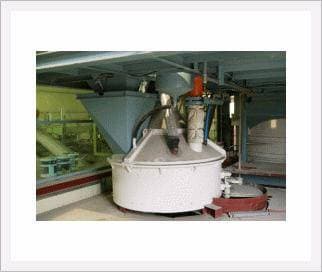

Harex HPM Pan Mixers

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- Category

- Other Construction Machinery

Harex Engineering Co., Ltd.

- Verified Certificate

-

17

| Product name | Harex HPM Pan Mixers | Certification | - |

|---|---|---|---|

| Category | Other Construction Machinery | Ingredients | - |

| Keyword | - | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | - |

Product Information

Feature

Harex HPM pan mixer with vertical axles and coaxial motor allows rapid performance in dry, semi-dry and wet mixing for all types of concrete.

Powerful Mixing

- The pan mixer is equipped with vertical axles and coaxial motor which are mounted on the mixing pan of wide diameter. This allows a low thickness of material to be mixed and, thus, the advantage of shorter mixing time and higher quality of mix.

- The mixing pan is made of substantially thick steel plate.

- The bottom and wall of the mixing pan are fitted with replaceable wear-resistant alloy steel linings.

- Material discharge is extremely rapid via a circular discharge door operated by a hydraulic ram.

- The mixing pan is sealed with gaskets of polyurathane resin.

Reliability and Versatility

- The mixer is preset to be fitted with any automatic water-dosing system.

- Moisture probes and water sprayers are fitted to allow rapid water absorption.

- A wide range of accessories can be mounted on the mixer to meet the customer's requirements. For example, up to 3 discharge gates (total, partial and emergency opening) can be fitted. In addition, other accessories like admixture dispenser, automatic water-dosing system, steam equipment, dust suction and collection equipment, and air bag can also be fitted.

Simple Maintenance and Safety

- The internal mixer cleaning is easy thanks to the wide pan covers.

- Pan mixer covers are fitted with both mechanical and electric safety switches.

Efficiency of Mixing

- Extensive study and test on the rotation and revolution speeds of the blades allow a high performance without causing segregation among materials of different sizes and types.

- The gearbox turns on a wide diameter disc gear, allowing silent and movement-free rotation even in heavy-duty conditions.

- The material movement inside the mixing pan is malleable, progressive and continuous.

- After only one complete rotation, the blade movement completely covers the whole surface of the mixer unit.

Specifications

| Unit | 500/330 |

750/500 |

1125/750 |

1500/1000 |

2250/1500 |

2250/1500S |

3000/2000 |

|

|

Input (Loading) |

liter | 500 | 750 | 1,125 | 1,500 | 2,250 | 2,250 | 3,000 |

|

Output |

liter | 330 | 500 | 750 | 1,000 | 1,500 | 1,500 | 2,000 |

|

Average time per cycle (mixing + discharge, excluding loading time) |

sec. | 45 | 45 | 45 | 45 | 60 | 45 | 60 |

|

Star) |

no. | 1 | 1 | 1 | 2 | 2 | 2 | 3 |

|

Mixing blade |

no. | 2 | 2 | 3 | 2 | 2 | 2 | 2 |

|

Scraper |

no. | 1 | 1 | 1 | 2 | 2 | 2 | 3 |

|

Mixing system speed |

rpm | 16 | 16 | 14.7 | 12.4 | 10.4 | 12.4 | 10.4 |

|

Star speed |

rpm | 48 | 46 | 44.5 | 42 | 35.4 | 42 | 35.4 |

|

Pan mixer power |

kW | 15 | 18.5 | 30 | 45 | 55 | 75 | 110 |

|

Hydraulic unit power |

kW | 2.2 | 2.2 | 3 | 3 | 3 | 3 | 3 |

|

Weight |

kg | 2,500 | 3,000 | 3,700 | 4,800 | 5,500 | 5,600 | 7,500 |

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Jung, Pan-hyup

- Address

- 45, Seongseo-ro 9-gil, Dalseo-gu, Daegu, 704-801, KOREA

- Product Category

- Other Machinery & Industry Equipment

- Year Established

- 1999

- No. of Total Employees

- 1-50

- Company introduction

-

- Main Product

Related Products

Quick Coupler DMQ series

MPSystem Robot Parking - MetroCL

DAEMO Hydraulic Shear DMS360 (Excav. 33~45T)

DTH BIT

Aerial Work Platform - Boom Lift Truck HS380

South Korea

South Korea