Steam Turbine

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- Category

- Other Generators

Doosan Heavy Industries & Construction Co., Ltd.

- Country / Year Established

-

South Korea

/

1962

South Korea

/

1962

- Business type

- Manufacturer

- Verified Certificate

-

17

| Product name | Steam Turbine | Certification | - |

|---|---|---|---|

| Category | Other Generators | Ingredients | - |

| Keyword | - | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | - |

Product Information

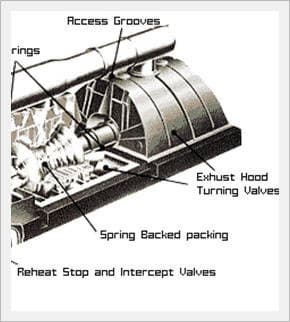

Features

- Front Standard can slide horizontally, so it maintains a clearance in the axial direction and even sealing in heat expansion. It includes Thrust and Journal bearings.

- Thrust Bearing incorporates a taper design. Thrust collars are modular with rotor.

- Journal Bearing is consisted of Tilting Pad or Elliptical Type with vibration and bearing metal temperature sensors.

- Single-casing HP/IP section forms a stage based on Impulse Design that can withstand more than 50% energy when compared to an Impulse Design. The turbines with HP and IP sections inside a single casing is 7 meters shorter than the turbines with a separate casing for HP and IP sections. So the Single-Casing HP-IP turbines can reduce the installation cost by 15~20% when compared to the Separated Casing HP/IP turbines, while having other features like 10% reduced maintenance cost and minimized heat stress at starting and loading.

- Turbine rotor is manufactured by forging a solid mono-block. Its integral wheel integrated with bucket dovetail, small rotor radius at high temperature area, and the wheel fillet speed up the starting and loading time by reducing the heat stress.

- Nozzle Box (at first stage) enables the partial-arc admission, while its multiple-shell structure is designed to ensure maximum heat efficiency.

- Nozzle Diaphragm is welded along the axial line, so that the gap between the stages is maintained accurately.

- Bucket is installed so that the dovetail on rotor is fixed in place. With highly effective form and corrosion coating, it's designed to efficiently accomplish the function during the lifespan.

- The casing, bucket and flow diffuser of Low Pressure Section are designed to have the optimal efficiency with three dimensional steam flow analysis and fluid dynamics.

- Last stage bucket is designed to have high corrosion resistance without the need for a separate resistance shield, by using three-dimensional dynamic analysis and reinforced materials.

- Labyrinth packing greatly improves the efficiency by sealing the gap between stages and axial ends.

- Single Crossover is designed to have very low-pressure drops. It's pressure-balanced expansion join is suitable for heat expansion and designed to minimize the stress on casing.

- Valves and hydraulic actuators: The independently powered control and stop valves enable for full or partial-arc operation. Also the design of reheat stop consisted of combined reheat valve with strainer, single casing and vertical stem allows for easy maintenance. The actuator controls the location of valves by using internal fluid.

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Geewon Park

- Address

- 555, Gwigok-dong,, Changwon-si,Gyeongsangnam-do,

- Product Category

- Other Machinery & Industry Equipment

- Year Established

- 1962

- Company introduction

-

Doosan is building a brighter and happier future for people with its power plant technology implemented in Sipat, India, Tennessee, USA, Shuaibah, Saudi Arabia, Ras Laffan, Qatar, and Qinshan, China. Doosan has so far built over 300 nuclear, thermal, combined cycle and hydro power plants. Doosan is currently building more than 60 power plants in Korea, USA, India, China and other countries. Doosan is fast becoming an EPC contractor as a result of continuous investments and R&D, while also developing wind power systems, fuel cells and environmentally friendly next-generation energy. Doosan is currently the best in the field of MSF (Multi Stage Flash) desalination with a global market share of over 40%. Doosan is the one that built the world`s largest Shuaibah Desalination Plant Phase 3 with a daily desalination capacity of 880,000 tons in Saudi Arabia as well as the world`s first hybrid desalination plant combined with both MSF and RO systems in Fujairah, UAE. Doosan is one of the few companies in the world that has proprietary technologies for all the three desalination methods, which are MSF (Multi Stage Flash), MED (Multi Effect Distillation) and RO (Reverse Osmosis). Doosan also supplies casting and forging products, which are the basic materials for power and desalination plants. Doosan is one of the best companies in the world in SOC projects such as road, port, airport and subway construction as well as in the construction of industrial plants. Doosan will strive to become the 'No. 1 Global Company' through continuous corporate restructuring, marketing expansion, technology R&D and development of new growth engines.

- Main Markets

-

China

China

India

India

Qatar

Qatar

Saudi Arabia

Saudi Arabia

U.S.A

U.S.A

- Main Product

Related Products

MAN B W 6L23/30H genset

DC Motor

OZBP-20A( BLDC Position Control Driver)

Honda EU3000i Handi Generator

Honda EB10000 - 9000 Watt Portable Generator