Activated Carbon

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- Category

- AdsorbentActivated Carbon

Osung Envitech Co., Ltd.

- Country / Year Established

-

South Korea

/

South Korea

/

- Business type

- Others

- Verified Certificate

-

16

| Product name | Activated Carbon | Certification | - |

|---|---|---|---|

| Category | AdsorbentActivated Carbon | Ingredients | - |

| Keyword | - | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | - |

Product Information

Features

Norit is the world's largest producer of activated carbon and related services. With over 80 years of experience, Norit has grown to produce well over 150 different types of activated carbon products, enabling them to offer the most choices, precise fit and best performance for any application. Norit also offers activated carbon reactivation, carbon change out services, and both granular and powdered carbon systems & equipment.

Nowadays Norit activated carbon is a global company, leading the way in purification solutions based on activated carbon technology. Our activated carbons are produced or reactivated in a multitude of factories in the Netherlands, Italy, the United Kingdom and the United States, with company participation in factories in Mexico and Brazil. In steam activated as well as chemical activation we use a wide spectrum of raw materials, such as peat, wood, lignite, coal, coconut shells and even olive pits, to produce a vast array of activated carbon types.

1. Steam Activation Process

The majority of activated carbon used throughout the world is produced by steam activation. Steam activated carbons are produced by a two stage process. Firstly, the material is carbonized and a coke is produced, the pores of which are either too small or constricted for it to be a useful adsorbent. The next stage is a process of enlarging the pore structure so that an accessible internal surface is created. This is achieved by reaching the semi-product with steam between 900˚C and 1100˚C. A feature of the steam activation process is the large dimension of the kilns to allow sufficient residence time for activation because of the relatively slow reaction between steam and carbon. Rotary kilns or multiplehearth kilns can be used. NORIT has a wide experience with both types and is, therefore, in a position to produce activated carbons for all applications in situations where the ultimate in inorganic purity is required. Special acid washed carbons are available.

2. Chemical Activation Process

Chemically activated carbons are produced by mixing a chemical with a carbonaceous material, usually wood, and carbonizing the resultant mixture. The carbonization temperature is relatively low, e.g. 400˚C ~ 500˚C for the NORIT and DARCO range of chemically activated carbon. The chemicals normally used are phosphoric acid and zinc chloride solutions which swell the wood and open up the cellulose structure. However, the use of zinc chloride as an activating agent is decreasing because of the environmental problems that are involved. Further the residual concentration of zinc in the carbon is undesirable in many applications so that the phosphoric acid process is, therefore, preferred. It is used by NORIT to produce the range of chemically activated carbons at its plants in Scotland and Texas.

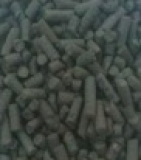

NORIT Activated carbon is a carbonaceous adsorbent with a high internal porosity, and hence a large internal surface area. Commercial activated carbon grades have an internal surface area of 500 up to 1500 m2/g, related to the type of application, two major product groups exist:

- Powered activated carbon; particle size 1 - 150 micron

- Granular activated carbon (granulated or extruded), particle size in the 0.5 - 4 mm range

A proper activated carbon has a number of unique characteristics: a large internal surface area, dedicated (surface) chemical properties and good accessibility of internal pores. According to IUPAC definitions three groups of pores are distinguished:

- Macropores (above 50 nm diameter)

- Mesopores (2-50 nm diameter)

- Micropores (under 2 nm diameter)

Norit offers over 150 different varieties of activated carbon to ensure the precise fit for your application. This precise fit translates into best performance whether it's meeting critical product specifications, using the least amount of carbon to accomplish your task, or getting longer treatment cycles and fewer change outs. While activated carbon may look the same to the naked eye, pore size and structure make a huge difference in how well impurities are adsorbed. This is why Norit has taken the time to test thousands of combinations of raw materials, activation methods, activity levels, and other factors

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Yongmyeon Lee

- Address

- 339-1 Dangha-dong, Seo-gu, Incheon, 404-818, Korea

- Product Category

- Other Business Services

- No. of Total Employees

- 1-50

- Company introduction

-

Welcome !

Welcome to our e-catalog home.

Here you can find information about our products. You can also send us inquiries and post comments about our company and products. We hope you enjoy your visit.

- Main Product

Related Products

Oxyegen absorber packets of various sizes available

Activated Carbon

Adsorbents based on Activated Carbon

VCI Desiccant GVD310

Adsorbents based on Activated Carbon/Oxides