High-viscosity Vertical Internal Cooling Bead Mill for grinding high-viscosity materials

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Other Machinery & Industry Equipment

Suzhou Tianli Mechanical & Electrical Equipment Co., Ltd

- Country / Year Established

-

China

/

China

/

- Business type

- Others

- Verified Certificate

-

13

| Product name | High-viscosity Vertical Internal Cooling Bead Mill for grinding high-viscosity materials | Certification | - |

|---|---|---|---|

| Category | Other Machinery & Industry Equipment | Ingredients | - |

| Keyword | bead mill , grinding machine , vertical ball mill , vertical bead mill | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | - |

Product Information

Application and Description

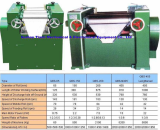

The machine is mainly used for grinding high-viscosity materials, such as offset printing ink, newspaper ink, industrial slurry, etc. It is ideal grinding equipment for effectively reducing the particle size. During the production process of offset printing ink, the equipment is usually used in conjunction with three roller mill.

Equipment characteristics

1) Automatically control the pressure of the grinding chamber to achieve the best grinding results.

2)Mechanical seal and bearing was connected in an open connection to avoid the impact of the spindle coupling in a state of high viscosity. Therefore the machine operation is more reliable and safe.

3)The double helix inner cooling water way can effectively release the heat generated by machine operation in high viscosity condition.

4)Mechanical seals from BURGMANN company, bearings from NSK company, dynamic separator made of powder alloy.

5)The machine can achieve the desired fineness of the materials for one time grinding only. It can be supported by three roller mill to complete the production process in a lump. The efficiency is highly increased.

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

Suzhou Tianli Mechanical & Electrical Equipment Co., Ltd

- Country / Year Established

-

China

/

China

/

- Business type

- Others

-

13

- President

- Eve Lin

- Address

- No.3, Jinxiu Road, Jiangsu Yangzijiang International Metallurgical Industrial Park, Jinfeng Town, Suzhou, Jiangsu, China (Mainland)- 215625

- Product Category

- Machinery & Parts

- Company introduction

-

We are a team of professionals using our collective expertise in the industry of chemical machinery manufacturing and marketing. Since founding, the company has been focusing on production, researching, developing, and service for Dispersing machines, Mixer, Grinder, Automatic Equipment for Painting, Emulsifiers, Vessels, Tanks, etc. We also provide customized machines for coatings applied in different area, Thermoplastic road painting, water based road painting, Inks, Putty, Mortar, Resins, Pigments, Additives, Adhesives, Cosmetics, Pharmaceuticals, Pesticides, Detergents, Washing powder, Modified emulsified asphalt, Paper and Paper chemicals, Rubber additives, Pharmaceutical intermediates, Bio-chemicals, Lubricants, Battery paste, Water treatment, Dyeing, Textile and Food, etc.

Our Focus is to be the preferred partner of chemical equipments, systems and services to industry leaders. We have over 10 years of experience working with these progressive companies. To better meet their on-going needs, we have changed from being simply an equipment supplier, into an integrated solutions provider. We have successfully supplied our clients from over 60 countries with the single machines, complete sets of equipment and production lines, as well as turnkey services of complete plants.

We work in partnership with our customers to provide the most cost-effective solution for their problem. Using our expertise, we work closely with your operating personnel to help them clearly define their requirements. Focusing on the best Solution requires us to have the flexibility to adapt to changing situations. Determining the best long-term Solution for our customer is a guiding principle on how we do business. We continually expand our ability to provide services in areas such as in-house service, on-site service / supplemental manpower, personnel training sessions and consulting on "best practices".

As a successful growing company, we are always looking to expand our portfolio to better meet our customers' needs.

- Main Markets

-

Brazil

Brazil

Kuwait

Kuwait

South Korea

South Korea

- Main Product

Related Products

Spare Parts for Hydraulic Breaker

New High Pressure Exhaust Fan(30cm)

AIS3000 HD

Small Sirocco Fan(TIS-190FS, TIS-190FT)

Portable line boring machine, Elsa Supercombinata EASY Compact