TPE Backsheet (TPE-35B)

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- Category

- Other Solar Energy Products

SFC Co., Ltd.

- Verified Certificate

-

17

| Product name | TPE Backsheet (TPE-35B) | Certification | - |

|---|---|---|---|

| Category | Other Solar Energy Products | Ingredients | - |

| Keyword | - | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | - |

Product Information

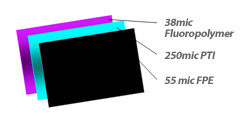

PV Backsheet TPE-35B

Back Film of SFC is manufactured to give a variety of designs from Thermoplastic and Fluor polymer, as a backing sheet for photovoltaic Solar Module due to its excellent strength, weather resistance, UV resistance and moisture barrier properties.

TPE-35B, The "TPT" is a multi-layered back film based on two layers of excellent durability fluoropolymer PVF film and one layer of high voltage insulation polyester film. Excellent durability fluoropolymer PVF films also provides good adhesion to EVA. The structure of "TPE-35B" has been designed to provide the best performance of properties in terms of superior UV resistance, moisture barrier, electrical insulation and weatherability.

TPE-35B Composition

|

Total Thickness

|

μm

|

358

|

|

|

Fluoropolymer

|

μm

|

38

|

|

|

Adhesive

|

μm

|

10

|

|

|

PTI

|

μm

|

250

|

|

|

Adhesive

|

μm

|

5

|

|

|

Fluoropolymer

|

μm

|

55

|

|

|

Total Weight

|

g/m2

|

430

|

Product Information (Properties)

|

Tensile Strength

|

MD

TD |

N/10mm

N/10mm |

>300

>300 |

ASTM D882

|

|

Elongation

|

MD

TD |

%

% |

>120

>100 |

ASTM D 882

|

|

Tear Strength

|

MD

TD |

N/mm

N/mm |

>350

>400 |

DIN 53363:2003

|

|

Dimensional Stability

|

MD 30min @ 150°C

TD 30min @ 150°C |

%

% |

<1.2

<1.0 |

ASTM D 1204

|

|

Peel Strength of EVA

|

0.2 m/min T-peeling

|

N/cm

|

>50

|

ASTM D1876

|

|

Water Vapor Permeability

|

38°C / 100% RH

38°C / 90% RH |

g/m2 . 24hr

g/m2 . 24hr |

<1.5

<3.3 |

ASTM F 1249

|

|

Breakdown Voltage

|

10mA

|

kV

|

>17

|

ASTM D 149

|

|

Maximum Permissible System Voltage

|

VDC

|

>1,000

|

IEC 60664-1

|

Remark

- Width : 800mm ~ 2000mm

- Color : white (Other colors on request)

- Cut sheets according to customer's request

Advantage of SFC PV Back Film

- Dimensional stability of backsheet makes vacuum lamination easier

- Less shrinkage both in machine and transverse direction of backsheet avoids wrinkles during processing

- Depending on type of EVA the initial adhesion values can vary greatly

Remark

* Width : 800㎜ ~2000㎜

* Color : white & Black (Other colors on request)

* Cut sheets according to customer's request

Advantage of SFC PV Back Film

* Dimensional stability of backsheet makes vacuum lamination easier

* Less shrinkage both in machine and transverse direction of backsheet avoids wrinkles during processing

* Depending on type of EVA the initial adhesion values can vary greatly

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Park Won-ki

- Address

- 456-3, Gong-ri, Guhang-myun, Hongseong-gun, Chungcheongnam-do,350-841, Korea

- Product Category

- Other Printing Materials,Solar Cells, Solar Panel,Stationery & Printing

- No. of Total Employees

- 51-100

- Company introduction

-

Since established in 1988, we have been making efforts to provide high quality and low-cost products to meet rapidly changing market requirements. We continuously invest in special Tracing Films, Off-set Printing Film, Color Inkjet OHP Film, Color Inkjet Paper and Photo Glossy Paper. All these are produced using our own facilities and our 14 years of technical know-how.

Around 90% of our output is now exported worldwide. In order to meet the increased market demands internationally and domestically, we finally started two big projects.

First is our new factory in Indonesia. It was established in December 2001 and was completely at the end of 2002. This is our second base for the European market, which will bring both SFC and our business partners considerable benefits and competitiveness. Secondly, we now have an up-to-date technical Extruding Tandem Machine. This allows us to meet the great demand at the highest level of quality.

- Main Markets

-

Australia

Australia

China

China

Indonesia

Indonesia

Poland

Poland

U.S.A

U.S.A

- Main Product

South Korea

South Korea

_2.png)