Three Layer Shrink Sleeve with Epoxy Primer HS-3401

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- Category

- Tapes & Glues

Shaic International Co.

- Verified Certificate

-

17

| Product name | Three Layer Shrink Sleeve with Epoxy Primer HS-3401 | Certification | - |

|---|---|---|---|

| Category | Tapes & Glues | Ingredients | - |

| Keyword | - | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | - |

Product Information

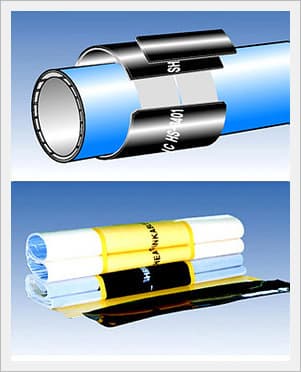

SHAIC HS-3401 three-layer heat shrinkable wraparound sleeve is designed for welded joint protection with epoxy primer of plastic coated steel pipelines. It has a thick crosslinked polyethylene backing coated with heat sensitive adhesive and two part of liquid epoxy primer. Apply epoxy primer to the pipe surface and then adhesive flows and forms a reliable corrosion protection seal onto epoxy and adjacent coating surfaces.

Long-Term Corrosion Protection

After heating, formed corrosion protection seal and strong backing provides outstanding waterproofing effect and high chemical resistance. SHAIC HS-3401 3-layer corrosion protection system resists impact, abrasion and ultraviolet light as well as excellent resistance against cathodic disbondment, dielectric breakdown.

Bulk Rolls

SHAIC HS-3401 is supplied in bulk rolls, which is cut in the field for any size of pipe. No need to drive to warehouse and just cut customized length in the field in time that reduces inventories and saves the cost & time.

Sub-Materials

- Epoxy primer Base & Cure

- Applicator pad

- Mixing cup

- Stirring stick

- Roller

- Digital Thermometer

- Pump

- Torch

Flexible Installation

SHAIC Heat Shrinkable sleeve can be used 3-layer or 2-layer installation upon your specific project requirement. Please contact with our representative for appropriate installation. Apply epoxy primer over foreign matter-free and preheated surface. Wrap the sleeve around the pipes. Fix the center of preheated patch closure on the overlapped end and start to heat sleeve in the center. Move the torch around pipe circumferentially to heat the left and the right of sleeve. Finish off by heating vertically over the entire sleeve to ensure a uniform adhesion and by using a roller or gloved hands to remove wrinkle and air.

Accompanying Equipment

|

|

|

|

|

hand roller for straight

|

applicator pad

|

digital thermometer

|

mixing cup

stirring stick |

Physical Properties

|

Properties

|

Test Method

|

Values

|

|||

|

Inner Layer

|

Softening Point

|

ASTM E28

|

75°C(167°F), 85°C(185°F), 95°C(203°F)

|

||

|

Lap Shear 23°C

|

DIN 30672

|

420psi

|

|||

|

Outer Layer

|

Tensile Strength

|

ASTM D638

|

17Mpa↑ (2500psi)

|

||

|

Elongation

|

ASTM D638

|

400% ↑

|

|||

|

Hardness

|

ASTM D2240

|

45

|

|||

|

Heat

Aging |

Elongation

|

After 70days

|

ASTM D638(DIN 30672)

|

528°C

|

|

|

After 100days

|

524°C

|

||||

|

Tensile

Strength |

After 70days

|

196N/10mm2

|

|||

|

After 70days

|

191N/10mm2

|

||||

|

Volume Resistivity

|

ASTM D257

|

1015↑

|

|||

|

Dielectric Breakdown

|

ASTM D149

|

32kV

|

|||

|

Sleeve

|

Impact Resistance

|

ASTM G14

|

pass holiday detection test with

|

||

|

Penetration Resistance

|

ASTM G17

|

15kV detector

|

|||

|

Peel Strength at 23°C

|

DIN 30672

|

68N/cm

|

|||

|

Water Absorption

|

ASTM D570

|

0.1%↓

|

|||

|

Cathodic Disbondment

|

at 23°C

|

ASTM G8

|

7.5mm

|

||

|

at 80°C

|

ASTM G42

|

15mm

|

|||

|

Adhesion Strength

|

To. P/E

|

ASTM D 1000

|

40N/cm

|

||

|

To. Steel

|

68N/cm

|

||||

|

Operating Temperature

|

-10°C to 90°C

|

||||

Ordering Information

|

Standard Cut Sleeve

|

||

|

Super Heav Duty Thick.(S)

|

Heavy Duty Thick.(H)

|

Regular Thick.(R1)

|

|

|

BL-Black, YE-Yellow

|

|||

|

12", 18", 24"(300, 450, 600mm)

|

|||

|

2"~100"(DN50-2500)

|

2"~100"(DN50-2500)

|

2"~80"(DN50-2000)

|

|

|

1.8mm

|

1.6mm

|

1.25mm

|

|

|

S-1.2mm

|

H-1.0mm

|

R1-0.75mm

|

|

|

C-Cut Sleeve with Patch Closure

|

|||

|

Bulk Roll

|

||

|

Super Heav Duty Thick.(S)

|

Heavy Duty Thick.(H)

|

Regular Thick.(R1)

|

|

|

BL-Black, YE-Yellow

|

|||

|

12", 18", 24"(300, 450, 600mm)

|

|||

|

100ft(30m)

|

|||

|

1.8mm

|

1.6mm

|

1.25mm

|

|

|

S-1.2mm

|

H-1.0mm

|

R1-0.75mm

|

|

|

R-Bulk Roll

|

|||

|

Bulk Roll Patch Closure

|

||

|

Regular Thickness(R)

|

|||

|

BL_Black, YE-Yellow

|

|||

|

12"(300mm), 18"(450mm)

|

|||

|

50ft(15m)

|

|||

|

1.2mm

|

|||

|

RP-Bulk Roll Patch Closure

|

|||

| *Note 1. Min. Sleeve Width=Base Steel Width + 2"(50mm) min. on each side of the pipe joint 2. Various width, length and thickness are available for project requirements. |

|||

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- HAN YOUNG MI

- Address

- 316-6 Bonsan-ri, Jinyoung-eup,, Gimhae-si, Gyeongsangnam-do

- Product Category

- Adhesive Tapes & Papers,Packing Sealing Adhesive Tapes

- Company introduction

-

Sam Hwan Anti-corrosion Industrial Co.(SHAIC) is the leading company manufacturing the anti-corrosion materials for gas, oil & water pipelines and established in 1995.

We specialize in producing & exporting heat shrinkable sleeve for welded joint of oil, gas pipes and coating tapes for water pipeline. To meet customer's needs, we always develop the various corrosion protection materials in onshore & offshore.Our worldwide sales network system provides customers with good quality services & information in technical support & corrosion protection industry.

With the continuous research & investment, we make effort to advance in technology and develop new products.

Supplying the various products with competitive price, we are expending our business area abroad. We promise to be the most trusted company in corrosion protection industry.

- Main Markets

-

Iran

Iran

Israel

Israel

Italy

Italy

Thailand

Thailand

Turkey

Turkey

- Main Product

Related Products

EYELASH GLUE

Eyelash extension glue

Glue for pest control

HOT MELT ADHESIVE for LABELING

PVC Floor Line Marking Tape

South Korea

South Korea