Stretching of Span Yarns Part

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- Category

- Other Machinery & Industry Equipment

- Country / Year Established

-

South Korea

/

South Korea

/

- Business type

- Others

- Verified Certificate

-

13

| Product name | Stretching of Span Yarns Part | Certification | - |

|---|---|---|---|

| Category | Other Machinery & Industry Equipment | Ingredients | - |

| Keyword | - | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | - |

Product Information

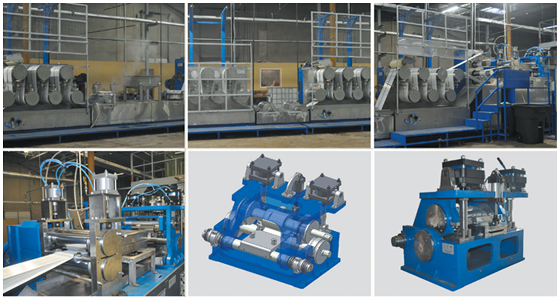

Stretching Part

Stretching of span yarns is an important process as it adds tensile strenght to the yarn property. We have three types of stretching machines as follows.

- SS-3100 First-Stretcher/Second/Third-stretcher

- Many pieces of tows contained into the can starts stretching through a roller with the first stretcher The roller revolves by the gear to minimize noise it maintains a fixed torque between the rollers and prevents slipping and reverse revolution. The stretching roller is plated with anti-corrosive agent. - SS-3200 First-Stretching bath / Second-stretching bath

- Tensile strength yielded in the process of the first stretching is fixed in the first stretching bath with the fixing fluid in high temperature. As the tanks are made of stainless steel, the are anti-corrosive, and the plumbing made of brass, it is highly heat conductive. - SS-3800 Crimper

- This machine crimper the stretched yarns to make them look bulky. Two roller crimper the yarn under the same pressure and revolution to produce crimper in variety with little failure. A universal joint between the roller and the gear box helps minimize shearing press. And a air-cylinder in the stamping box regulates to control crimping.

Specification

|

1. 1ST-STRETCHER |

1SET |

|

SIZE |

2500x1210x(1550) |

|

FRAME |

100x50 STEEL CHANNEL |

|

ROLLER |

Ø 350x700, 7SET, HARD Cr PLATING |

|

MOTOR |

6P, 20HP(15Kw) |

|

REDUCTION GEAR BOX |

1SET |

|

BEARING |

#6318, 6216 |

|

CAPACITY |

1660KGS / HOUR |

|

2. 1ST-STRECHING BATH |

1SET |

|

SIZE |

2520×720×(850) |

|

FRAME |

75x40 STEEL CHANNEL |

|

BATH |

1500x460x300(SUS304) |

|

ROLLER |

Ø 350×650,2SET. HARD Cr PLATING |

|

BEARING |

#UCP312 4SET |

|

CAPACITY |

1200KGS / HOUR |

|

3. 2ND-STRETCHER |

1SET |

|

SIZE |

2500x1210x(1720) |

|

FRAME |

100x50 STEEL CHANNEL |

|

ROLLER |

Ø 350x700, 7SET, HARD Cr PLATING |

|

MOTOR |

6P, 30HP(22.5Kw) |

|

REDUCTION GEAR BOX |

1SET |

|

BEARING |

#6219, 6224 |

|

CAPACITY |

1660KGS / HOUR |

|

4. 2ND-STRECHING BATH |

1SET |

|

SIZE |

2520×720×(900) |

|

FRAME |

75x40 STEEL CHANNEL |

|

BATH |

2440x460x300, 1.2T SUS304 PLATE |

|

ROLLER |

Ø 350×650,2SET. HARD Cr PLATING |

|

BEARING |

#UCP312 4SET |

|

CAPACITY |

1200KGS / HOUR |

|

5. STEAM BOILER |

1SET |

|

MAXIMUM PRESSURE |

7Kg/Cm2 |

|

THERMAL EFFICIENCY |

90% |

|

FUEL |

Diesel Oil |

|

BURNER MOTOR |

0.4KW |

|

FEED WATER PUMP |

0.4KW,220/380V |

|

CONTROL PANEL |

1SET |

|

6. 3RD-STRETCHER |

1SET |

|

SIZE |

2500x1210x(1720) |

|

FRAME |

100x50 STEEL CHANNEL |

|

ROLLER |

Ø 350x700, 7SET, HARD Cr PLATING |

|

MOTOR |

300t / 20HP 6P(15KW) |

|

REDUCTION GEAR BOX |

1SET |

|

BEARING |

#6219, 6224 |

|

CAPACITY |

1660KGS / HOUR |

|

7. CRIMPER(one squeeze roller type) |

1SET |

|

SIZE |

1800×1750×(2287) |

|

FRAME |

100×50 STEEL CHANNEL |

|

STEAM BOX |

SUS304,1SET |

|

CRIMPER ROLLER |

300t /Ø200×200,2PCS |

|

SQUEEZE ROLLER |

Ø200x350,2PCS |

|

BEARING |

#5315,22315. |

|

REDUCTION GEAR BOX |

1SET |

| MOTOR FOR CRIMPER |

6P,30HP(18,75KW),1SET |

| MOTOR FOR SQUEEZE ROLLER |

6P,15HP(11,25KW),1SET |

| UNIVERSAL JOINT | 4SET |

| AIR CYLINDER | Ø 200x50ST, Ø65x100ST |

| CONTROL PANEL | 1SET (THIS CONTROL PANEL IS USED ALL STRECHING LINE) |

| CAPACITY |

1660KGS/HOUR |

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |