Double Sealing Resilient Seated Gate Valves for Water Works

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- Category

- Valves

- Country / Year Established

-

South Korea

/

South Korea

/

- Business type

- Others

- Verified Certificate

-

15

| Product name | Double Sealing Resilient Seated Gate Valves for Water Works | Certification | - |

|---|---|---|---|

| Category | Valves | Ingredients | - |

| Keyword | - | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | - |

Product Information

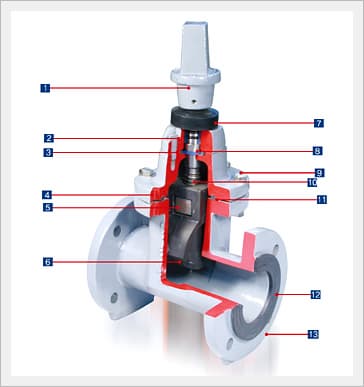

Double Sealing Resilient Seated Gate Valves for Water Works

Sluice Valve with both side soft seal preventing other foreign particles from outside

Double Sealing Resilient Seated Valves for Water Works has no difficulty for maintenance of facilities because flange dimension and switching speed of conventional gate valve K2332 are the same as those of Double Sealing Resilient Seated Valves for Water Works.

Characteristic of the products

- As the material of component is made of ductile iron (GCD450, GCD500), it can absorb internal/external shocks and stand wrecking

during winter season. And it is sanitary because of no rust and no water scale due to epoxy resin powder coating. - In particular, in case of our products (Utility Model Patent: No.0224565), as other foreign particles such as sand and dust can not be inserted into between part of valve stem & packing box covered with rubber cover, it is working well in spite of long time using.

- As rubber packings after grooving of both flanges were attached (Utility Model Patent: No.0224565), there is no leakage during high pressure and it saves time of installation and increase accurate sealing force as well.

- As there is no scratch at the lower part of the valve, stagnant water is excellent because of no scale and no accumulated foreign particles.

- As lower part and lateral face of disk seat maintains maximum area for stagnant water and its quality is excellent (Utility Model Patent: No.0330632)

|

1

|

Cap (GCD 450) |

|

2

|

Packing Box (GCD 450) | |

|

3

|

Packing (O Ring: NBR), (EPDM) | |

|

4

|

Cover (GCD 450) | |

|

5

|

Stem Nut (C3771 of KSD5101 or CAC406 of KSD6024) | |

|

6

|

Rubber Disk (Ductile iron casting: GCD450+Rubber for water works:EPDM), Utility Model Patent: No.0330632 | |

|

7

|

Packing for prevention from foreign particles, Utility Model Patent: No.0224565 | |

|

8

|

Hexagonal Bolt, Nut (Stainless Round Bar: STS 304) | |

|

9

|

Bush (3 Fluoride Ethylene Resin: Delrin) | |

|

10

|

Valve stem(STS410). (304) | |

|

11

|

Gasket Ring(NBR) | |

|

12

|

Flange packing attached type(NBR), (EPDM) Utility Model Patent: No.0224565 | |

|

13

|

Body (GCD 450) |

Specification

|

ND

|

L

|

Flange

|

T2

|

Spin

No.(+3) |

H1

|

H2

|

||||

|

D

|

C

|

g

|

txf

|

N-Øh

|

||||||

|

50

|

180

|

155

|

120

|

100

|

16x2

|

4-19

|

7

|

9

|

380

|

-

|

|

80

|

240

|

200

|

160

|

133

|

18x2

|

4-19

|

8

|

14

|

400

|

100

|

|

100

|

250

|

220

|

180

|

153

|

18x2

|

8-19

|

9

|

17

|

450

|

110

|

|

150

|

280

|

285

|

240

|

209

|

22x2

|

8-23

|

10

|

19

|

570

|

143

|

|

200

|

300

|

340

|

295

|

264

|

22x2

|

8-23

|

10

|

25

|

670

|

170

|

|

250

|

380

|

395

|

350

|

319

|

24x2

|

12-23

|

12

|

26

|

730

|

197

|

|

300

|

400

|

445

|

400

|

367

|

24x3

|

12-23

|

12

|

31

|

800

|

223

|

|

350

|

430

|

505

|

460

|

427

|

26x3

|

16-23

|

14

|

36

|

885

|

253

|

|

400

|

470

|

565

|

515

|

477

|

28x3

|

16-28

|

16

|

34

|

960

|

282

|

|

500

|

530

|

670

|

620

|

582

|

30x3

|

20-28

|

18

|

42

|

1118

|

335

|

| *Flange specifications: KSB2332(Korean Standard) (KSB 1511-10K) - depending on buyer's request *Foreign specifications is producible according to buyer's request *Electric Valve is producible according to buyer's request |

||||||||||

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

Related Products

Cast iron flanged ends OS Y gate valve BS5150 PN16 BS5163

High Pressure Bleed Valve (20,000 ~ 30,000 psi)

STEP VALVE

Flange

FR Coating