Korea Lintec Shaft

- Verified Certificate

-

14

| Product name | RodEnd and Comfollower,Track Roller | Certification | - |

|---|---|---|---|

| Category | Bearings | Ingredients | - |

| Keyword | - | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | - |

Product Information

Guide Features

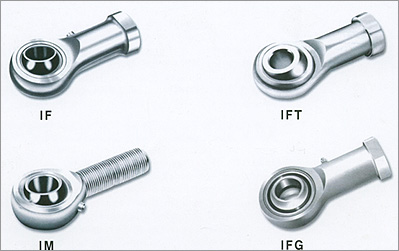

ROD ENDS

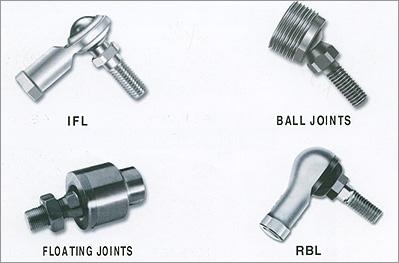

BALL JOINTS

TRACK ROLLERS

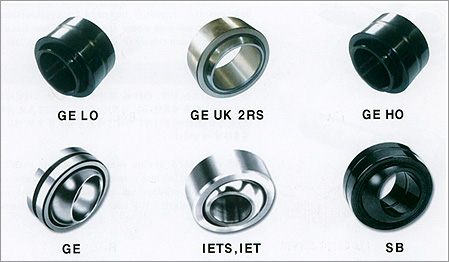

SPHERICAL PLAINS

ROD ENDS

|

Type IF & IM Type IFT & IMT Type IFTS & IMTS |

SPHERICAL PLAINS

|

Type GE |

|

Type SB These spherical plains are self-aligning and sliding bearings for heavy loads which are hardened, ground and then phosphated. It is made out of carbon chromium bearing steel, too. SB is wider and thicker than GE and is suitable for more heavy loads than GE. In general, periodic or continuous lubrication is required and lithium base grease with molybdenum is recommended. |

|

Type IS The outer ring is carbon steel but not hardened, so you should be cautious not to damage it when you assemble. There is minimum 20/1,000mm of clearance between the inner ring and the outer ring. Be sure that the inner ring rotate freely after make up. Improper assembling may cause bad operating conditions. The surface of the inner ring is polished and finished like a mirror and copper alloy is inserted in the sliding contact surface of the outer ring. The copper alloy has a good wear resistance. IS is also one of the sliding bearings with accommodating misalignment. |

|

Type IET The outer ring of this spherical plain is also made of carbon steel and is not hardened, so you have to pay attention when you fit it in order to avoid the damage of the outer ring. In accordance with international standard, we designs this type IET which can be used in a small area. A PTFE liner is overlaid on the contact surface of the outer ring. This enables the bearing to work without lubrication because of it's excellent sliding and wear resistance property. In many cases, they can operate without maintenance, nobeullije Non oil contained material. |

|

Type IETS It is made of stainless steel to prevent corrosion and a PTFE liner is overlaid on the contact surface of the outer ring. It is suitable for the chemical applications and under water equipment. |

BALL JOINTS

|

Type RBL RBL are kinds of bearings for linkage control, which are rotating and oscillating to make it easy for rod linkage motion in various industrial machinery. Stud bolts and high precise steel balls are welded together electrically. Rubber caps are used to keep waterproof and rustproof and to contain grease for self lubrication. The material of the RBL body is Zn-alloy and the body is molded by die-casting. In comparison with the conventional rod ends connected with pins, this RBL has a simple structure and a wide variety of industrial applications. |

|

Type FLOATING JOINTS These are such types stud bolts welded electrically with high precise steel balls are assembled to the steel body. They are used for linear motions to absorb the moment resulted from eccentricity and unparallelness when rigged at the end of hydraulic and pneumatic cylinders. They also guarantee an extended long life of hydraulic and pneumatic cylinders. |

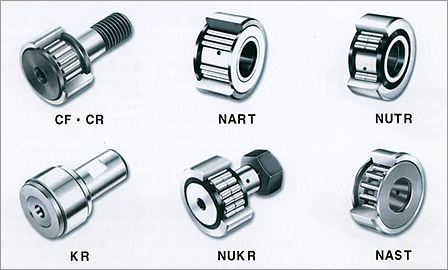

STUD TYPE TRACk ROLLERS

|

Type CF & CR |

|

Type CFE |

|

Type CFO CFO is one of our non-standard stud type track rollers. This type also has the same elements and working range that CF and CR have. However this makes a difference with respect to application. CFO has a thread for piping at the end of stud, so they can take the grease supply from the central lubrication system. The most of CFO type are applied to this purpose. |

|

Type NUKR IMC stud type track rollers of series NUKR start with an outside diameter of 35mm and end with an outside diameter of 90mm. They are equipped with two rows of needle rollers without cage. These are suitable for high loads. NUKR..R which feature crowned outer ring are available. NUKR..SL with cylindrical outer ring are required to make by a special order. |

