QT6-15 full automatic Concrete Paving Block Making machine

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Brand name

- Huali

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

Linyi Huali Machinery Co., Ltd

- Country / Year Established

-

China

/

China

/

- Business type

- Others

- Verified Certificate

-

13

| Product name | QT6-15 full automatic Concrete Paving Block Making machine | Certification | - |

|---|---|---|---|

| Category | Construction Material Making Machinery | Ingredients | - |

| Keyword | block making machine , brick machine , concrete block making machine , paving block making machine | Unit Size | - |

| Brand name | Huali | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | 8479892030 |

Product Information

QT6-15 Full automatic concrete paving block making machine

Characters: PLC intelligent control.Man-machine interface, control system equipped with complete logic control, production program, malfunction diagnosis system and remote control function. So it doesnt need a professional person but only need a simple trainning to the operator.

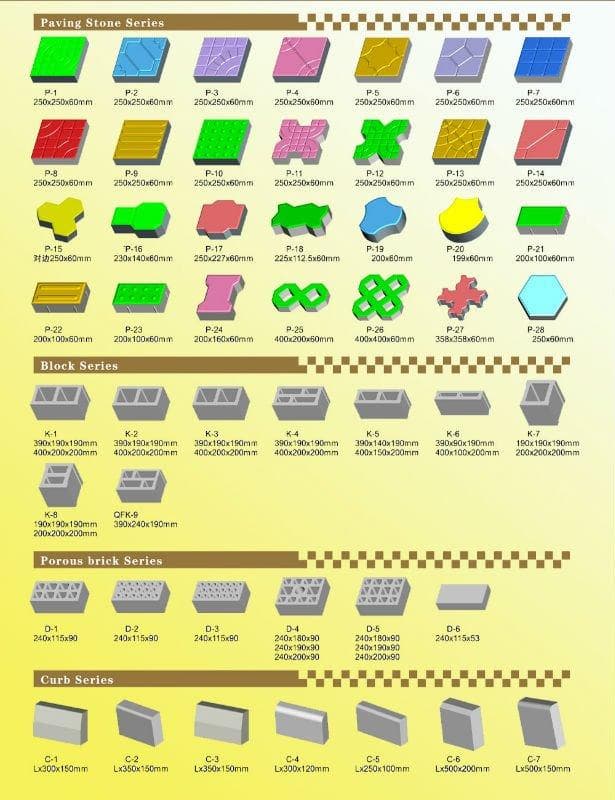

Product scope: It produces various bricks/blocks including color-face bricks (layered material feeding), through-body tiles, dock linkage blocks, road curb bricks,sod bricks, hydraulic blockshollow blocks, perforated bricks, and standard bricks etc.

Optional configuration:

1. Lift-slab Elevating Conveyor (block stacking machine):

According to the different type of bricks, the finished products will be moved from the discharge transmitter and pilled up automatically 3 to 8 layers by the elevating conveyor, and carried to the maintaining place by the fork lifter truck. It could reduce labor and ground.

2. Colour face material feeder (layered material feeding)

Equipped with color face material feeding device, it could make various color face bricks , through-body Environmental protection bricks, road curb rocks, hydraulic blocks and sod bricks and so on.

For QT6-15 Block Forming Machine, intelligence system of PLC is adopted to control, with man-machine interface and automatic diagnosis function. For the electro-hydraulic proportional valve is used in its vibrating system, the materia-feeding with low frequency and the shape-vibrating with high frequency have been achieved. Its material distributing system mounted with multirow of stirring forkscan quickly and evenly discharge the materials into the moulding box. Only by changing its moulds and dies, all kinds of blocks, standard bricks, cellular bricks, grass planting titles, etc. can be manufactured, with an annual production capacity of 50,000 cubic meters ofstandard brick. So, it is one kind of ideal equipment for producing wall materials of new type.

|

Main Technical Specifications |

|

|

Production per Mould: |

6 pcs/mould (Standard Block: 400x200x200mm) |

|

39 pcs/mould (Solid Block: 240x115x53mm) |

|

|

18 pcs/mould (Hollow Block: 240x115x90mm) |

|

|

|

24 pcs/mould (Holland Brick: 200x100x60-80mm) |

|

Cycle Time: |

15-20S seconds |

|

Production per Day (8 Working Hours): |

Hollow Block (400x200x200mm): 11500pcs |

|

Solid Block (240x115x53mm): 57600 pcs |

|

|

Hollow Block (240x115x90mm): 28800 pcs |

|

|

|

Holland Brick (200x100x60-80mm): 28800 pcs |

|

Vibrating Frequency: |

2850 rolls/minute |

|

Vibrating Force: |

80 KN |

|

Motors Power: |

34 KW |

|

Machine Dimensions: |

4900x2000x2700mm |

|

Pallet Size: |

990x850mm |

|

Gross Weight: |

about 13T |

|

Raw Materials: |

crushed stone, sand, cement, dust and coal fly ash, cinder, slag, gangue, gravel, perlite, and other industrial wastes. |

|

Applied Products: |

concrete blocks, solid/hollow/cellular masonry products, paving stones with or without face mix, garden and landscaping products, slabs, edgers, kerbstones, grass blocks, slope blocks, interlocking blocks, etc |

|

Applied Fields: |

widely used in buildings, road pavings, squares, gardens, landscaping, city constructions, etc |

The type QTY6-15A can produce all kinds of hollow blocks and solid bricks and color paving bricks,only by changing different moulds.

QT6-15 hollow block making machine other information:

1. Area: Workshop area: 150-200m2, all factory area 3000m2, the bigger, the better.

2. Workers : 5.

3. Ratio of raw material:cement 8%-10% sand 30%-40% stone:50%-60%,about cement :sand : stone is1:4:5.

4.hollow block weight::

(390*190*190) :17KG,(190*140*190):13.5KG,(390*90*190):10KG

5. raw material consumption per day:150-190T

6. water consumption per day:3%-5% of raw material Weight.

QT6-15 block making machine guarantee:

Our hollow block making machine is of one year guarantee,during the period we could supply spare parts if they are broken.

QT6-15 block making machine production pressure:

Hollow blocks can reach 8-10Mpa,Solid bricks can reach 10-12Mpa,so they have a high pressure,can be used widely.

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Mr.Gao

- Address

- Shengli Development Zone No.77, Tancheng County, Linyi City

- Product Category

- Construction Material Making Machinery,Other Metal & Metallurgy Machinery

- No. of Total Employees

- 101-500

- Company introduction

-

Huali-the best China block making machine supplier, AAC plant and brick machine manufacturer

Website: http://www.hualimachine.com

E-mail: crystal_admin@hualijixie.com;admin@linyihuali.cn

Paving brick machine

Egg laying block making machine

AAC plant

AAC Material operating system

Pouring & Curing System

Cutting system

Autoclave system

Electronic system

Brick Equipment

PLC controller

Block Mold

Block Mixer

Block Forklift

Hand Carts

Hydraulic Station

- Main Markets

-

Brazil

Brazil

Japan

Japan

Poland

Poland

Russia

Russia

Rwanda

Rwanda

Saudi Arabia

Saudi Arabia

Spain

Spain

Sudan

Sudan

Syria

Syria

Tunisia

Tunisia

U.A.E.

U.A.E.

U.S.A

U.S.A

- Factory Information

-

Linyi Huali Machinery Co., Ltd

- Main Product