320 | |

|

Block |

390 x 100 x 190 |

2 | 5 | 600 |

|

390 x 150 x 190 |

1 | 5 | 300 | |

|

390 x 190 x 190 |

1 | 5 | 300 | |

|

Paver |

UNI |

3 | 5 | 960 |

|

Curbstone |

Type A |

|||

|

Type B |

||||

|

Type C |

||||

|

Type SA |

||||

|

Type SB |

||||

|

Type SC |

||||

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Jung, Pan-hyup

- Address

- 45, Seongseo-ro 9-gil, Dalseo-gu, Daegu, 704-801, KOREA

- Product Category

- Other Machinery & Industry Equipment

- Year Established

- 1999

- No. of Total Employees

- 1-50

- Company introduction

-

- Main Product

South Korea

South Korea

,_Smartphone_dryer,_heating_mobile_2.jpg)