BEOT®-sintered metal filter

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Brand name

- BEOT

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- filter element, filter media, sinter metal filter, sparger

- Category

- Air Filter

BEOT Sinter Metal Filters Co., Ltd.

- Verified Certificate

-

15

| Product name | BEOT®-sintered metal filter | Certification | - |

|---|---|---|---|

| Category | Air Filter | Ingredients | - |

| Keyword | filter element , filter media , sinter metal filter , sparger | Unit Size | - |

| Brand name | BEOT | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | - |

Product Information

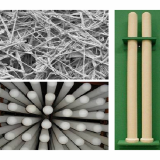

BEOT manufactures a wide range of standard materials for filtration and fluidization as well as filter elements with different size, and filtration ratings from 0.1 to 200 micron in form of Cylinder/Cartridge, Plate, Disc and Aerator/Sparger.

The seamless filter elements are manufactured by isostatic pressing or co-axial pressing via powder metallurgy process. Fittings and connector can be bonded to the porous parts by welding (TIG welding), machining or directly during sintering process.

Available materials are: stainless steel 316/316L, 304/304L, 310, 904, Titanium, Inconel, Hastalloy, Nickel, Monel and other alloys .etc. on request.

The pore size can be adjusted by suitable selection of the powder size fraction and the process parameters.

Production Capacity: 5000~6000 pcs per month

Main Application

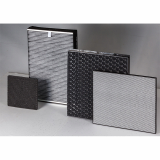

1. Gas and liquid filtration

2.Solid catalyst recovery

3.Filtration of slurry oil and other petrochemical products

4.High-temperature gas filtration

5.Fluidization

6.Powder conveying

7. Sparging and other applications in various industrial fields.

Main advantages

1. Good shape stability

2. High mechanical strengthen and good integrity

3. Controllable pore sizes and porosity

4. Good permeability

5. Good corrosion and thermal resistance

6. Easy to be made into complicated shapes, can be put together by soldering or gluing

7. The service life can be prolonged by cleaning and regenerating process

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Zhifeng Zhang

- Address

- No.336-2 Heping East Road

- Product Category

- Air Filter,Mining Machinery,Water Treatment

- No. of Total Employees

- 51-100

- Company introduction

-

BEOT Sinter Metal Filters Co., Ltd. is a leading company specialized in the development and production of sintered metal filters as well as design and installation of the complete sets of fluid equipment in China. BEOT offers a wide range of standard materials for filtration and fluidization as well as filter elements with a variety of end-fitting configurations, and filtration ratings from 0.1 to 200 microns.

More than 20 years of experience in the sintered porous metals industry makes BEOT uniquely qualified in the production of application-specific sintered metals and got the authentication of ISO9001 International Quality System and ISO4001 International Environmental Authentication.

Materials are available in alloys ranging from 300 Series stainless steels (ss316L, 304L) to Monel 400, Hastelloy C-22, phosphor bronze and other metals and alloys.

Goods are sold as far as to USA, Western Europe and Southeast Asia etc. and are well received by the customers. With its high strength, rigid structure, stable aperture, good permeability, high thermal and corrosion resistance, our sintered metal filters have been widely used in various industrial fields including Petrochemicals, Chemicals, Pharmaceuticals, Electronics, Environment, Brewing, Foodstuff and Beverage, especially used in catalyst recovery and hot gas filtration.

- Main Markets

-

China

China

Germany

Germany

India

India

South Korea

South Korea

U.S.A

U.S.A

- Main Product

Related Products

EDM Consumables

CERAMIC FILTER

Air Sterilizer with multi-layer filter system

Dust Collecting Filter

PTFE MEMBRANE FILTER BAG