YOKE TYPE TRACk ROLLERS

|

Type NART There are two kinds in a series of NART which is a non-separable type, one has a retainer (or cage) to make needles rotate freely at high speed and the other is just stuffed with needles so as to endure heavy loads at relatively low speed. The range of bore diameter is from 5mm to 50mm and NART..R which has crowned outer ring is our regular products. The interval of lubrication is subject to operating conditions and it is normally from six months to two years for caged one can every six months for full complement of needle roller. You may lubricate through a lubricating hole with Albania type grease which has good performance at high temperature. When you assemble NART to the housing you should position the lubricating hole on the other side of a load direction. |

|

Type NUTR Yoke type track rollers of series NUTR are one kind of NART in which only needles are stuffed without retainer. The bore diameter and outside diameter of this series start with 15mm and 35mm respectively. There are two types of NUTR which have the different outside diameter even though it has the same bore diameter, for example NUTR15-35, NUTR15-42. Moreover, NUTR..R has crowned outer ring, but NUTR..SL has cylindrical outer ring. NUTR series a dopt double row of needle roller to withstand high loads and well designed to withstand repeated impact loads. There are steel ring labyrinths which make it to be a non-separable type by connecting the outer ring and the retaining washers. The steel ring labyrinths also have the effect to be sealed to prevent contamination. Working temperature doesn't matter with the steel ring labyrinths because they are not in contact with working areas. When you assemble this, position the lubricating hole on the other side of a load direction in order to avoid load concentration. |

|

Type NAST Yoke type track rollers of series NAST are newly developed to satisfy our customer's increasing requirements. This type is one of our standards and consists of an inner and an outer ring, retaining washer and a precision cage. This NAST... characterizes not to have a thrust washers fixed with inner ring. NAST..ZZ which has two retaining washers on both sides is a little different from NART. The thrust washers of series NART are pressed into the inner ring, thus making the rollers unseparable. in series NAST, the retaining washers are loose and the rollers are separable. NAST are all separable types. |

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

Korea Lintec Shaft

-

14

- President

- Woo-ho Lee

- Address

- #1208-Ga Dong(ChungAng Circulation Complex,Guro-Dong)15,Gyeongin-Ro,53-Gil, Guro-gu, Seoul, Korea

- Product Category

- High Precision Bearings

- Year Established

- 2002

- No. of Total Employees

- 1-50

- Company introduction

-

Greetings to customers all around the world!

Our company have been producing all sorts of shafts and exporting to the international market. Our brand "KLS" Shaft (Korea Lintec & Shaft) has been acknowledged for great quality control, competitive pricing, and punctual and fast delivery. Exports have been increasing continuously due to our excellent reputation of great deals and quality by our customers.

Especially, we have developed HPJ Brand's LM Bushings overseas (China), of which trademark HPJ has registered in Japan, which is used with our Shaft and we are exporting them in parallel, and has established ourselves as a maker of LM System. Any Buyers who has imported our Shaft and LM Bushings takes advantage of our

1) Competitive price

2) Top quality products

3) Fast delivery

and continues to do buy our "KLS" Brand Shafts and HPJ Brand LM Bushings. The long term relationship we maintain with these buyers are our greatest strengths.

And,also we are producing many other concerned Items such,

1) "Support Unit",

2)"Micro Coupling"

3)"Lock Nut" for Ball Screw,

4)"TM(Lead) Screw,

5)"Cross Roller Guide","Sector Elignment Stage" is No.2 in the world makers/factories

6)"Miniature Liner Guide",

7)"RodEnd & Camfollower", "Track Roller",

8)"Thrust Roller Bearings",etc.,

are all for Factory Automation Systems,and also for Robot Systems.

Therefore, in 2015, we will put our best effort into increasing our exports, and we promise you that we will be the number one Brand of above all Products in the near future.

Chief Representative: Woo Ho Lee

- Main Markets

-

Germany

Germany

- Factory Information

-

KLS,

Korealintec & Shaft

- Main Product

Related Products

THK Linear Bearing

Sapphire ring/ Sapphire bearing/ Sapphire o ring/ Micro ring

Bones Bearing

KBC Bearing

KOREAN MADE EXCAVATOR SPARE PARTS(DOOSAN/HYUNDAI/VOLVO/ETC)

South Korea

South Korea