Polyethylene Panel Manufacturing Line

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- Category

- Other Metal & Metallurgy Machinery

Samshin Machinery Co., Ltd.

- Country / Year Established

-

South Korea

/

South Korea

/

- Business type

- Others

- Verified Certificate

-

17

| Product name | Polyethylene Panel Manufacturing Line | Certification | - |

|---|---|---|---|

| Category | Other Metal & Metallurgy Machinery | Ingredients | - |

| Keyword | - | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | - |

Product Information

Description

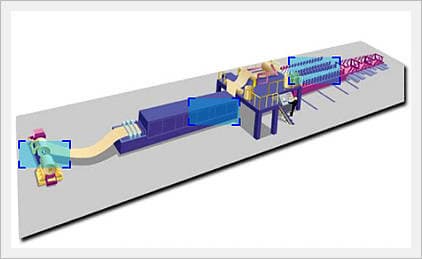

This line is designed to make a double layered panel - steel sheet and polyethylene sheet, which is widely used for a wall and roof.

The line consists of uncoilers, which are one for steel sheet and one for polyethylene sheet, heating machine to attach polyethylene sheet on the steel sheet, forming machine, cutting machine and run out conveyor.

Feature of Polyethylene Panel Line

- As steel sheets can be sticked by thermal fusion and adhesives, you can choose various types of insulating materials.

- You can freely adjust where insulating materials should be adhered

- With even automatic temperature control of infrared heating system, there is no excessive adhesive and color change on the surface

- Formed by a double cooling device in it, the paint of steel sheet cannot be peeled off

- Prompt Post Management with the standardization of all parts

Features of Polyethylene Panels

- Incombustibility(UP-KIM)

With self-fire extinguishing property, this is used as an incombustible or a semi-incombustible material. - Insulation

It shows excellent insulation of 0.020 to 0.031 kcal/mh°C - Dew-proof

Due to high insulation, there is no dew and water-drop - Temperature resistance

Under hot temperature, it shows high insulation effect - Sound-proof

it absorbs vibration and noise from rain-drop - Chemical resistance

- Applicability

Since it is light, flexible and easy to cut, it can be shaped by normal forming machine.

Specification

|

Item

|

Specification

|

|

|

Line Speed

|

Max. 9 M/min

|

|

|

Product

|

Width

|

Max. 1,219 mm

|

|

Thickness

|

4 ~ 10 mm

|

|

|

Length

|

Min 1,500 mm ~ Max. 15,000 mm

|

|

|

Coil

|

Material

|

Pre-painted steel sheet

|

|

Width

|

914 ~ 1,219 mm

|

|

|

Thickness

|

0.45 ~ 0.8 mm

|

|

|

Weight

|

Max. 5,000 kg

|

|

|

Insulation

|

Material

|

Polyethylene Sheet

|

|

Width

|

Max. 1,100 mm

|

|

|

Thickness

|

2 ~ 10 mm

|

|

|

Density

|

40 ~ 50kg/m3

|

|

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- LEE, DAE-SIK

- Address

- 1007-2, Hwabong-ri, Eunha-myeon, Hongsung-gun, Choongcheongnam-do, KOREA

- Product Category

- Other Metal & Metallurgy Machinery

- No. of Total Employees

- 1-50

- Company introduction

-

Since our foundation, we have made roll forming machines, insulated sandwich panel lines mainly for construction material production.

There are different production machines within roll forming machines, such as for producing deck plate(flooring), ceiling, wall, roof, gutters, end covers, extra construction materials and auto mobile parts. Applying this roll forming machine, we are also specialized in insulated sandwich panel lines using EPS boards, mineral wool boards and polyurethane.

Till 2004, we were focusing on domestic markets only and we have good reputation on qualified machines and prompt and appropriate services. And from 2005, we are expanding our markets into the world and step by step, we are satisfying our global customers with our qualified goods and services.

We have made steady efforts to improve the quality of the products made by our machinery and do our best for the development of new technology for easier operation and better productivity. It is our commitment to make a dedicated company providing the highest technology and service in a forming machine field. To achieve this qualification, we got international quality and environmental system of ISO9001 and 14001.

In 2007, we won Korea World Class Product Award by Korean Government, proving our high technology.

In 2008, our effort on quality and easy operation of machine brought us to have CE quality standard in our system.

In 2010, we won the Seal of Excellence by KOTRA.

- Main Markets

-

Colombia

Colombia

Japan

Japan

Kazakhstan

Kazakhstan

Russia

Russia

Uzbekistan

Uzbekistan

- Main Product

Related Products

10t Air drop hammer, mod. M2150, Kramatorsk

Date Pin (Date Core)

Automatic precision metal cutting machine

_2.jpg)

Electric Furnace (Conveyor Type Furnace)

UIM2901-5A MACH3 break out board for CNC