Dynamic Gas Spring

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- Category

- Shock Absorbers

Hanil Precision Co., Ltd.

- Verified Certificate

-

16

| Product name | Dynamic Gas Spring | Certification | - |

|---|---|---|---|

| Category | Shock Absorbers | Ingredients | - |

| Keyword | - | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | - |

Product Information

Dynamic Damping Type

The gas spring is usually mounted on the tail gate or hood/bonnet, thus makes easy of lifting/lowering the coverlet. The gas spring is consisted with pressure tube(Cylinder), piston rod(Shaft), oil seal and other components.

Overview

The feature of dynamic gas spring

Unlike conventional hydraulic damping type by controlling piston orifice as oil passage, the dynamic gas spring give user very soft damping feeling and closing/open effort. It is available to set up the extension and compression speed of the piston rod for optimized usage condition by varying the groove parameter.

How to dynamic damping work

In this type of gas spring, piston does not have orifice in order for gas itself to run through the channel which is slotted on Speed the cylinder surface.

Demonstration of dynamic gas spring when it is mounted on the tail gate

Feature

- Various range of application:

From the furniture to automotive - Merit of gas spring

1. Sustaining of the constant elasticity change rate even in the high reaction force and long stroke.

2. Compact design and appearance.

3. Easy mounting and installing in any application at any position.

4. Automatic operational dampering function without any additional adjustment device.

5. Compression and extension speed adjustable.

6. Reaction force will be adjustable at any time of usage.(in case of charge up) - Various endfittings

Specification

Material Specification

- Tube(Cylinder) : STKM12

- Piston Rod : S-454C, 25C(with nitride treatment)

- Gas : Nitrogen 99.99% purity

Standards Test

- Tensile strength test : Min. 5,000N

- Life cycle test(Min. 40,000 times)

- High temperature test at +80°C

- Low temperature test at -30°C

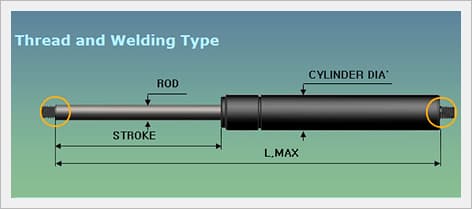

Model No.

|

MODEL. NO.

|

Rod DIA(mm)

|

CYLINDER DIAm(mm)

|

L.MAX(mm)

|

STROKE(mm)

|

FORCE(N)

|

|

HS0-Seal

|

6

|

15

|

100-500

|

30-150

|

10-400

|

|

HS1-Seal

|

8

|

18

|

100-700

|

50-200

|

50-800

|

|

HS2-Seal

|

10

|

22

|

150-900

|

70-255

|

50-1200

|

|

HS3-Seal

|

12.5

|

27.4

|

200-900

|

100-300

|

100-1500

|

|

HS4-Seal

|

12.5

|

22

|

200-900

|

100-300

|

100-1500

|

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- JeeHong Lee

- Address

- 98-17 Sangdong-ro Sangdong-myeon Gimhae Gyeongnam Korea

- Product Category

- Other Vehicle Accessories

- No. of Total Employees

- 101-500

- Company introduction

-

One of the leading gas spring manufacturer in the world, established in 1984, hanil precision Co.,Ltd has occupied top position in the domestic and international market as well.

Hanil had supplied to SHARP Corp. and CATER PILLER Corp. with obtaining quality approval in 1988. From 1984 to present, Hanil precision has various customer which are Proton, Mitsubishi and the other famous agricultural machine company and heavy equipment company let alone domestic motor company, Deawoo, Hyundai and Ssanyong. And always had a excellent reputation for quality and service from the all around the world. Hanil's stringent quality system and competative price has offically proven by ISO 9001/ QS9000 certification since 1999.

Established small quantity batch production system by accumalating of special production know-how, hanil precision is ready to serve you the best quality gas spring as the most qualified dampening system provider

- Main Markets

-

Czecho Republic

Czecho Republic

Italy

Italy

Sweden

Sweden

U. Kingdom

U. Kingdom

U.S.A

U.S.A

- Main Product

South Korea

South Korea