GEN Series Insulating Fire Brick/ Lightweight

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Brand name

- GEN IFB

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- insulation, refractory, ifb, insulating fire brick

- Category

- Refractory

GENCO CO.,LTD

- Country / Year Established

-

South Korea

/

South Korea

/

- Business type

- Others

- Verified Certificate

-

14

| Product name | GEN Series Insulating Fire Brick/ Lightweight | Certification | - |

|---|---|---|---|

| Category | Refractory | Ingredients | - |

| Keyword | insulation , refractory , ifb , insulating fire brick | Unit Size | - |

| Brand name | GEN IFB | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | 690310 |

Product Information

Description

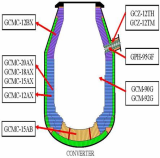

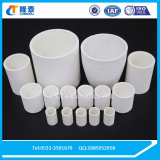

GEN Insulating Fire Bricks are specially characterized by their excellent porous structure, thermal conductivity, heat expansion, mechanical strength, low weight and high thermal insulating properties suitable for minimizing a heat loss and maximizing a heat conservation in industrial kilns and furnaces behind a refractory lining. GEN Insulating Fire Bricks are manufactured by using sawdust & Styrofoam and designed for a maximum service temp. 1100°C to 1760°C.

Features

* Various Max. Service Temp.: 1100°C to 1760°C

* Excellent insulating properties

* High Mechanical Strength

* Light Weight

* Good insulation Value

* Good Thermal Shock Resistance

|

Grade |

GEN-20S |

GEN-20 |

GEN-23S |

GEN-23 |

GEN-26 |

GEN-28 |

GEN-30 |

GEN MULTI -32 |

|

|

Maximum service temperature |

|||||||||

|

|

°C |

1100 |

1100 |

1260 |

1260 |

1430 |

1540 |

1650 |

1760 |

|

|

°F |

2012 |

2012 |

2300 |

2300 |

2600 |

2800 |

3000 |

3200 |

|

Bulk density, dried at 110°C |

|||||||||

|

|

kg/m3 |

500≥ |

500±50 |

500≥ |

500±50 |

700±50 |

900±50 |

1000±50 |

1250±50 |

|

Cold crushing strength |

|||||||||

|

|

MPa |

1.2 |

1.2 |

0.9 |

1.2 |

1.7 |

2.2 |

2.6 |

3.5 |

|

|

lbs/sq.in. |

174 |

174 |

131 |

174 |

247 |

319 |

377 |

508 |

|

Llinear thermal expansion (ASTM C-210) |

|||||||||

|

|

% |

0.5≥ |

0.5≥ |

0.5≥ |

0.5≥ |

0.5≥ |

0.7≥ |

1≥ |

1≥ |

|

|

°C |

1070 |

1070 |

1230 |

1230 |

1400 |

1510 |

1620 |

1700 |

|

Thermal conductivity (ASTM C-182) |

|||||||||

|

mean temp. @200°C |

W/(mK) |

0.11 |

0.13 |

0.15 |

0.12 |

0.25 |

0.30 |

0.36 |

0.46 |

|

@400°C |

0.13 |

0.15 |

0.17 |

0.14 |

0.27 |

0.32 |

0.38 |

0.48 |

|

|

@600°C |

0.15 |

0.17 |

0.18 |

0.16 |

0.29 |

0.34 |

0.41 |

0.50 |

|

|

@800°C |

0.15 |

0.19 |

0.21 |

0.16 |

0.31 |

0.36 |

0.42 |

0.51 |

|

|

@1000°C |

0.19 |

0.23 |

0.25 |

0.20 |

0.33 |

0.38 |

0.44 |

0.53 |

|

|

@1200°C |

- |

- |

0.27 |

0.23 |

0.35 |

0.41 |

0.47 |

0.56 |

|

|

|

|||||||||

|

@392°F |

BTU/ (sq.ft.×h×°F/in) |

0.76 |

0.90 |

1.04 |

0.83 |

1.73 |

2.08 |

2.50 |

3.19 |

|

@752°F |

0.90 |

1.04 |

1.18 |

0.97 |

1.87 |

2.22 |

2.64 |

3.33 |

|

|

@1112°F |

1.04 |

1.18 |

1.25 |

1.11 |

2.01 |

2.36 |

2.84 |

3.47 |

|

|

@1472°F |

1.04 |

1.32 |

1.46 |

1.11 |

2.15 |

2.50 |

2.91 |

3.54 |

|

|

@1832°F |

1.32 |

1.59 |

1.73 |

1.39 |

2.29 |

2.64 |

3.05 |

3.68 |

|

|

@2192°F |

- |

- |

1.87 |

1.59 |

2.43 |

2.84 |

3.26 |

3.88 |

|

|

Chemical analysis, typical (%) |

|||||||||

|

Silica |

SiO2 |

53.21 |

39.80 |

43.00 |

43.20 |

46.90 |

27.90 |

27.30 |

21.30 |

|

Alumina |

Al2O3 |

41.35 |

42.10 |

51.80 |

52.00 |

48.30 |

70.50 |

71.10 |

77.10 |

|

Titanium dioxide |

TiO2 |

1.56 |

0.58 |

1.02 |

1.32 |

0.12 |

0.11 |

0.10 |

0.11 |

|

Ferric oxide |

Fe2O3 |

1.23 |

0.86 |

1.14 |

0.63 |

0.76 |

0.40 |

0.43 |

0.43 |

|

Calcium oxide |

CaO |

0.65 |

13.80 |

0.52 |

0.56 |

0.89 |

0.24 |

0.23 |

0.18 |

|

Magnesium oxide |

MgO |

0.12 |

0.63 |

0.13 |

0.15 |

0.16 |

0.10 |

0.10 |

0.20 |

|

Potassium oxide |

K2O |

0.99 |

0.81 |

0.94 |

0.92 |

1.22 |

0.26 |

0.25 |

0.23 |

|

Sodium oxide |

Na2O |

0.37 |

0.39 |

0.34 |

0.33 |

0.23 |

0.32 |

0.28 |

0.26 |

|

Loss on ignition 1025°C (1877°F) |

LOI |

0.15 |

0.07 |

0.12 |

0.12 |

0.04 |

0.01 |

0.02 |

0.01 |

|

Colour |

WHITE |

BEIGE |

WHITE |

WHITE |

WHITE |

WHITE |

WHITE |

WHITE |

|

- Product Info Attached File

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- BIOH CHO

- Address

- 1435-13,ONCHEON-DONG, DONGNAE-GU,BUSAN,KOREA

- Product Category

- Lubricant,Refractory,Vehicles & Accessories

- Company introduction

-

We are manufacturer for nano products(nano water, nano diamond etc.), Refractories and insulating fire products(ceramic blanket, calcium silicate board and insulating fire brick etc.)

And, we supply DIANANO for engine oil or lubricant for industries.

Pls. visit www.genco.co.kr or www.dianano.co.kr

- Main Product